Plasma display panel and green phosphor layer

A green fluorescent and display panel technology, which is applied in the direction of AC plasma display panels, fluorescent layers, luminescent materials, etc., can solve problems such as poor color purity, reduced brightness, and shortened afterglow time of green phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

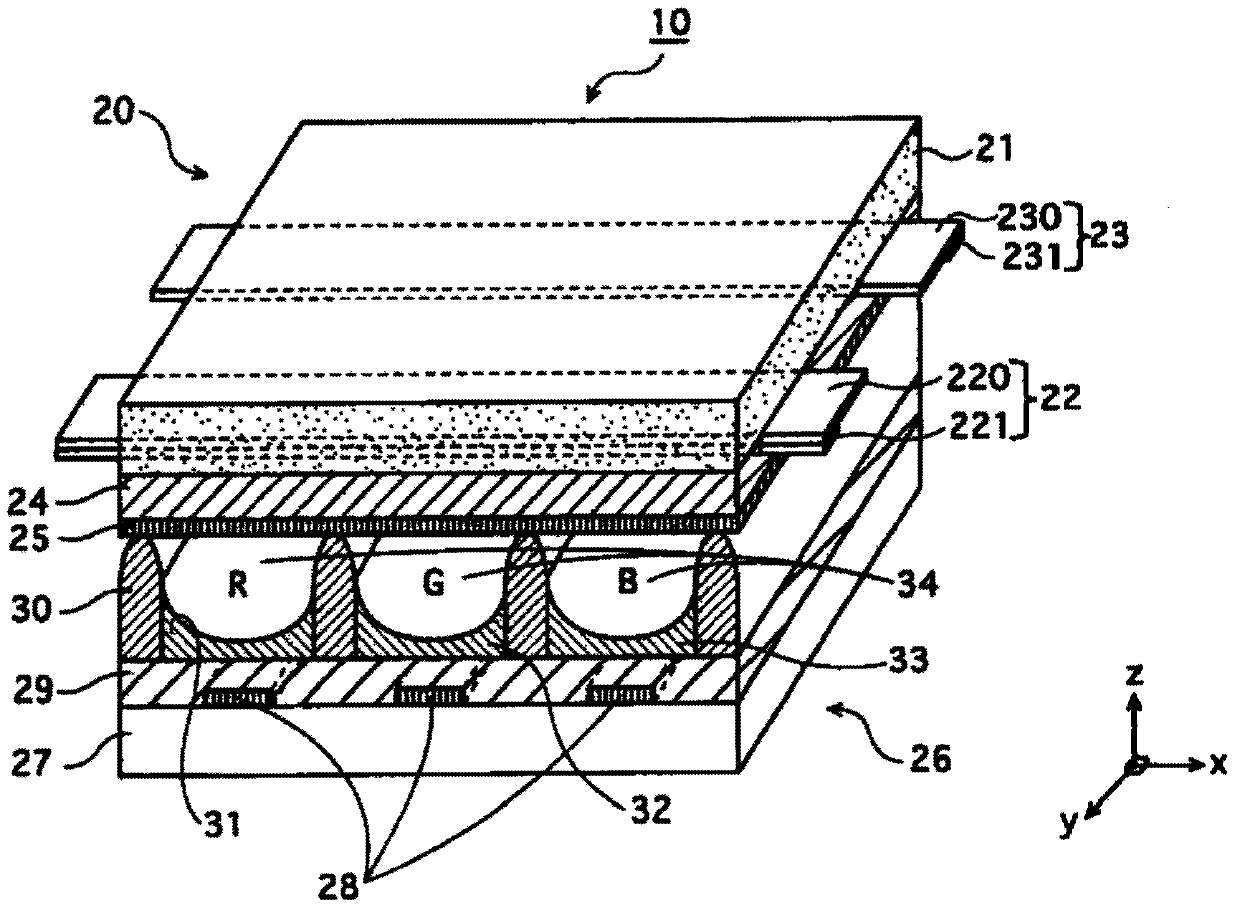

[0028] Hereinafter, embodiments of the present invention will be described in detail.

