Filtering tank

A filter tank and filter membrane technology, which is applied in the field of filter tanks, can solve the problems of unclean cleaning, short service life of roll-type membranes, and difficult cleaning of roll-type membrane dirt, so as to achieve the effect of easy and easy cleaning of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

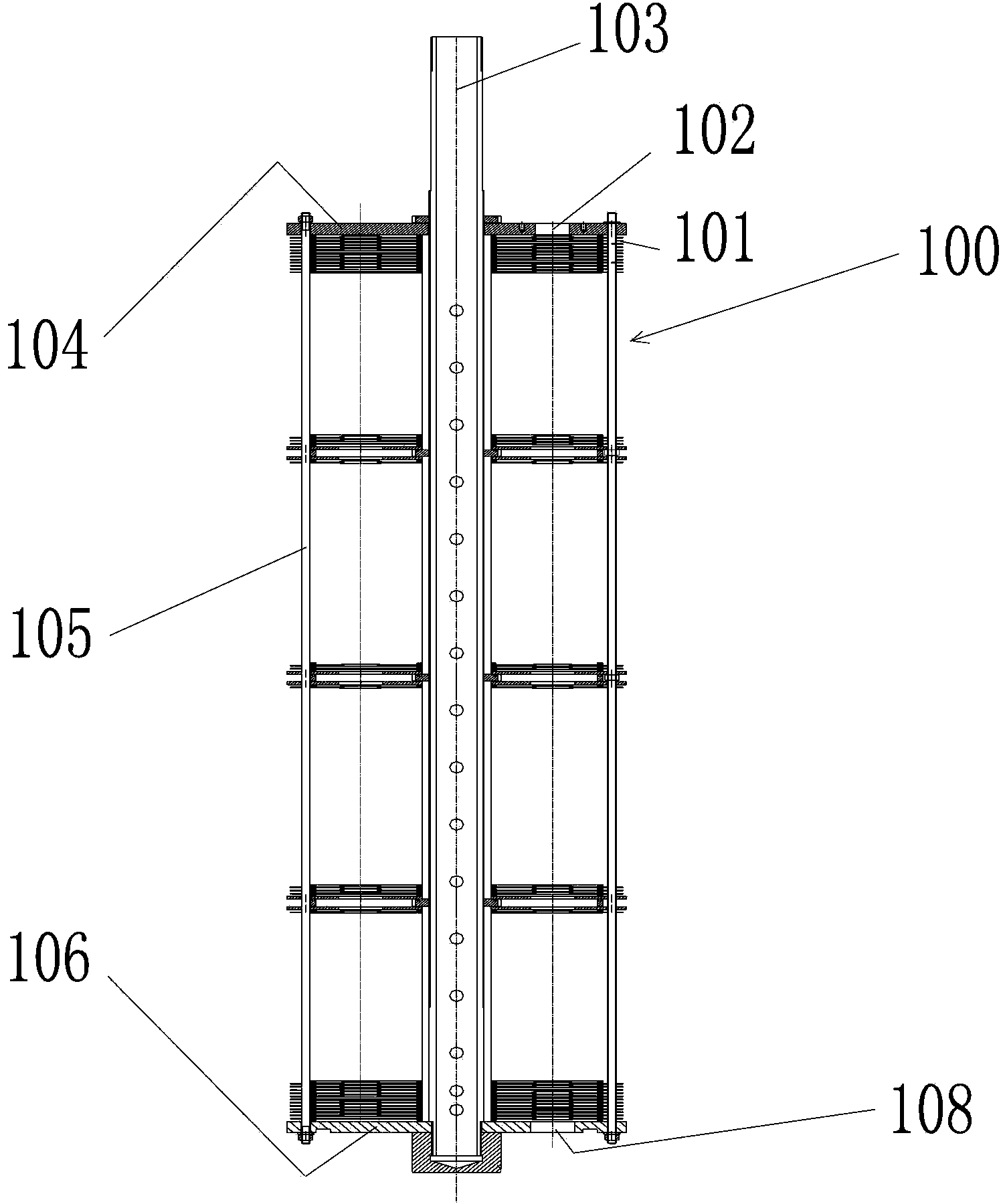

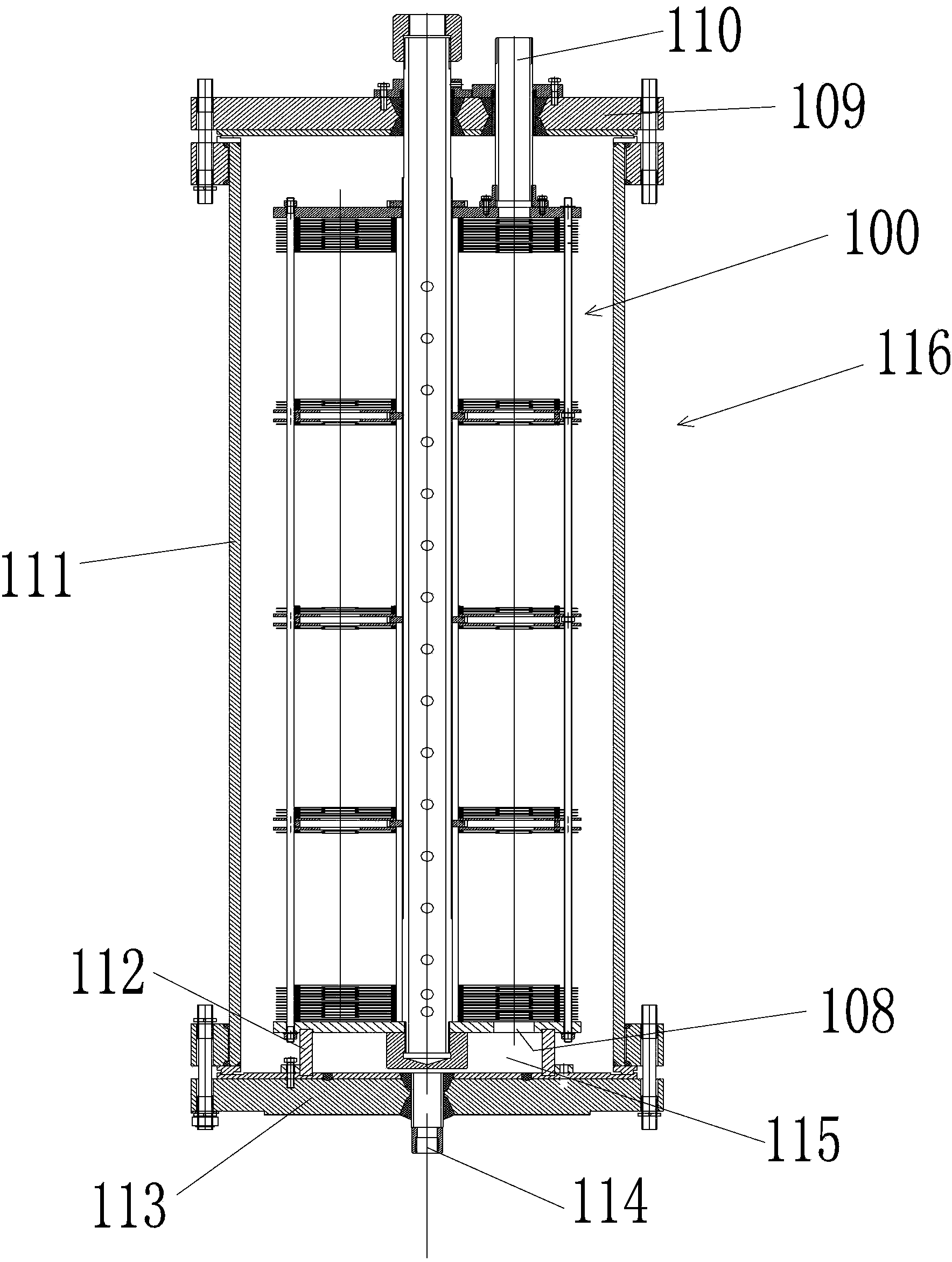

[0051] For the filter unit adopted by the filter core in the filter tank of the present invention, see Figure 3-Figure 7 The first embodiment and the second embodiment of the filter unit are described in detail as follows:

no. 1 example

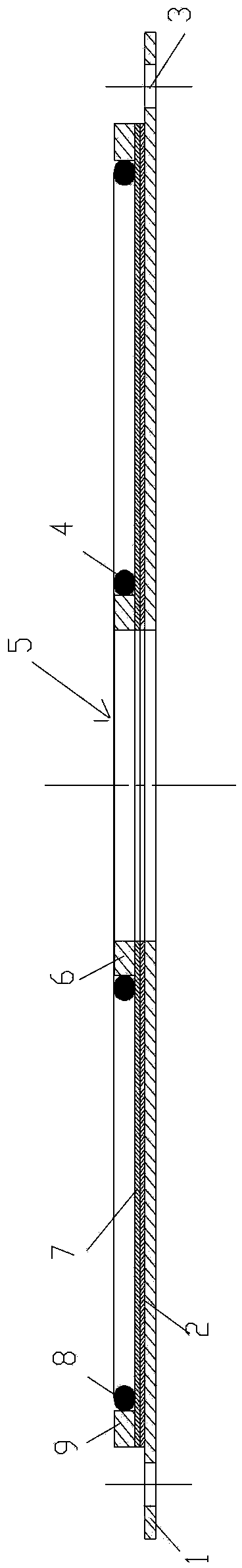

[0053] In order to facilitate a clear understanding of the filter unit in the present invention, first refer to image 3 omits the second perforation (in the Figure 4 Shown in detail) view description, combined with Figure 4 The filter unit showing the second perforation is fully described.

[0054] see image 3 As shown, in this embodiment, the filter unit includes: a stack of laminations, which are formed by a planar rigid water retaining sheet 1, a first filter screen 2, and a first filter membrane 7 stacked sequentially from bottom to top; Group and by water collection pipe 103 ( figure 1 Shown) the first perforation 5 that passes through; the first water retaining ring 6 and the second water retaining ring 9, these two water retaining rings are all laminated on the first filter membrane 7, and the first water retaining ring 6 is on the second In the surrounding area of the second water retaining ring 9 ; and the first perforation 5 is located in the surrounding ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com