Ceramic tile paving method

A laying method and technology of ceramic tiles, applied in covering/lining, construction, building construction, etc., can solve the problems of easy collection of dirt, etc., and achieve the effect of convenient cleaning of dirt and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

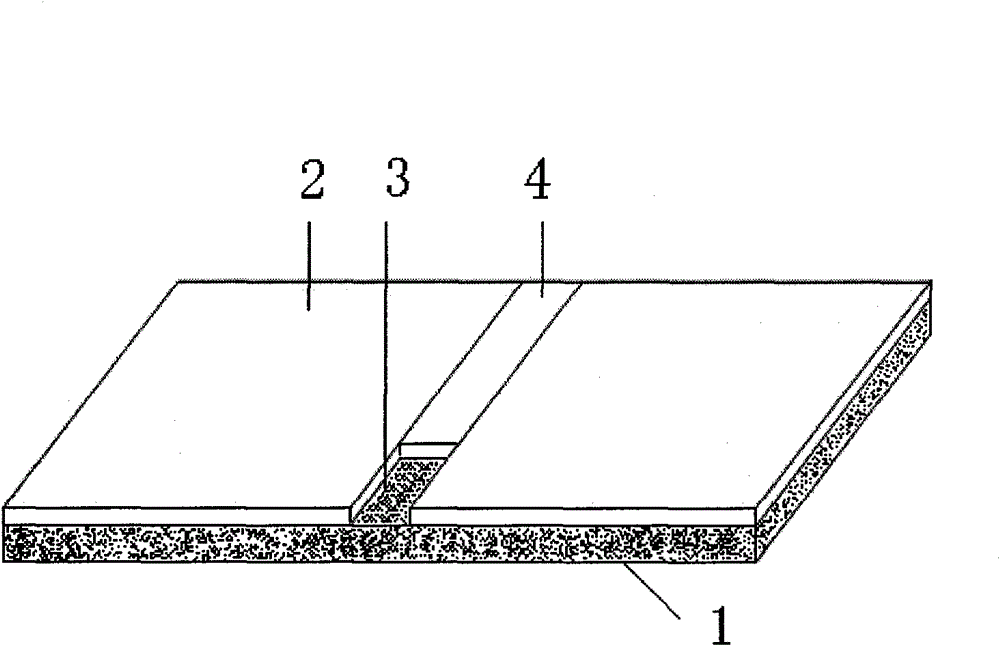

[0008] Such as figure 1 As shown, a cement mortar layer 1 is laid on the ground to prepare for carrying and bonding ceramic tiles 2 . Paste tiles 2 on the cement mortar layer 1, and the distance between tiles 2 is 3 cm. After the cement mortar layer 1 is solidified and fixed, the rubber bead 4 is filled in the groove 3 between the ceramic tiles 2, the width of the rubber bead is 3 cm, and the rubber bead 4 and the ceramic tile 2 are kept flat. When dirt is collected in the gap between the ceramic tile 2 and the rubber bead 4 and obvious traces appear, the rubber bead 4 is pulled out from the groove 3 for cleaning. After cleaning, the rubber bead 4 is filled in the groove 3. In addition, the rubber bead 4 is located between the tiles 2, making the tiles 2 discontinuous with each other, thus having anti-skid performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com