Wheel for vehicle

A wheel and vehicle technology, applied in the direction of wheels, vehicle parts, spoke wheels, etc., can solve the problems of forming thick flanges, increasing the overall weight of the wheel, and increasing the size of the hub, achieving the effect of increasing thickness and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

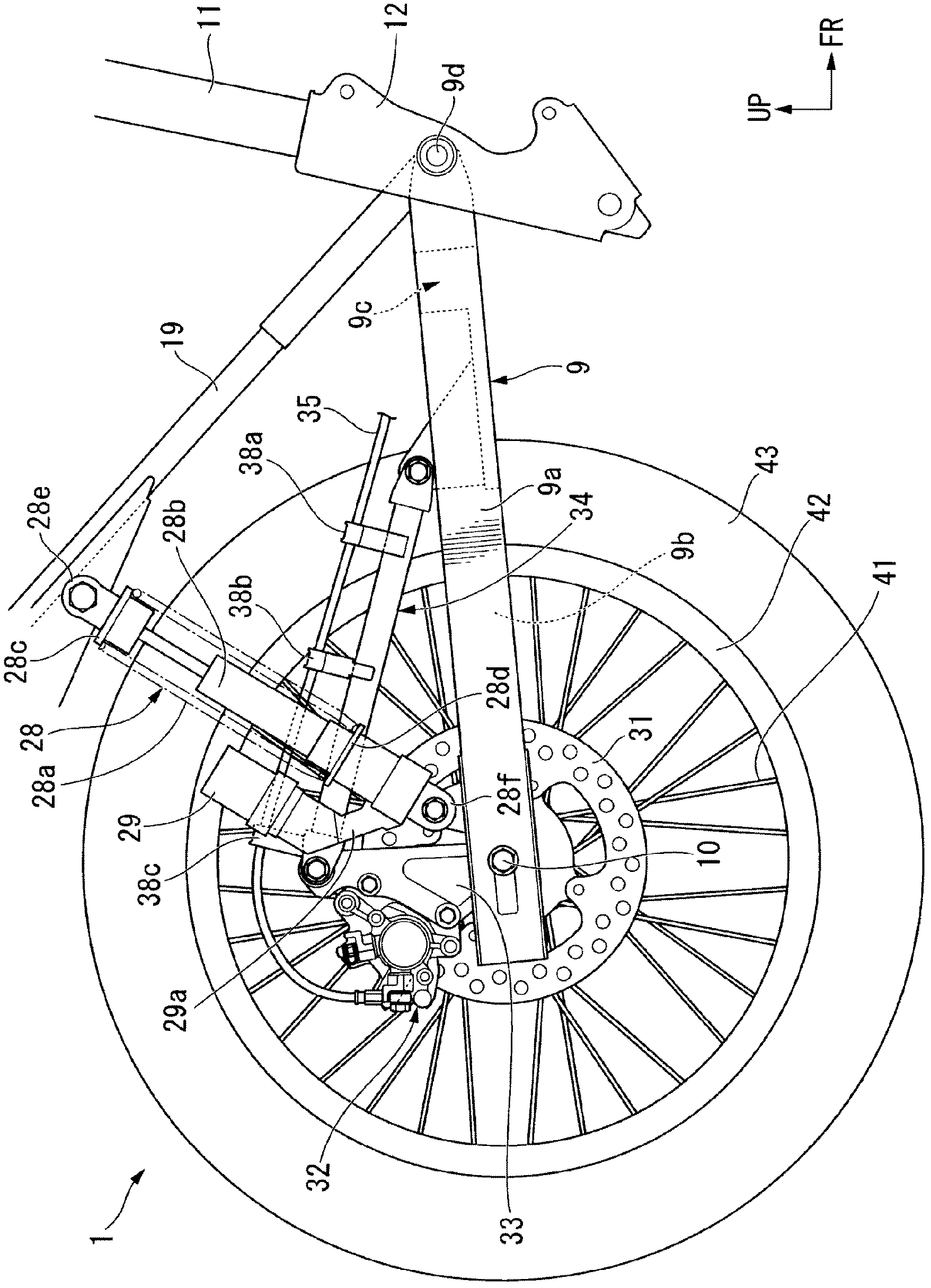

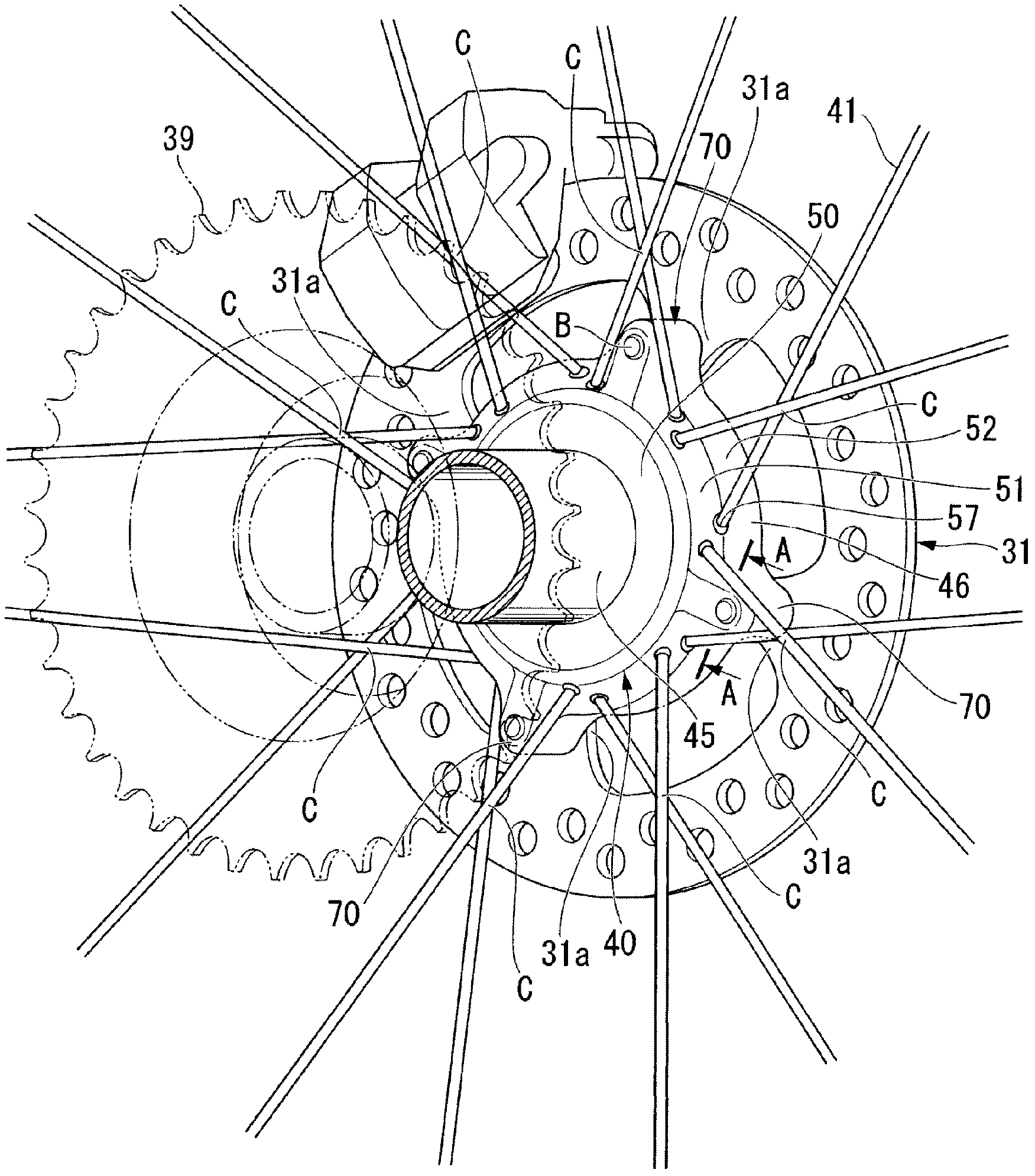

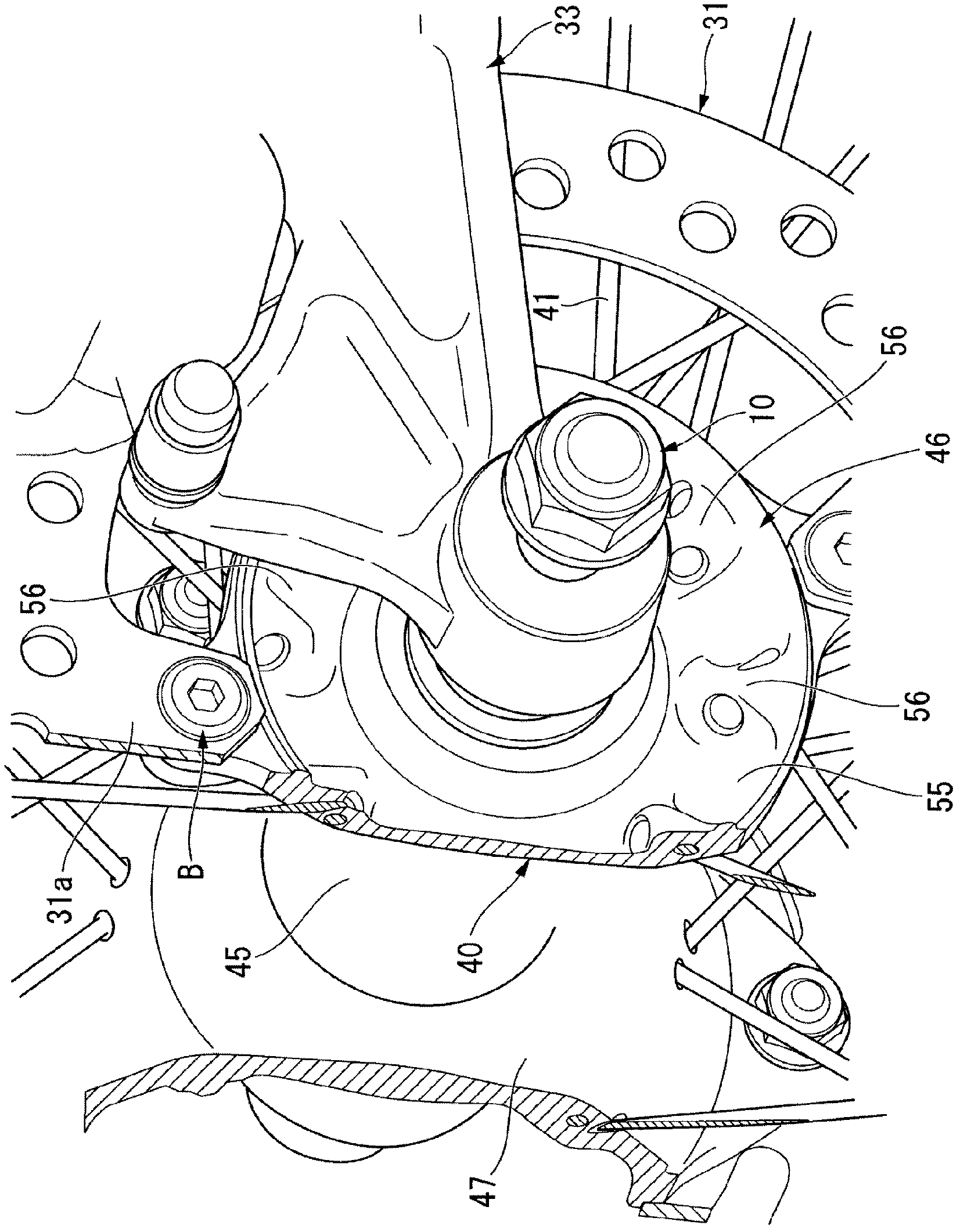

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, directions such as front, rear, left, and right in the following description are the same as directions in the vehicle described below unless otherwise specified. In addition, arrows FR indicating the front of the vehicle, arrows LH indicating the left side of the vehicle, and arrows UP indicating the upward direction of the vehicle are shown in the figures used in the following description.

[0045] Such as figure 1 As shown, the wheels of the vehicle of this embodiment are in the form of rear wheels of a motorcycle, and are pivotally supported by the rear portion of the swing arm 9 . The front end portion of the swing arm 9 is supported by a pivot bracket 12 integrally provided on the rear lower side of a main frame 11 of the vehicle. Between the pivot bracket 12 and a seat rail (not shown) extending substantially horizontally rearward from the rear rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com