Desulfurization activated coke and method for preparing same

A technology for desulfurization of active coke and coal tar, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve problems such as production reduction, and achieve the effects of simple process, low price and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

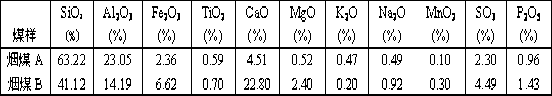

[0023] Raw material composition and ratio: Bituminous coal A60% (mass percentage), bituminous coal B 10% (mass percentage), coal tar 30% (mass percentage);

[0024] Preparation method: (1) Grinding: Crushing the raw materials of bituminous coal A and bituminous coal B to a particle size of 250 meshes; (2) Forming: uniformly mixing the pulverized raw materials of bituminous coal A and bituminous coal B with coal tar in proportion, and mixing them at 1000kgf / Extruded into carbon strips under a pressure of cm2 and air-dried for aging; (3) Carbonization: Carbonize the aged carbon strips to generate carbonized materials. The final carbonization temperature is 600°C, the carbonization time is 50min, and the heating rate is 2min / °C; ( 4) Activation: The carbonized material is activated by passing water vapor, the activation temperature is 800°C, and the activation time is 30 minutes to obtain an activated coke product with a particle size of 9mm.

Embodiment 2

[0026] Raw material composition and ratio: Bituminous coal A52% (mass percentage), bituminous coal B 20% (mass percentage), coal tar 28% (mass percentage);

[0027] Preparation method: (1) Grinding: Crushing the raw materials of bituminous coal A and bituminous coal B to a particle size of 300 meshes; (2) Forming: uniformly mixing the pulverized raw materials of bituminous coal A and bituminous coal B with coal tar in proportion, and mixing them at 900kgf / Extruded into carbon strips under a pressure of cm2 and air-dried for aging; (3) Carbonization: Carbonize the aged carbon strips to generate carbonized materials. The final carbonization temperature is 500°C, the carbonization time is 80min, and the heating rate is 6min / °C; ( 4) Activation: The carbonized material is activated by passing water vapor, the activation temperature is 850°C, and the activation time is 40 minutes to obtain an activated coke product with a particle size of 9mm.

Embodiment 3

[0029] Raw material composition and ratio: bituminous coal A 40% (mass percentage), bituminous coal B 30% (mass percentage), coal tar 30% (mass percentage);

[0030] Preparation method: (1) Grinding: Crushing the raw materials of bituminous coal A and bituminous coal B to a particle size of 180 meshes; (2) Forming: uniformly mixing the pulverized raw materials of bituminous coal A and bituminous coal B with coal tar in proportion, and mixing them at 800kgf / Extruded into carbon strips under a pressure of cm2 and air-dried for aging; (3) Carbonization: Carbonize the aged carbon strips to generate carbonized materials. The final carbonization temperature is 650°C, the carbonization time is 30min, and the heating rate is 4min / °C; ( 4) Activation: The carbonized material is activated by passing water vapor, the activation temperature is 850°C, and the activation time is 60 minutes to obtain an activated coke product with a particle size of 9mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap