Household paper coating apparatus and coating method

A technology for coating device and household paper, which is applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of instability, increased fire hazard, uneven distribution of household paper odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

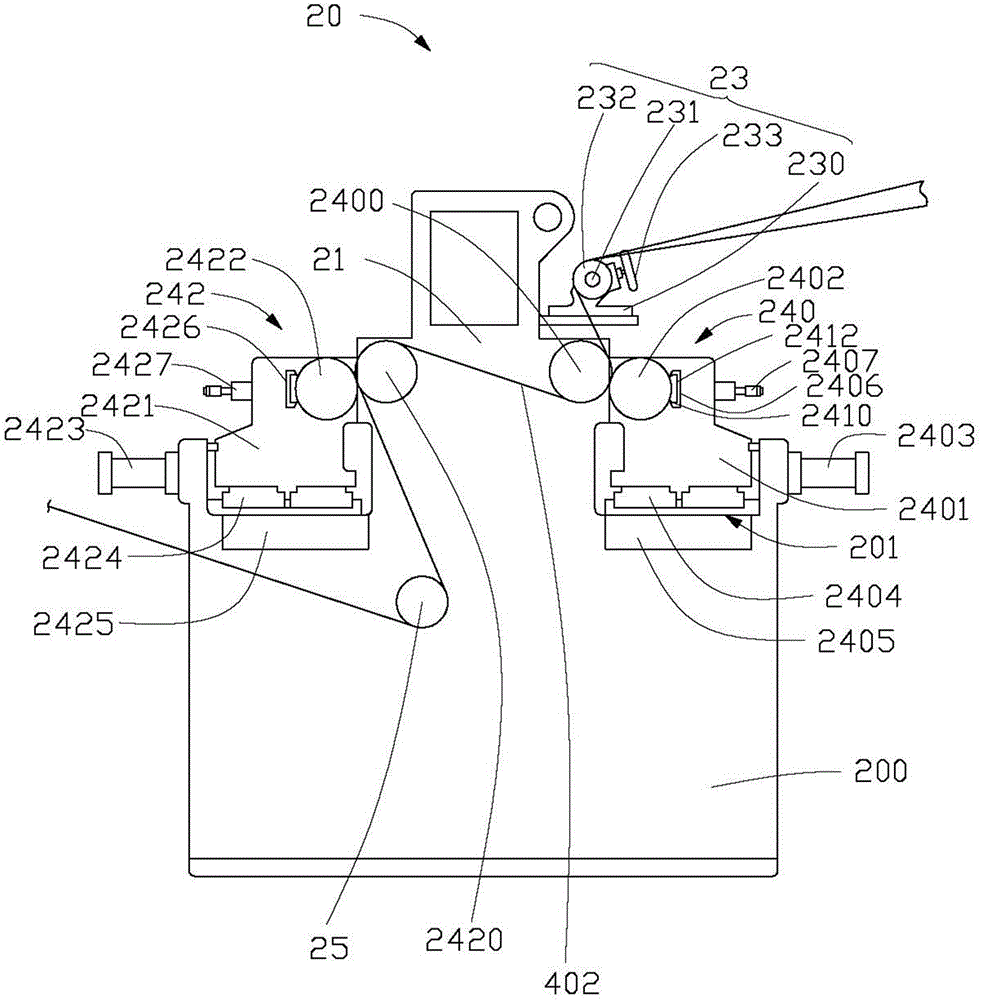

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

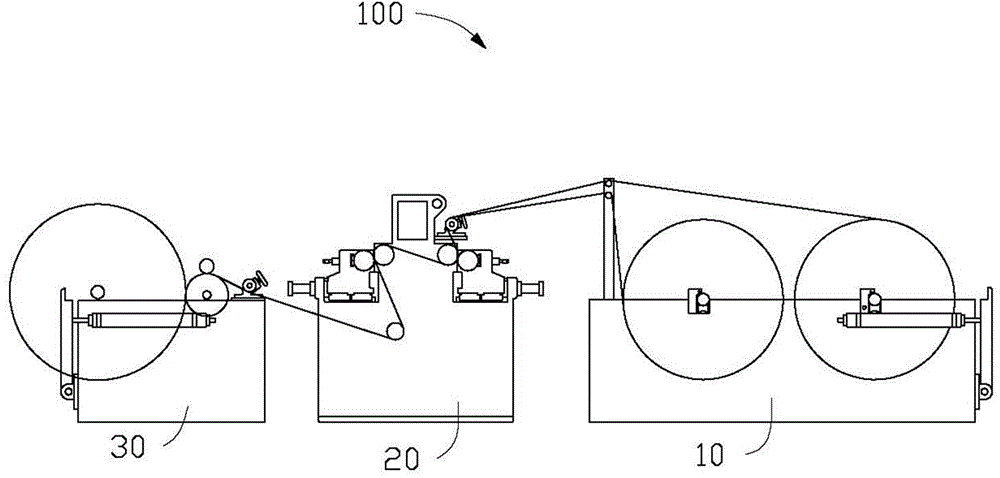

[0018] see figure 1 , the embodiment of the present invention provides a household paper coating device 100, which is used for coating and adding liquid additives to household paper. The liquid additive can be an odor additive, or other functional