Patents

Literature

45results about How to "Fully rigid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical self-expansion plugging device

InactiveCN101370432ABest memory performanceImprove deformation abilitySurgeryThin wireMedical treatment

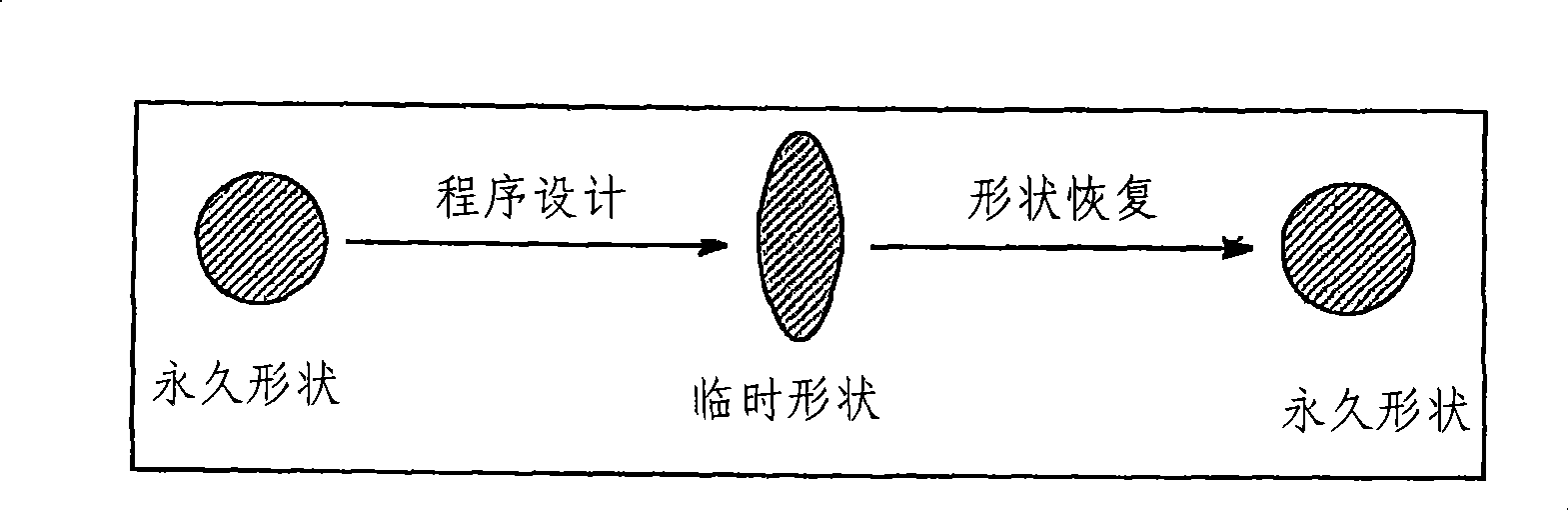

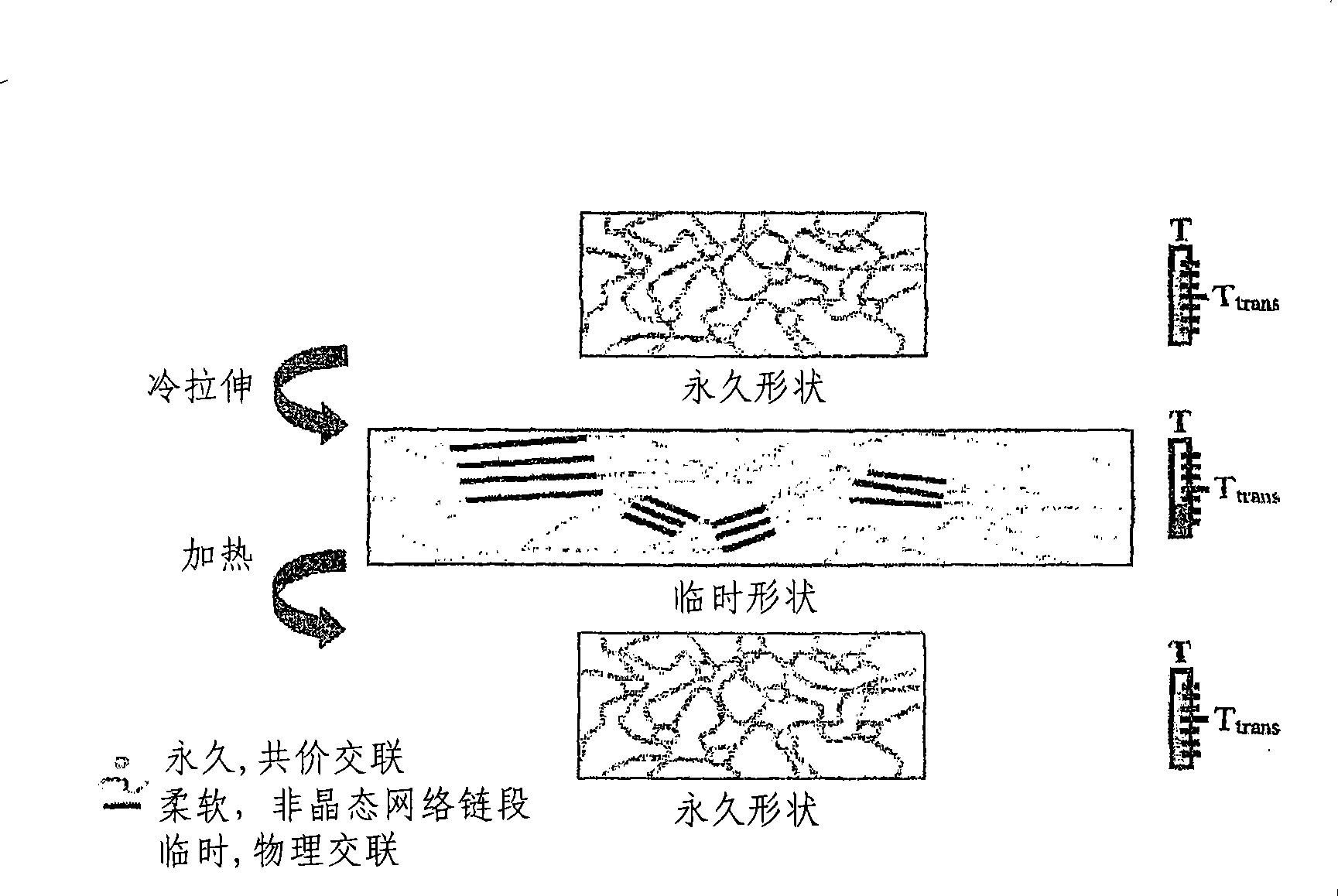

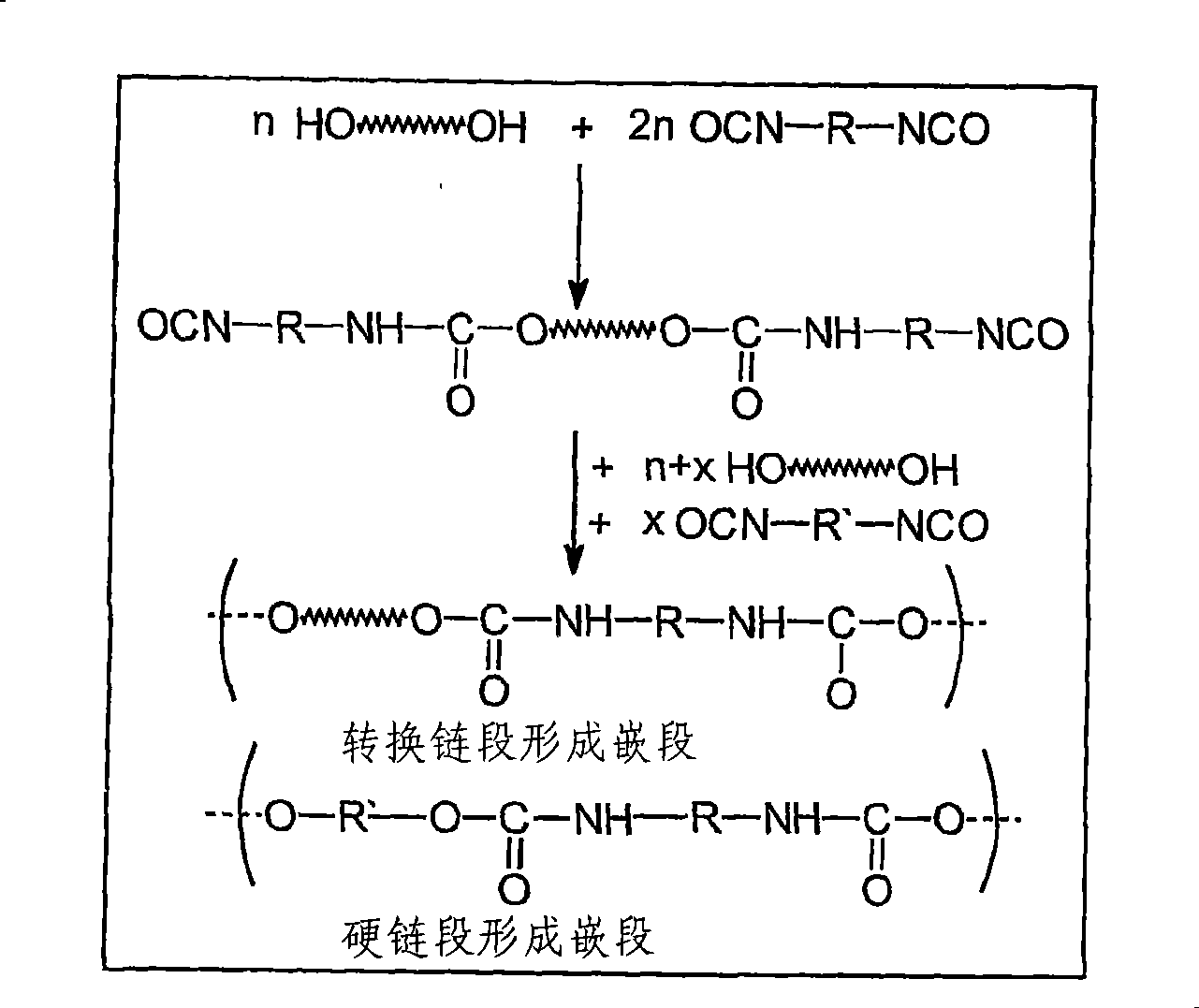

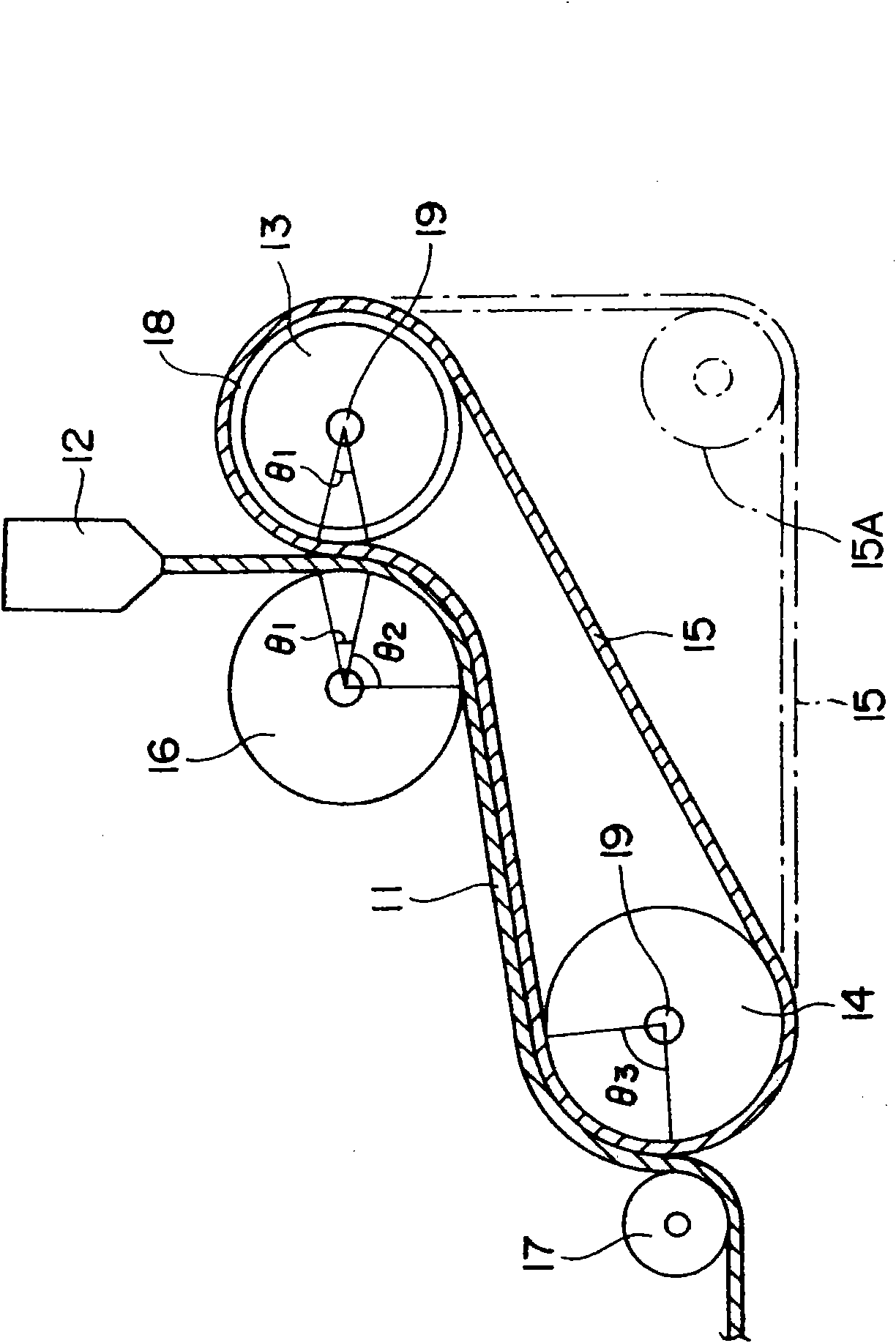

The invention relates to a medical self-expandable occlusion device for treating heart defects of a patient, especially for closing abnormal holes in the tissue. The occlusion device (1) can be inserted into the body of a patient by means of a catheter system in a minimally invasive manner. The occlusion device (1) consists of an interlaced structure (1) of thin threads, the interlaced structure (10) having a first shape during insertion of the occlusion device into the body of the patient, which shape can be previously determined, and a second shape in the implanted position of the occlusion device, which shape can be previously determined, the occlusion device in the first shape of the interlaced structure (10) being in a folded condition and in the second shape of the interlaced structure (10) being in an expanded condition. The aim of the invention is to provide an occlusion device which can be implanted in as gentle a manner possible for the patient. For this purpose, the threads of the interlaced structure (10) consist of a shape memory polymer composition so that the interlaced structure (10) is deformed under the effect of an external stimulus from a temporary shape to a permanent shape, the temporary shape being the first shape of the interlaced structure (10) and the permanent shape being the second shape of the interlaced structure (10).

