Method and apparatus for rapidly ageing wine

A wine and equipment technology, applied in the preparation of alcoholic beverages, can solve the problems of long brewing time, unfavorable industrialization and economic benefits, loss of taste, etc., so as to reduce the brewing aging time and increase the wine brewing capacity. , the effect of shortening the brewing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

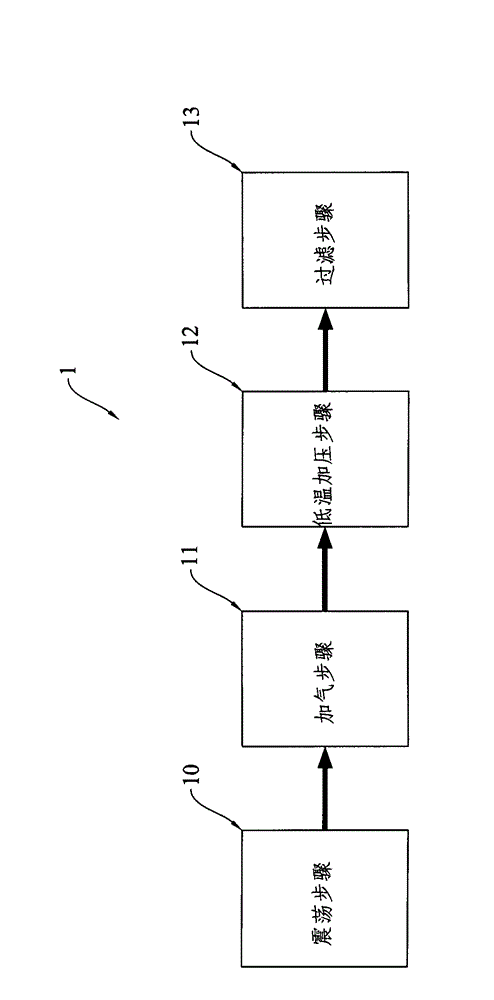

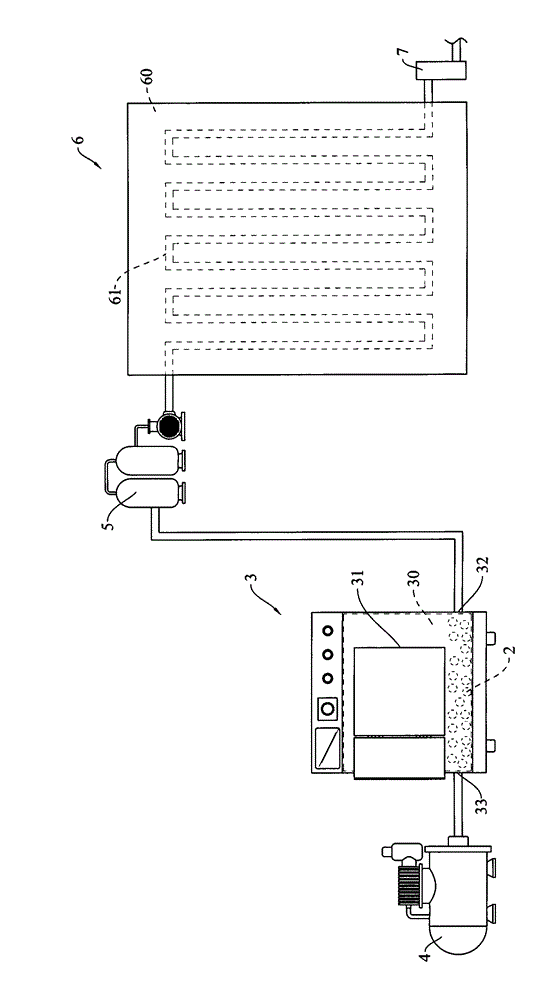

[0045] see Figure 1 to Figure 4 .

[0046] As shown in the figure, the method for rapid aging of wine according to Embodiment 1 of the present invention includes the following steps:

[0047] A. Vibration step 10: the wine product 2 is subjected to ultrasonic or magnetic wave vibration through the vibration device 3, so as to destroy the molecular structure of the wine product 2;

[0048] B. Adding gas step 11: the amount of oxygen is about 60mg / m 3 up to 80mg / m 3 The air is injected into the wine product 2, and then oscillated by ultrasonic waves or magnetic waves, so that the oxygen and the molecular structure of the wine product 2 are re-fused;

[0049] C. Low-temperature pressurization step 12: Use low-temperature pressurization to make the wine product 2 at a temperature of about 1 to 15°C and a pressure of about 5kg / m 2 up to 20kg / m 2 Within the range of , its molecular structure is re-fused, thereby shortening the brewing time, so as to improve the brewing aging e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com