[0029]

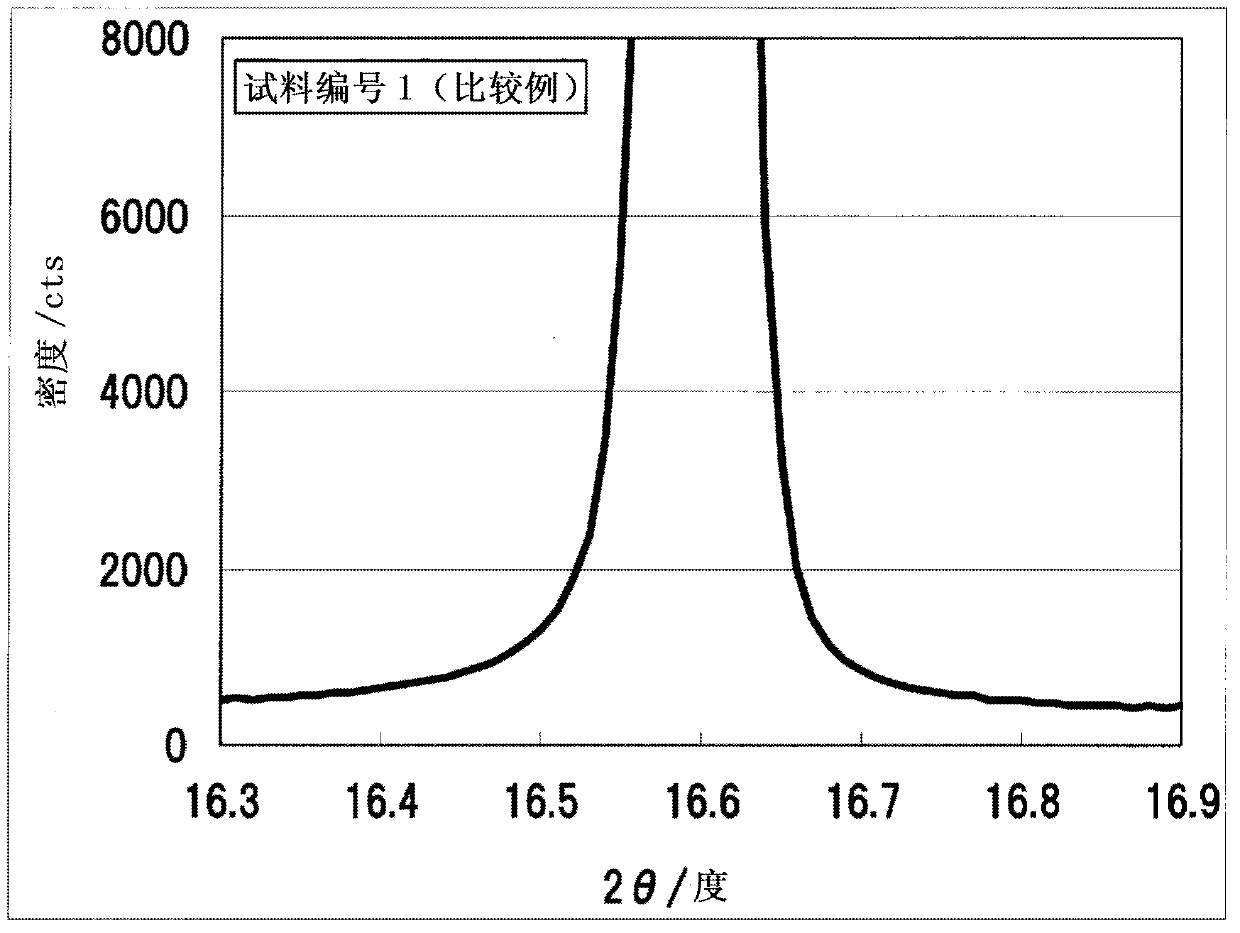

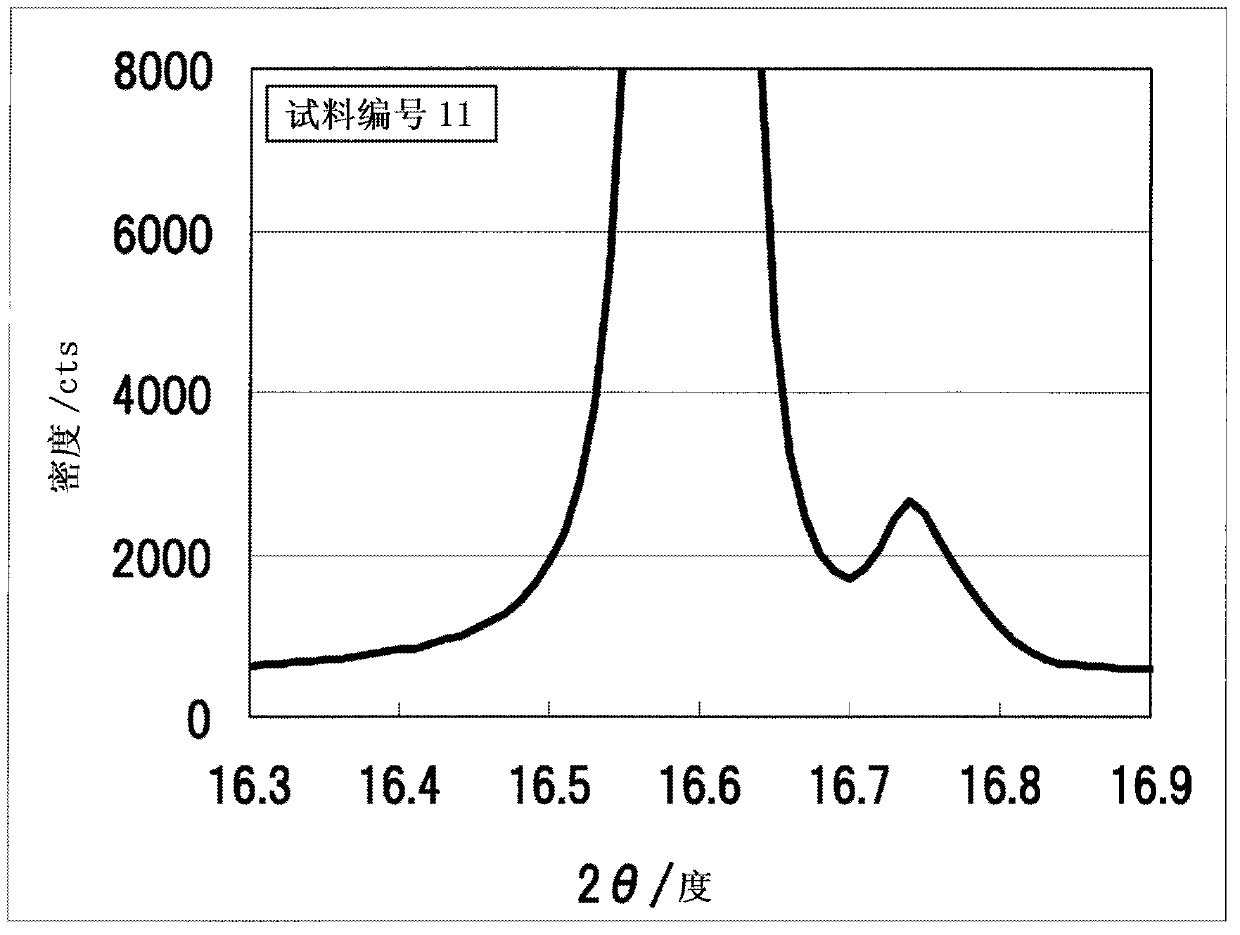

[0030] The first phosphor used in the present invention is represented by the general formula aYO 3 / 2 ·(3-a)CeO 3 / 2 · bAlO 3 / 2 ·cGaO 3 / 2 (2.80≤a≤2.99, 1.00≤b≤5.00, 0≤c≤4.00, where 4.00≤b+c≤5.00) means. Regarding a, a preferable range is 2.97≦a≦2.99 from the viewpoint of brightness. The first phosphor is characterized by the wavelength In the X-ray diffraction pattern measured by X-rays, there is a peak in the range where the diffraction angle 2θ is not less than 16.7 degrees and not more than 16.9 degrees.

[0031] The present inventors have found through detailed examination based on experimental results that a phosphor having high luminance and color purity can be obtained from a phosphor having the above-mentioned composition and conforming to the above-mentioned characteristics regarding the X-ray diffraction pattern. in the existing Y 3 al 5 o 12 : In the Ce phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com