Owner:OCCLUTECH GMBH

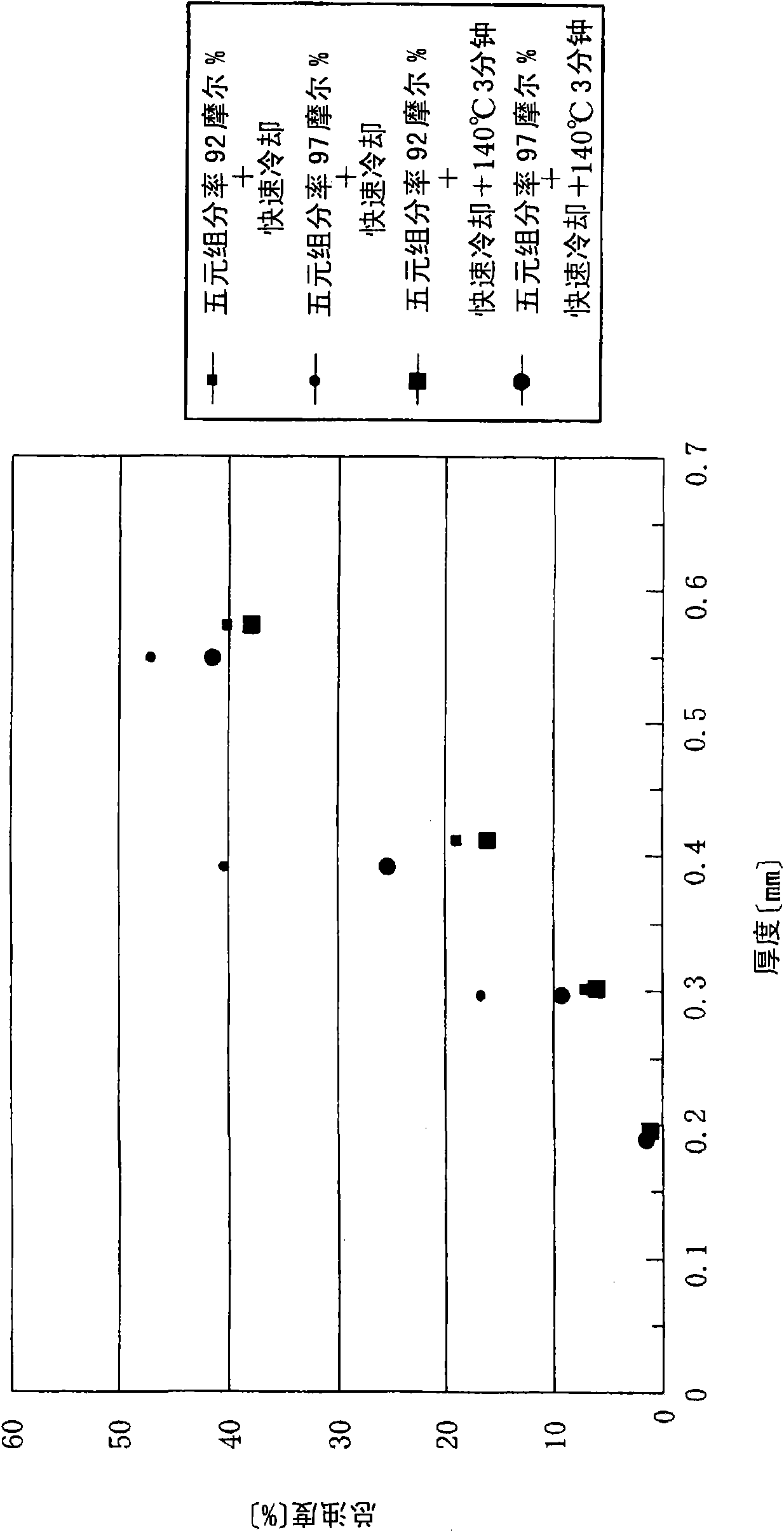

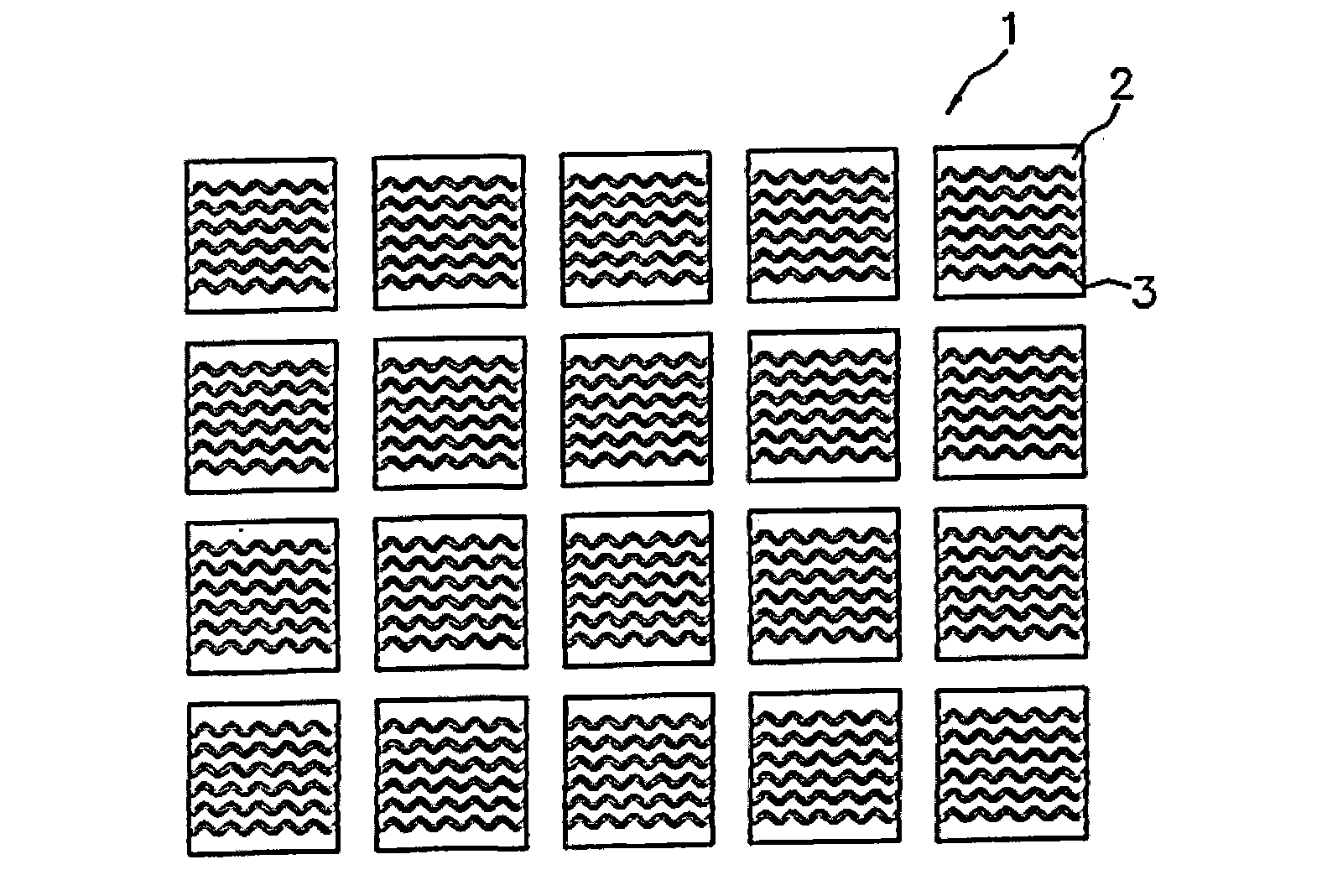

Polypropylene molded article, sheet-like polypropylene molded article, and method for production of polypropylene thermally molded article

ActiveCN101688005AImprove visual effectsFully rigidFlat articlesThin material handlingAmorphous phasePolypropylene

A molten polypropylene having such a stereoregularity that the isotactic pentad fraction is 95% by mole or more is allowed to flow. The molten polypropylene is cooled to a temperature of -200 to 50 DEG C (inclusive), and is maintained at that temperature for 0.1 to 100 seconds (inclusive), thereby producing a rapidly cooled polypropylene high-order structure mainly composed of a mesophase or monoclinic domain having a size of 100 nm or smaller and an amorphous phase. The rapidly cooled polypropylene high-order structure is heated to a temperature that falls within a temperature range in which endothermic transfer occurs and that is equal to orlower than the melting temperature of the polypropylene.