additives, such as moisturisers and the like. The coating device 100 includes an unwinding unit 10 , a coating unit 20 and a reprocessing unit 30 arranged in sequence.

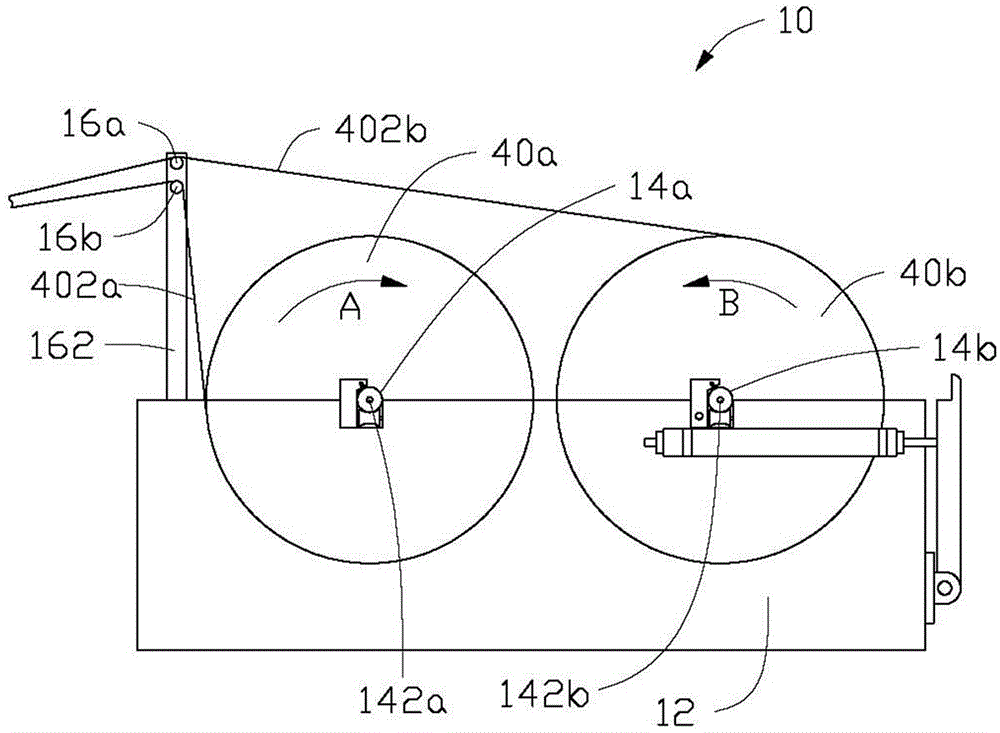

[0019] Please also refer to figure 1 and figure 2 , in this embodiment, the unwinding unit 10 includes a first base 12, two unwinding rollers 14a and 14b and two guide rollers 16a and 16b.

[0020] The two unwinding rollers 14a and 14b have rotating shafts 142a and 142b respectively, and the rotating shafts 142a and 142b are parallel to each other. In this embodiment, the rotating shafts 142a and 142b are adjacent to and far fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com