Expansion type multi-grade pressurized rapid hole sealing technology

An expansive and hole-sealing technology, which is applied in sealing/isolation, gas discharge, safety devices, etc., can solve the problems of short service life, high cost, and low concentration of gas drainage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

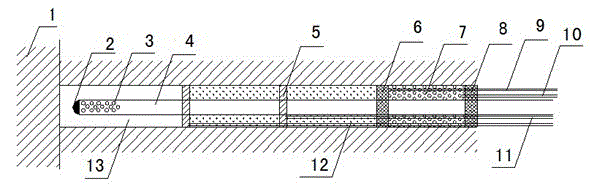

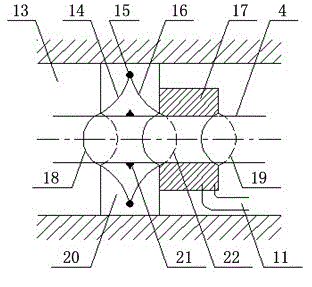

[0019] In the figure, the device used in the expansive multiple pressure rapid sealing technology is provided with a tubular extraction pipe 4, the top of the extraction pipe 4 is provided with an extraction pipe plug 2, and the front end of the extraction pipe 4 is evenly There are sealing holes 3, and the extraction pipe 4 is installed with a plurality of inflatable sealing bags 5 sequentially from front to back. The inflatable sealing bags 5 are separated by a polymer foam material I6 for a certain distance, and the holes in the drilling holes 13 are drained. The mouth is provided with a polymer foam material II8 for sealing, the tubular grouting pipe I9 and the grout outlet pipe 10 extend through the polymer foam material II8 into the sealing space of the sealing section, and the tubular grouting pipe II11 is sequentially Pass through the polymer foam material II8, the sealing space of the sealing section and the polymer foam material I6, and enter the expansion sealing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com