Owner:IDEMITSU UNITECH CO LTD

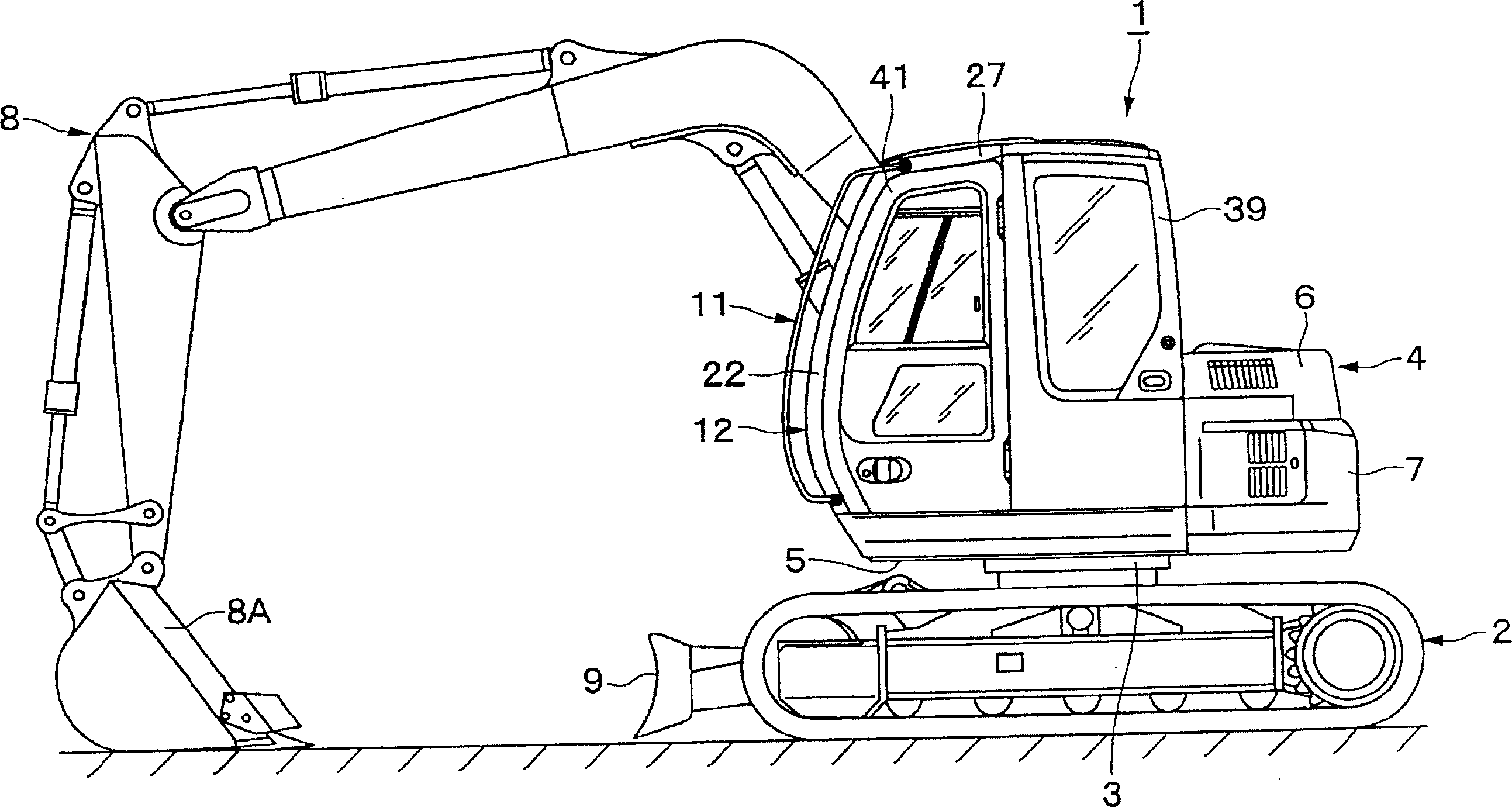

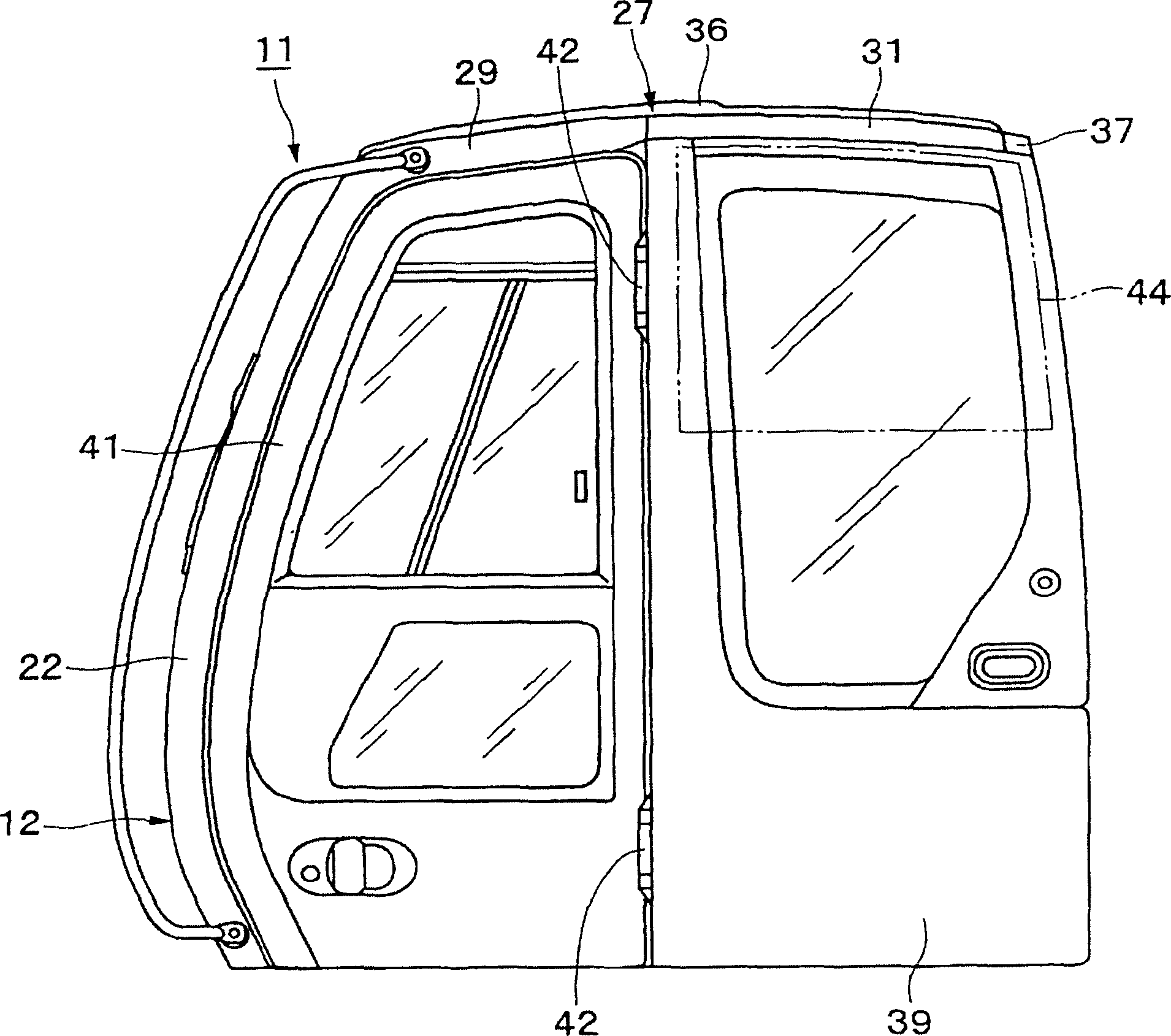

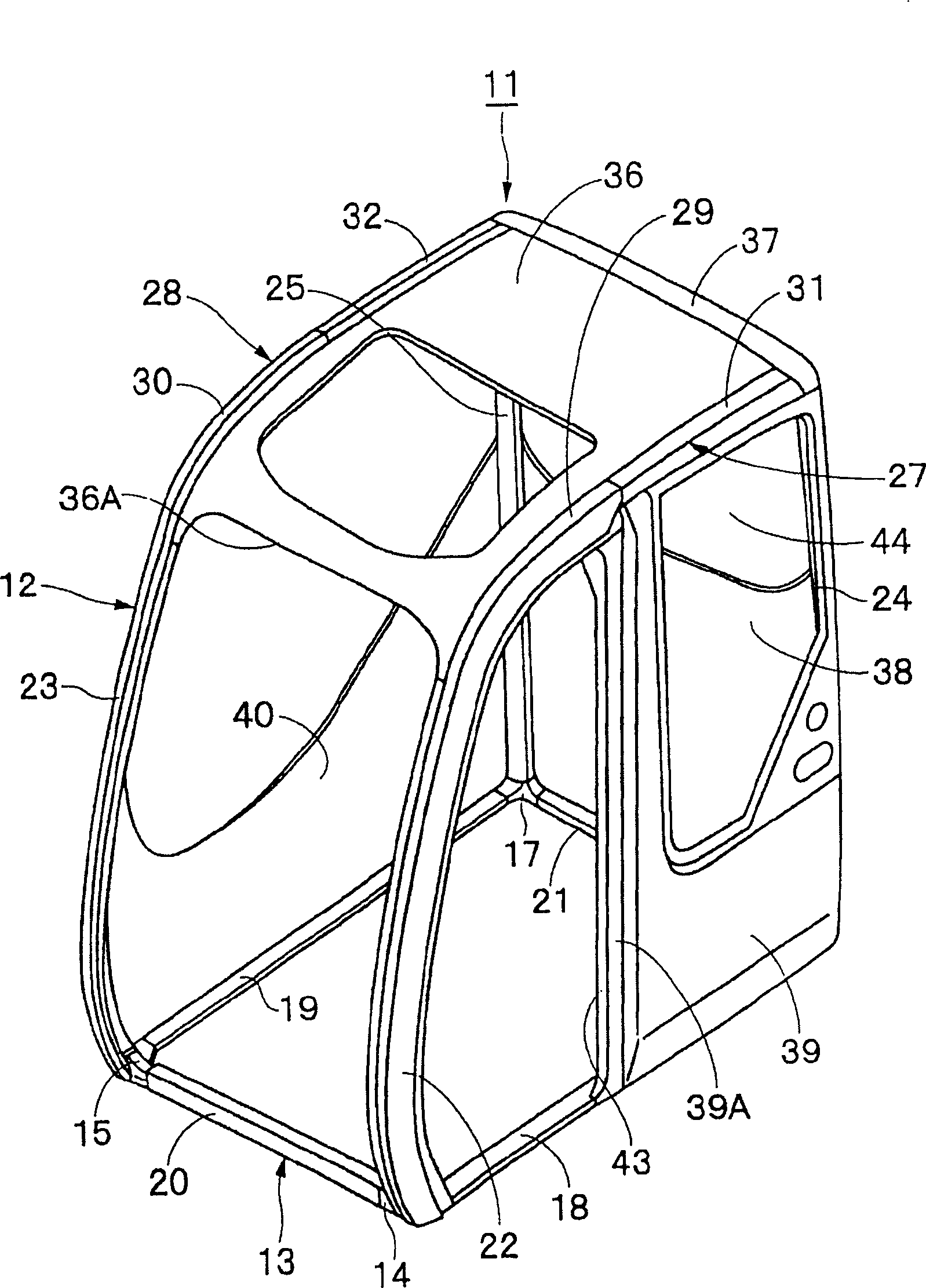

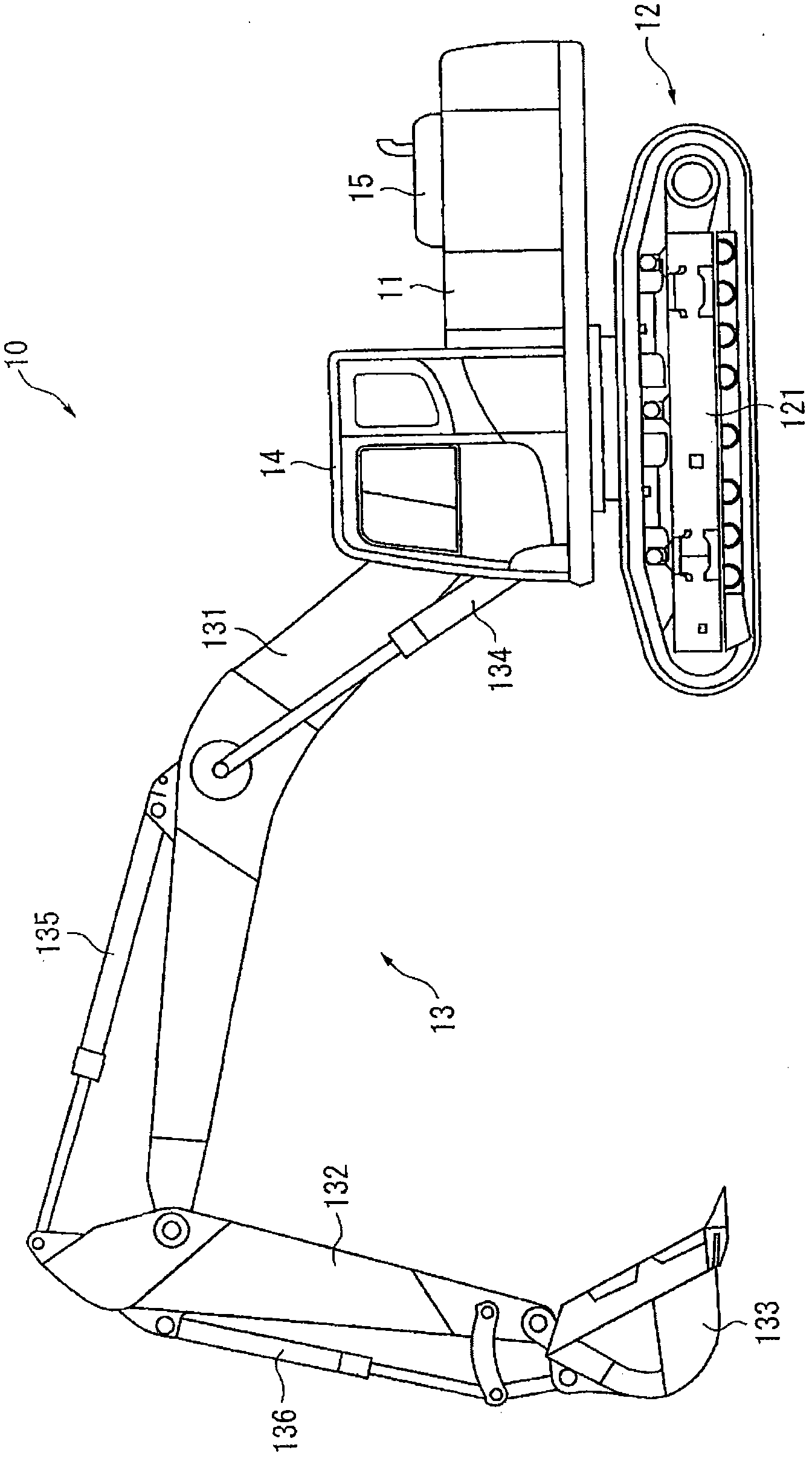

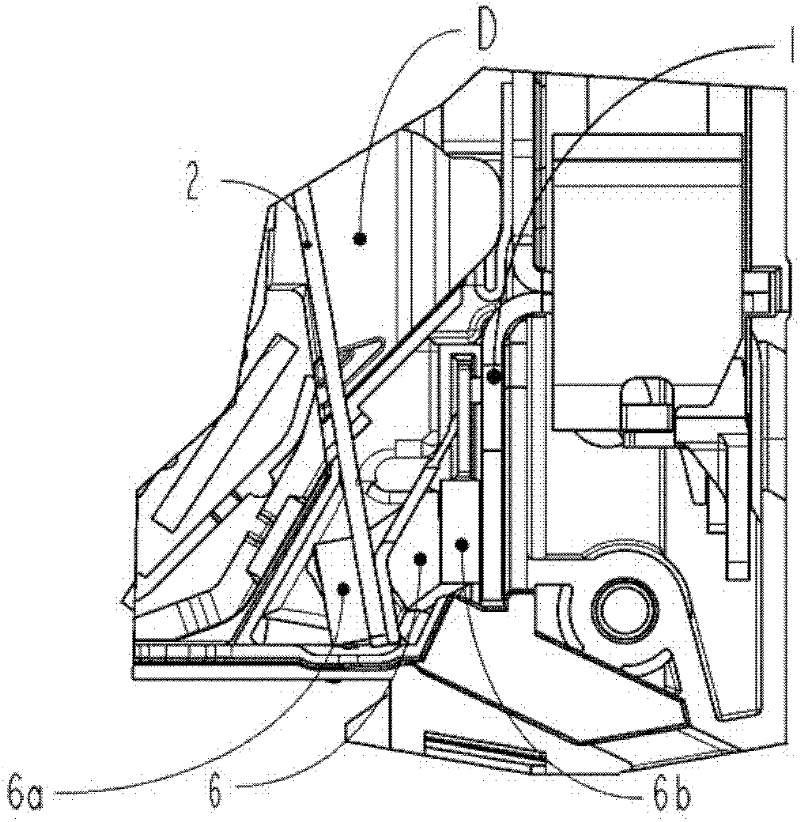

Cab of construction machinery

ActiveCN1712645AImprove rigidityFull strengthSoil-shifting machines/dredgersVehiclesMechanical engineeringBuilding construction

PROBLEM TO BE SOLVED: To protect an operator inside a cab with a sufficient rigidity by suppressing the deformation of a rear space in the cab when a vehicle is turned over. SOLUTION: Left and right upper pillars 27 and 28 positioned on the ceiling side of a cab frame 12 are formed of left and right upper extension members 29 and 30 installed extendedly from the upper end side to the rear side of the left and right front pillars 22 and 23 and left and right connection members 31 and 32 connecting the rear end sides of the upper extension members 29 and 30 to the upper end sides of left and right rear pillars 24 and 25. Left and right connection members 31 and 32 are formed in solid beam members by a casting or forging means. Also, beam members 33 and 34 apart a distance in the longitudinal direction and extending in the lateral direction and having both ends joined to the connection members 31 and 32 by welding are installed between the connection members 31 and 32. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:NIHON KENKI CO LTD

