A backward centrifugal fan for a range hood and the range hood

A technology of centrifugal fans and range hoods, which is applied to parts of pumping devices for elastic fluids, oil fume removal, machines/engines, etc. It can solve problems such as fan function failure, broken flow channel lines, and excessive grease. Achieve the effects of easy cleaning, improved flow efficiency, and less dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

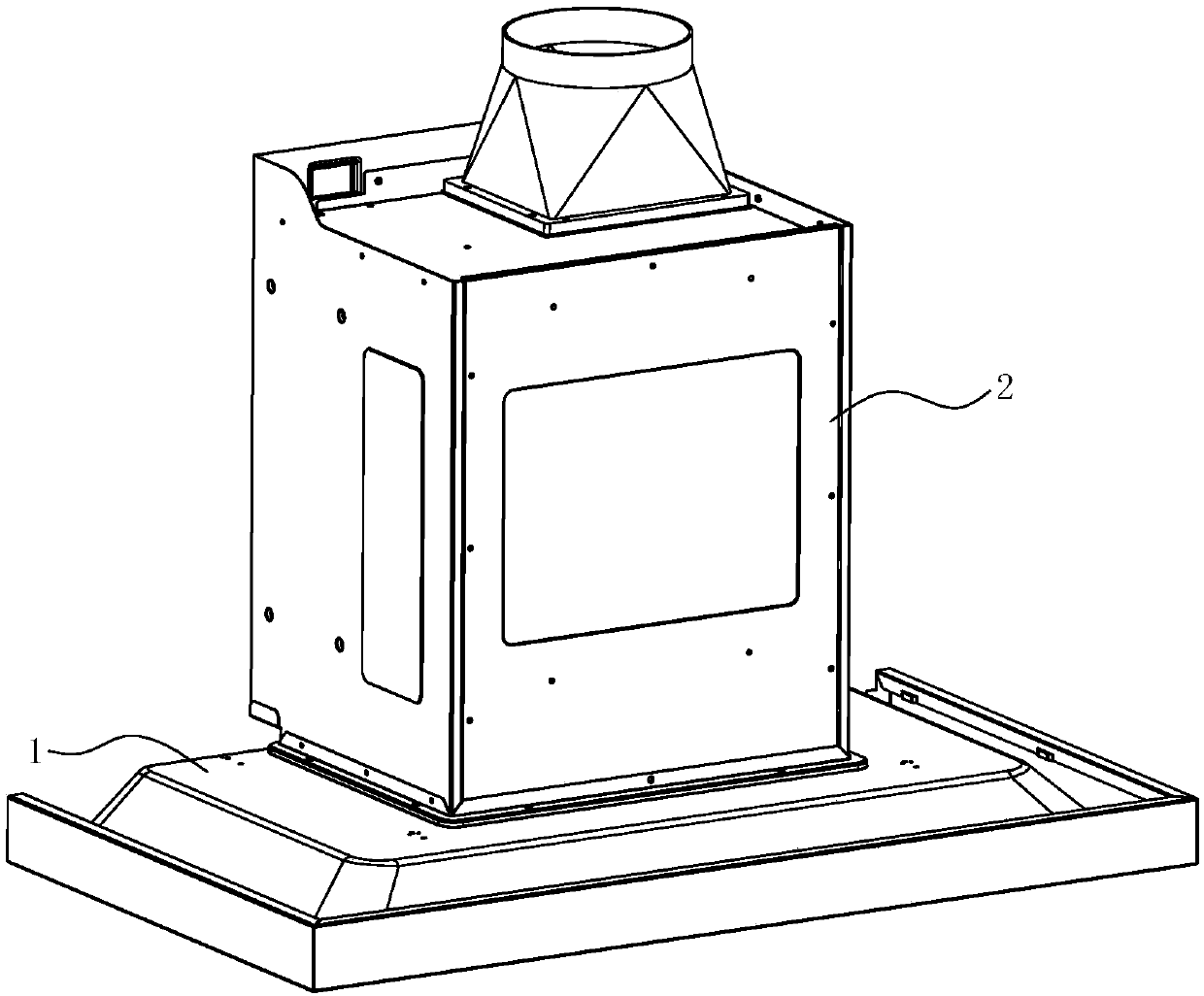

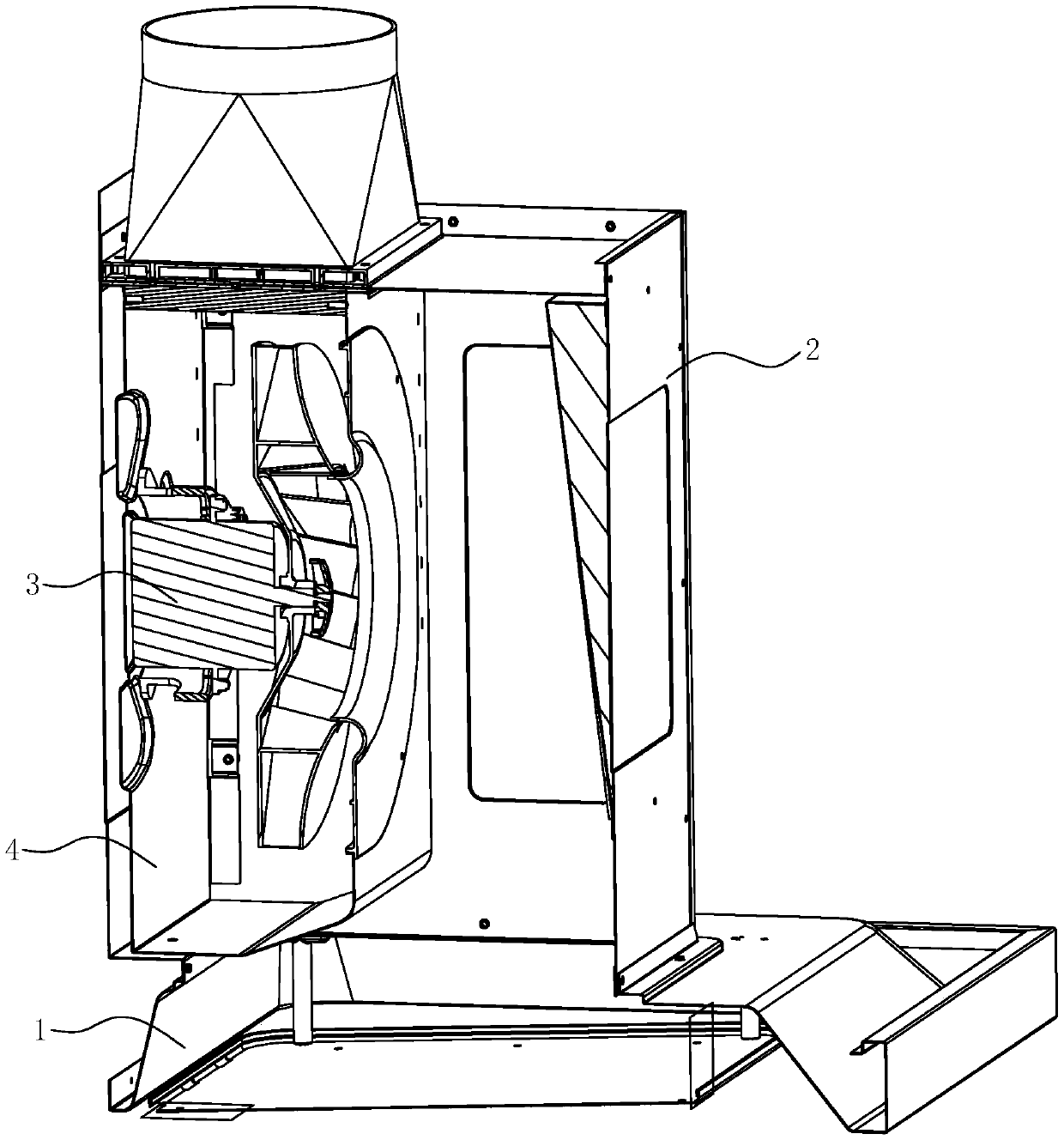

[0030] see Figure 1 to Figure 6 , a range hood, including a fume collection hood 1 and a chassis 2 located above the fume collection hood 1, for the convenience of description, hereinafter, "front", "rear", "left", "right", "upper", "Down" refers to the position of the range hood relative to the user when the user uses the range hood, and does not limit the structure.

