A warm white phosphor excited by UV LEDs

A phosphor and warm white technology, applied in the field of rare earth luminescent materials, can solve the problems of poor stability, high cost and low excitation efficiency of phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

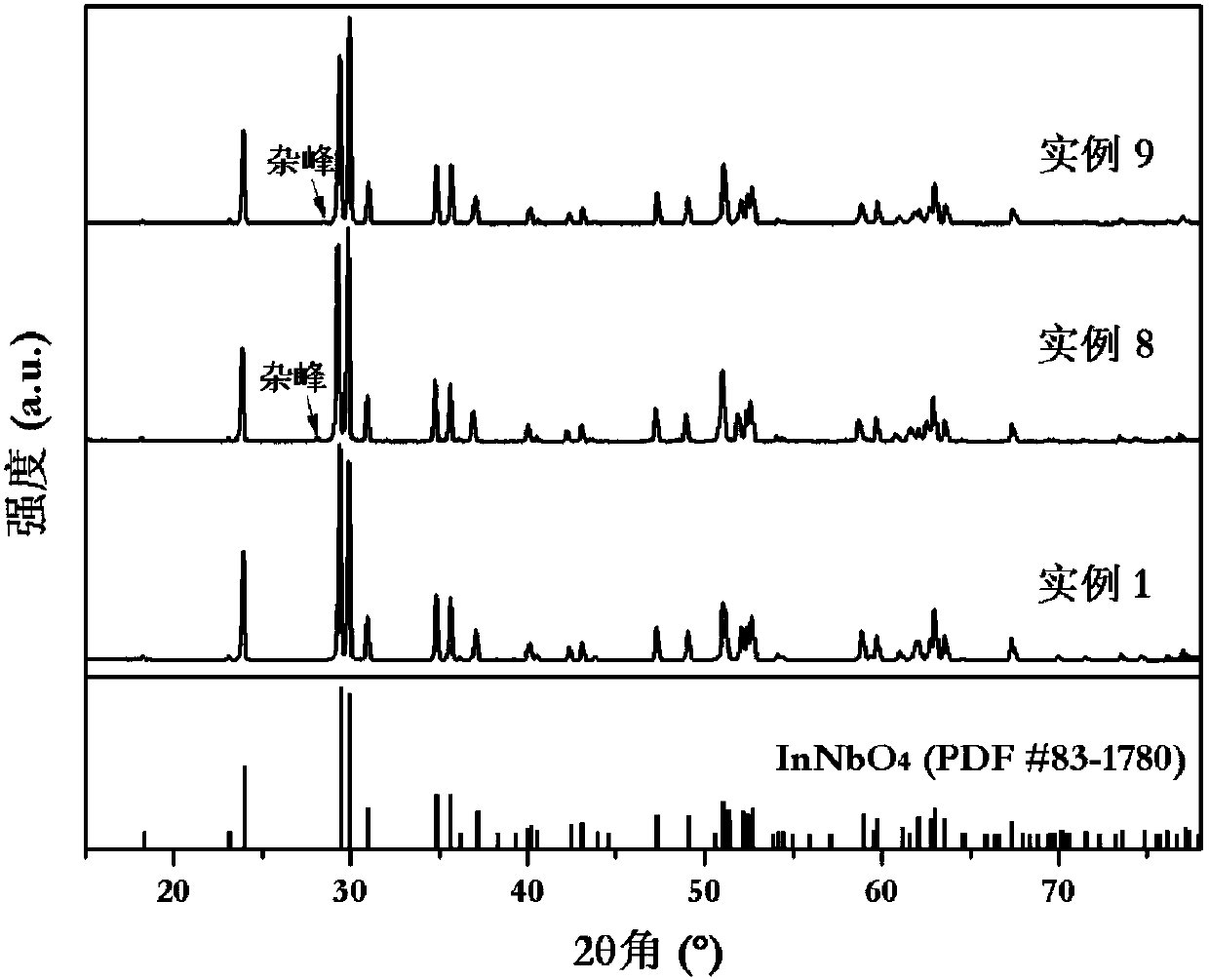

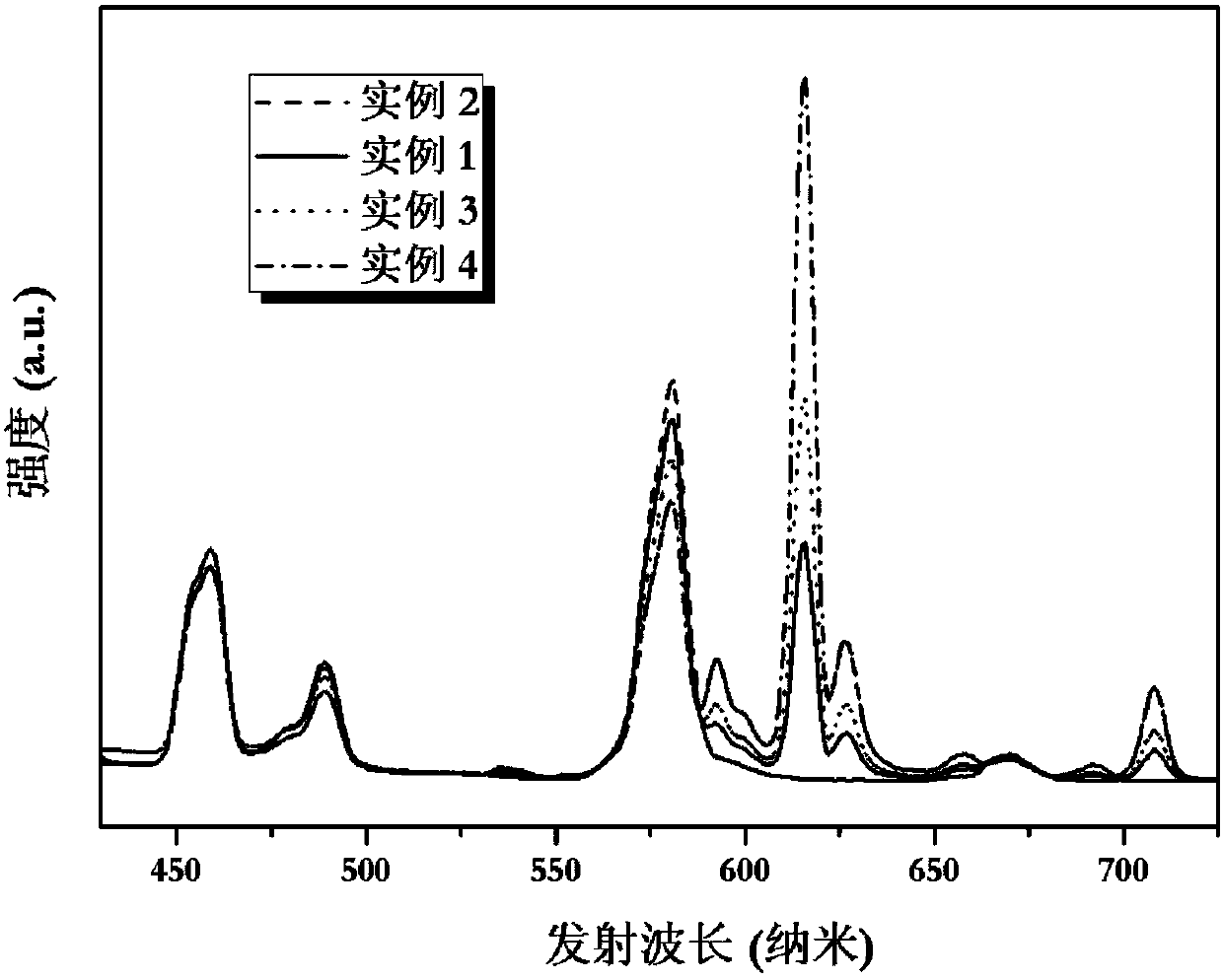

[0033] Example 1: In 0.974 Dy 0.01 T m 0.01 Eu 0.006 NbO 4 Phosphor powder preparation

[0034] Weigh 0.9701g Nb 2 o 5 , 0.9869g In 2 o 3 , 0.0136g Dy 2 o 3 , 0.0141g Tm 2 o 3 and 0.0077g Eu, and ground it in an agate mortar for 15 minutes to mix the raw materials evenly. The mixed raw materials were placed in a corundum crucible, and the temperature was raised to 1000°C in a resistance furnace at a rate of 5°C / min for the first-stage sintering, and the sintering time was 12h. Then cool down with the furnace, grind the sintered product for 10 minutes, and then raise the temperature to 1250°C at a speed of 5°C / min for the second-stage sintering, and the sintering time is 24h. Grinding after cooling in the furnace, the composition can be obtained as In 0.98 Dy 0.01 T m 0.01 NbO 4 of fluorescent powder.

Embodiment 2

[0035] Example 2: In 0.98 Dy 0.01 T m 0.01 NbO 4 Phosphor powder preparation

[0036] Weigh 0.9701g Nb 2 o 5 , 0.9930g In 2 o 3 , 0.0136g Dy 2 o 3 and 0.0141g Tm 2 o 3 , the rest of the steps are the same as in Example 1.

Embodiment 3

[0037] Example 3: In 0.97 Dy 0.01 T m 0.01 Eu 0.01 NbO 4 Phosphor powder preparation

[0038] Weigh 0.9701g Nb 2 o 5 , 0.9869g In 2 o 3 , 0.0136g Dy 2 o 3 , 0.0141g Tm 2 o 3 And 0.0128g Eu, all the other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com