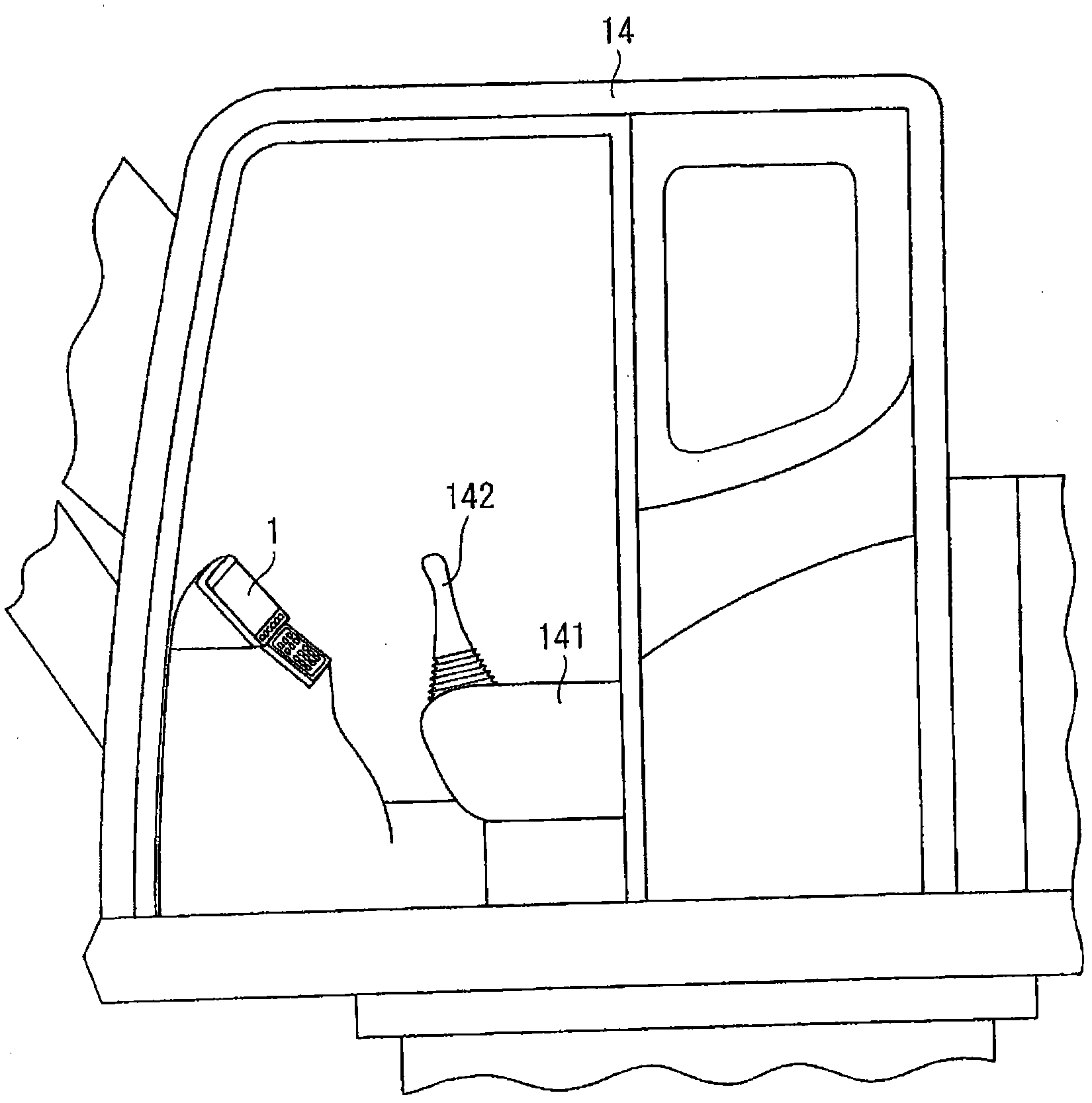

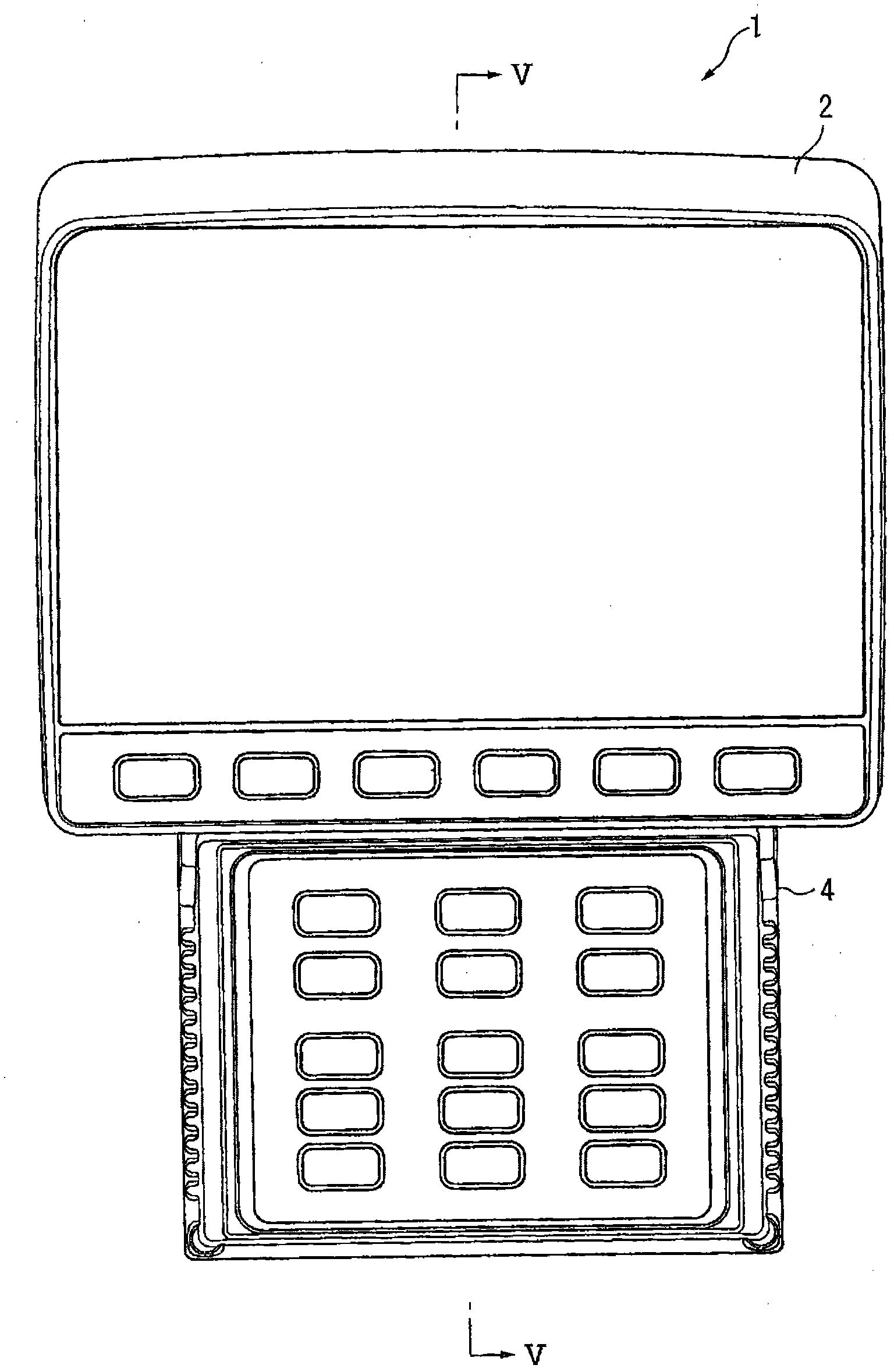

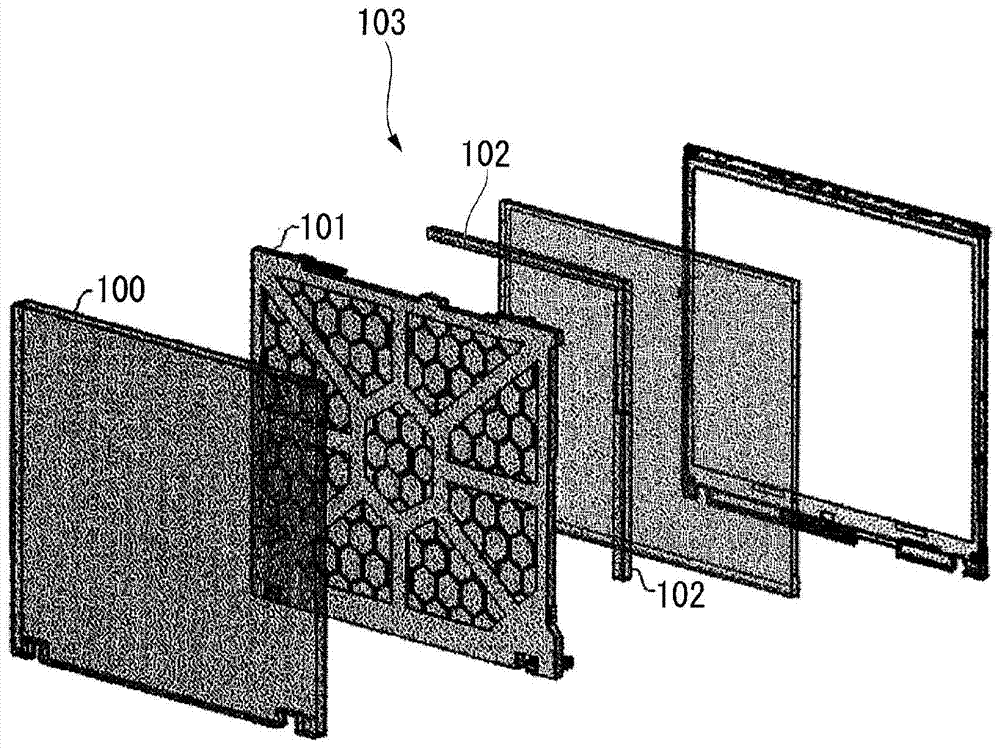

Display device for vehicle

ActiveCN102079275APrevent inflowAvoid condensationSoil-shifting machines/dredgersVehicle componentsDisplay deviceEngineering

The invention provides a display device (1) for a vehicle, which comprises a display (22), a first substrate (26) for be displayed on the display (22), a frame (5) for accommodating the display (22) and the first substrate (26) and a first separation part (42) for separating the internal of the frame (5).The display (22) side inside the frame (5) is set to be a first closed space (S1) and the first closed space (S1) is internally equipped with the first substrate (26).The frame (5) is equipped with a vent hole for communicating the inner space except the first closed space (S1) with the outside.