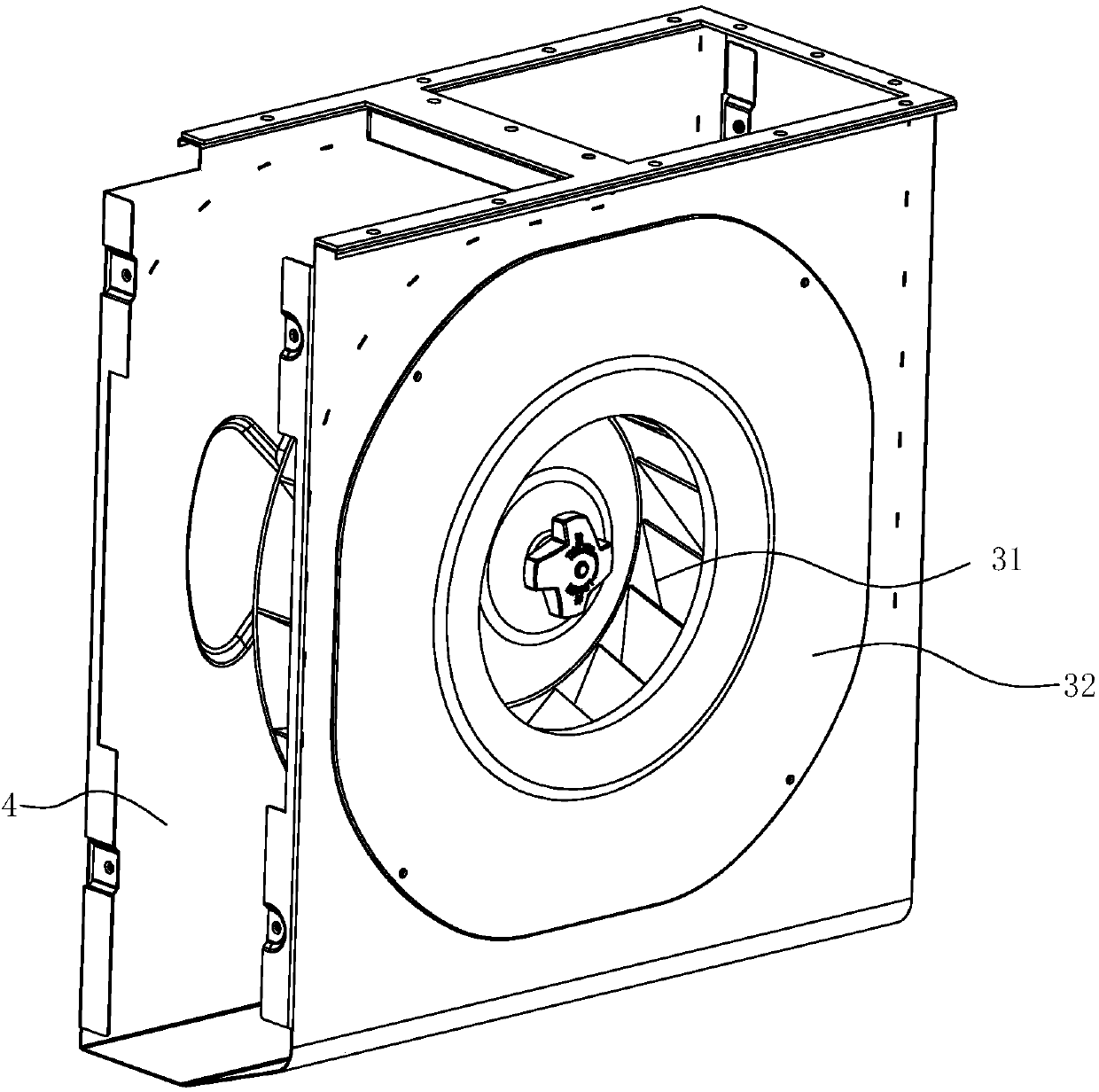

[0031] A fan system 3 is arranged inside the chassis 2 , and in this embodiment, the fan system 3 adopts a backward centrifugal fan, including an impeller 31 , an air inlet ring 32 and a driving motor 33 . Wherein, the impeller 31 includes a front disc 311, a rear disc 312 and a plurality of blades 313 arranged between the front disc 311 and the rear disc 312, as Figure 6 The middle arrow shows the direction of rotation of the impeller 31 .

[0032] The front plate 311 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com