Vertical open explosion tank with separable tank body and bottom

An explosion tank and tank body technology, applied in the field of explosion tanks, can solve the problems of weakening the service life of the air shock wave tank body, prolonging the explosion interval time, and increasing the cost of the explosion, so as to reduce the impact of the air shock wave on the tank wall and recover The effect of reducing the loss rate and reducing the recovery loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

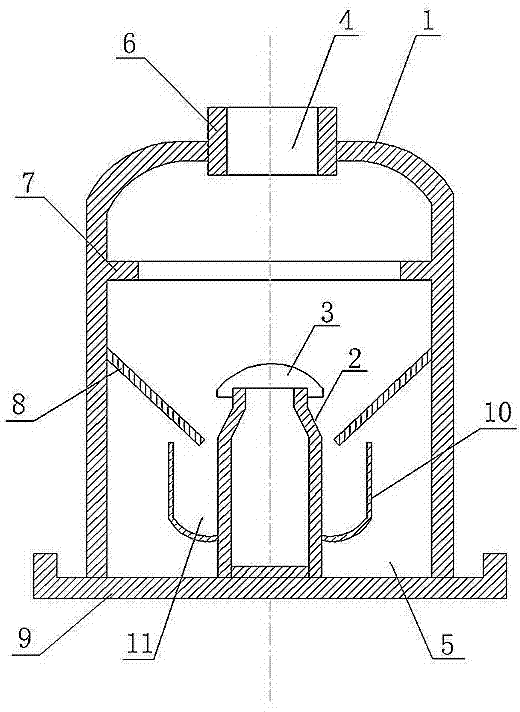

[0017] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: the same as the prior art, there is a tank body 1, in the tank body 1 is provided with a vertical receiving tank 2 and a water mist spraying device 3 with an inner diameter that is small at the top and large at the bottom. The difference from the prior art is that the tank The body 1 is vertically provided with an upper opening 4 and a lower opening 5, and the upper opening 4 is provided with a vertical retaining ring 6 whose lower end extends into the tank body 1, and the height deep in the tank body 1 is preferably 2 ~25cm, a circle of transverse retaining ring 7 is connected to the upper part of the inner wall of the tank body 1, the horizontal width of the transverse retaining ring 7 is preferably 2~20cm, and a circle of return plates 8 whose inner end is inclined downward is connected to the middle of the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com