Temperature control device of centrifugal casting machine

A temperature control device and centrifugal casting technology, applied in the field of detection and control equipment, to achieve the effects of excellent performance, avoiding adverse effects and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

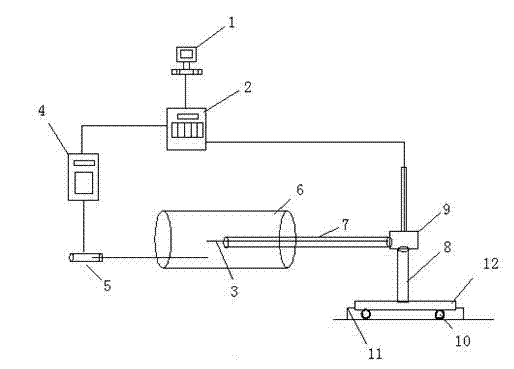

[0014] As shown in the figure, the present invention is composed of an industrial computer 1, a PLC control cabinet 2, and a temperature measuring trolley 12.

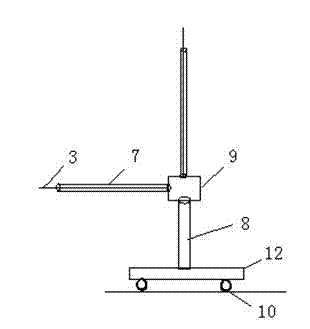

[0015] As shown in the figure, the temperature measuring trolley 12 includes a thermocouple 3 , a temperature measuring gun 7 , a T-shaped fixing bracket 8 and a junction box 9 .

[0016] The junction box 9 is installed on the T-shaped fixed bracket 8. The temperature measuring gun 7 is made of high temperature resistant stainless steel. One end of the temperature measuring gun 7 is connected to the junction box 9 through a bearing. The signal input ends of the PLC control cabinet 2 are connected to the junction box 9 respectively. It is connected with the industrial computer 1, and the thermocouple 3 is installed inside the temperature measuring gun 7, and the signal is transmitted to the PLC control cabinet through the junction box 9.

[0017] As shown in the figure, the signal input terminal of the PLC control cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com