Owner:KOMATSU LTD

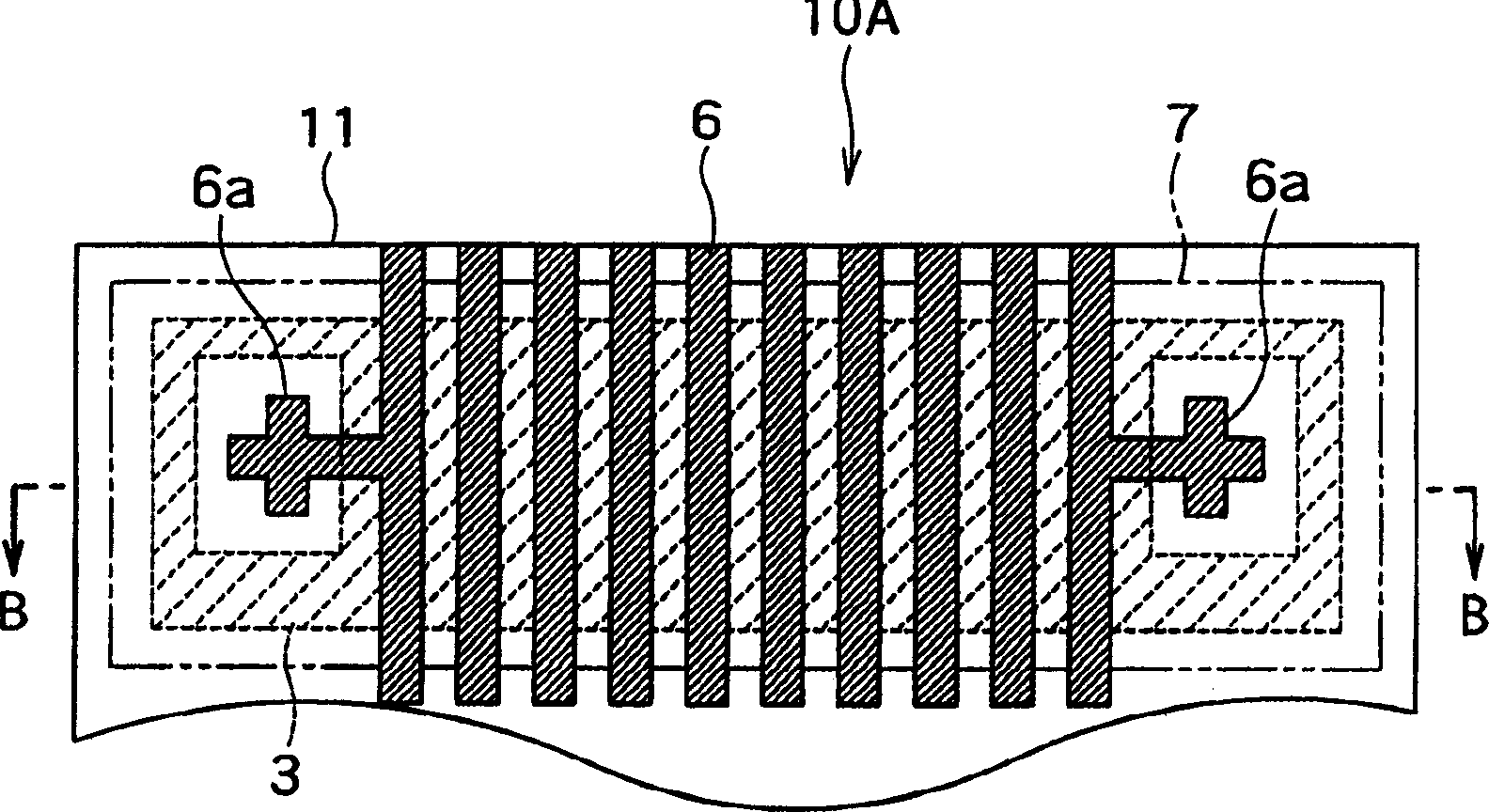

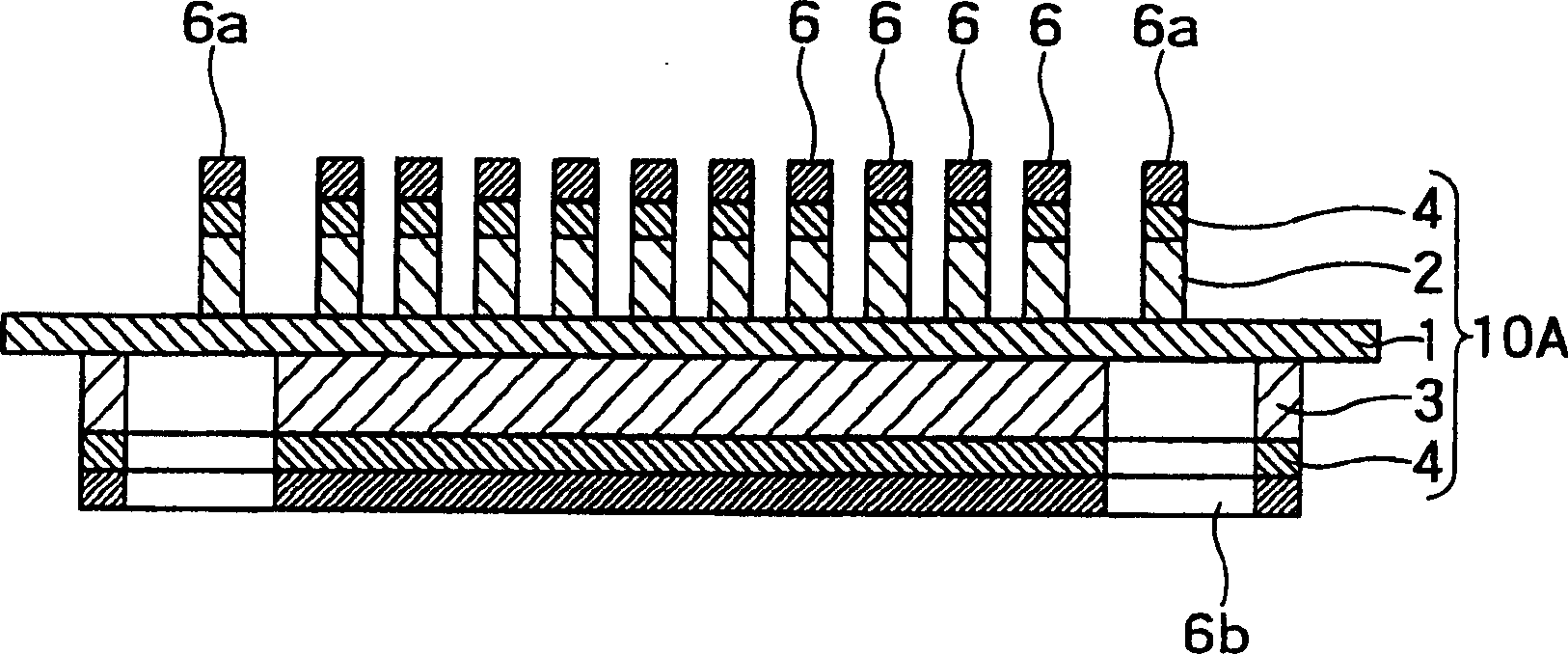

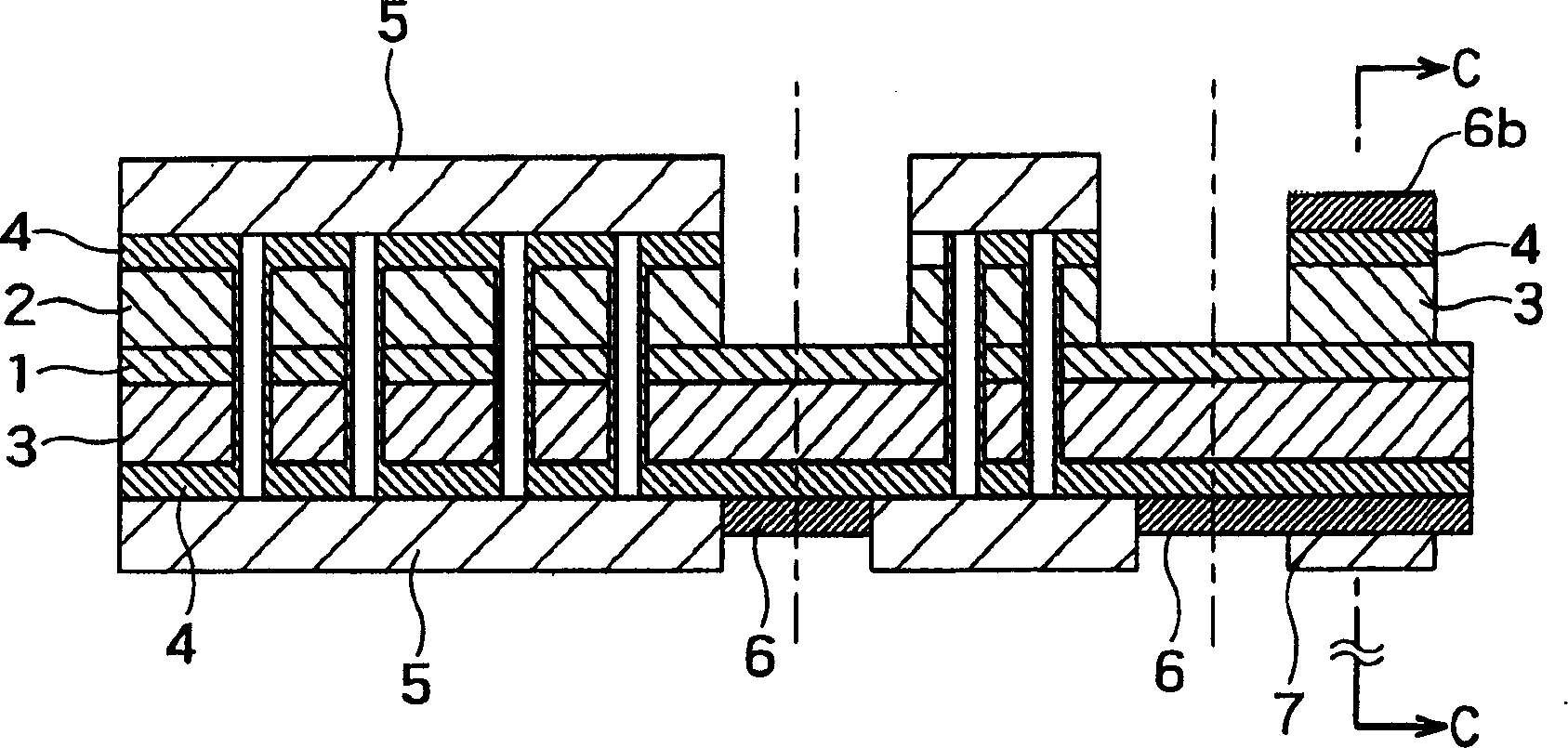

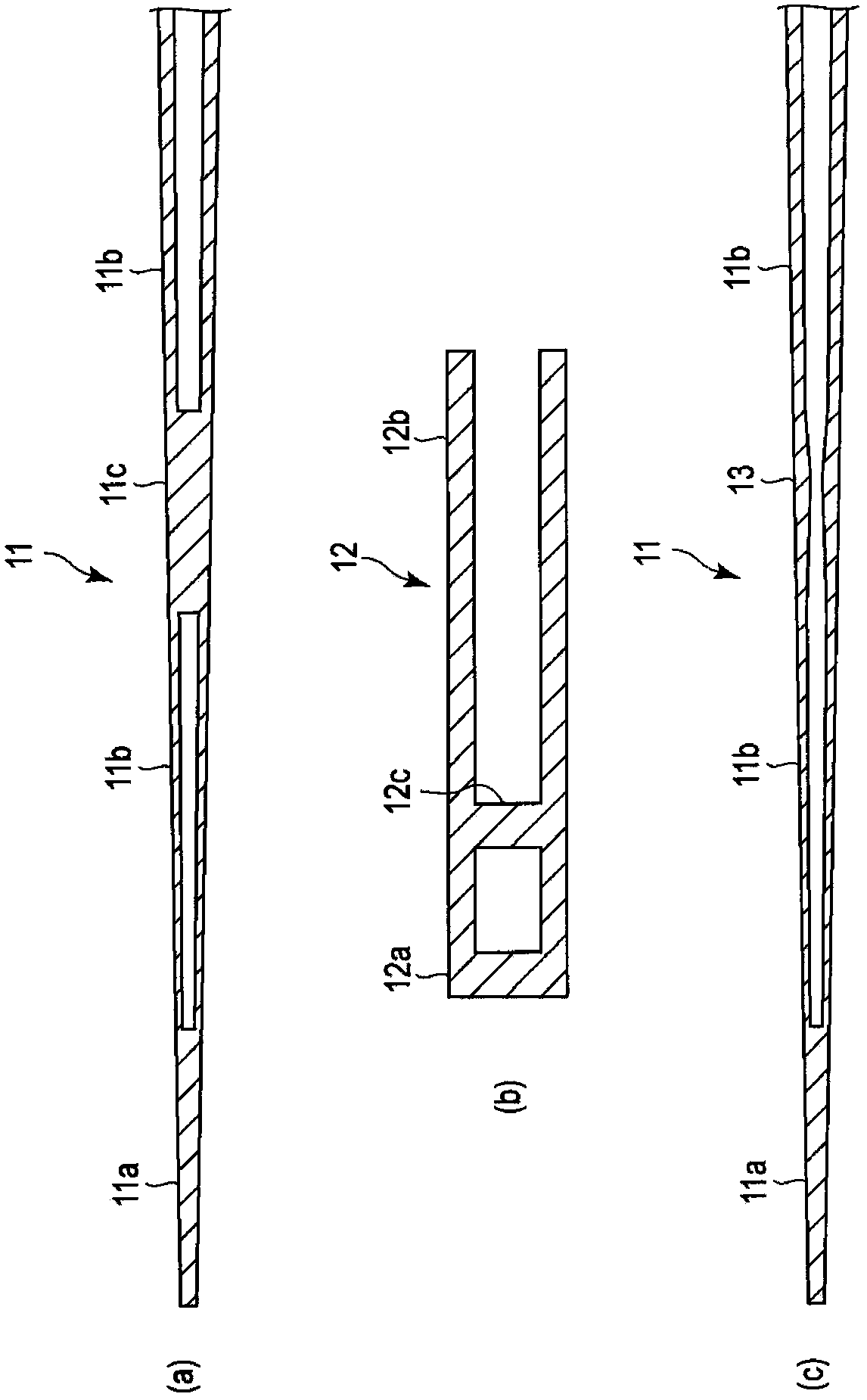

Flexible circuit substrate

InactiveCN1722930AWith transparencyFully rigidPrinted circuit assemblingSemiconductor/solid-state device manufacturingFlexible circuitsHardness

To provide a flexible circuit board that has hardness not to cause deflection or waving and has excellent workability in connecting to an object equipment or object board. A terminal for connecting to an object equipment or object board through an anisotropic conductive resin layer as well as a wiring layer having a terminal region at its end where a mark representing the position of the terminalis provided are formed on at least one surface of an insulating layer of the flexible circuit board. The flexible circuit board 10A comprises a solid wiring layer 6b provided with an opening for seeing through the mark at the position out of the inside terminal region, with the outer edge of the anisotropic conductive resin layer inside the outer edge of the circuit board and the terminal region as an edge, corresponding to the terminal region of the surface opposite to the surface where the wiring layer corresponding to the terminal region is provided. The insulating layer 1 has transparencyto see through the solid wiring layer.

Owner:NIPPON MEKTRON LTD

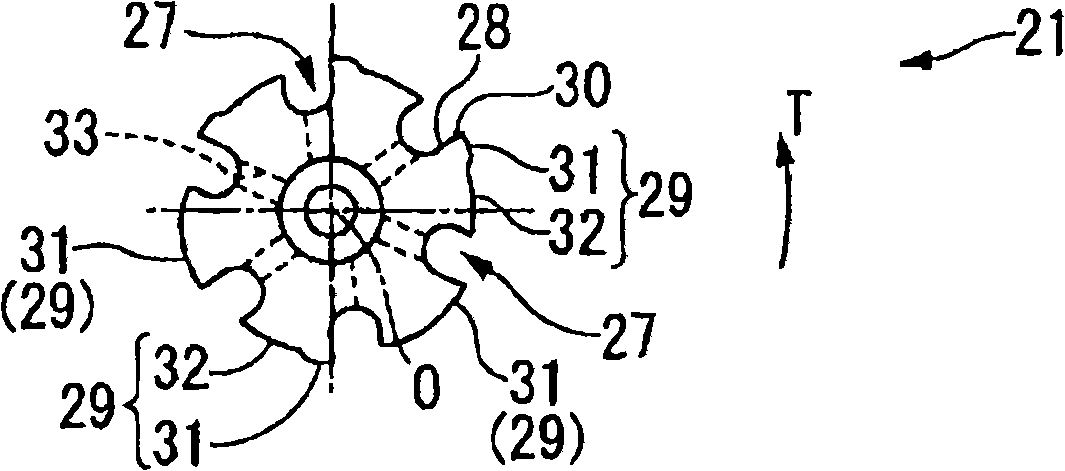

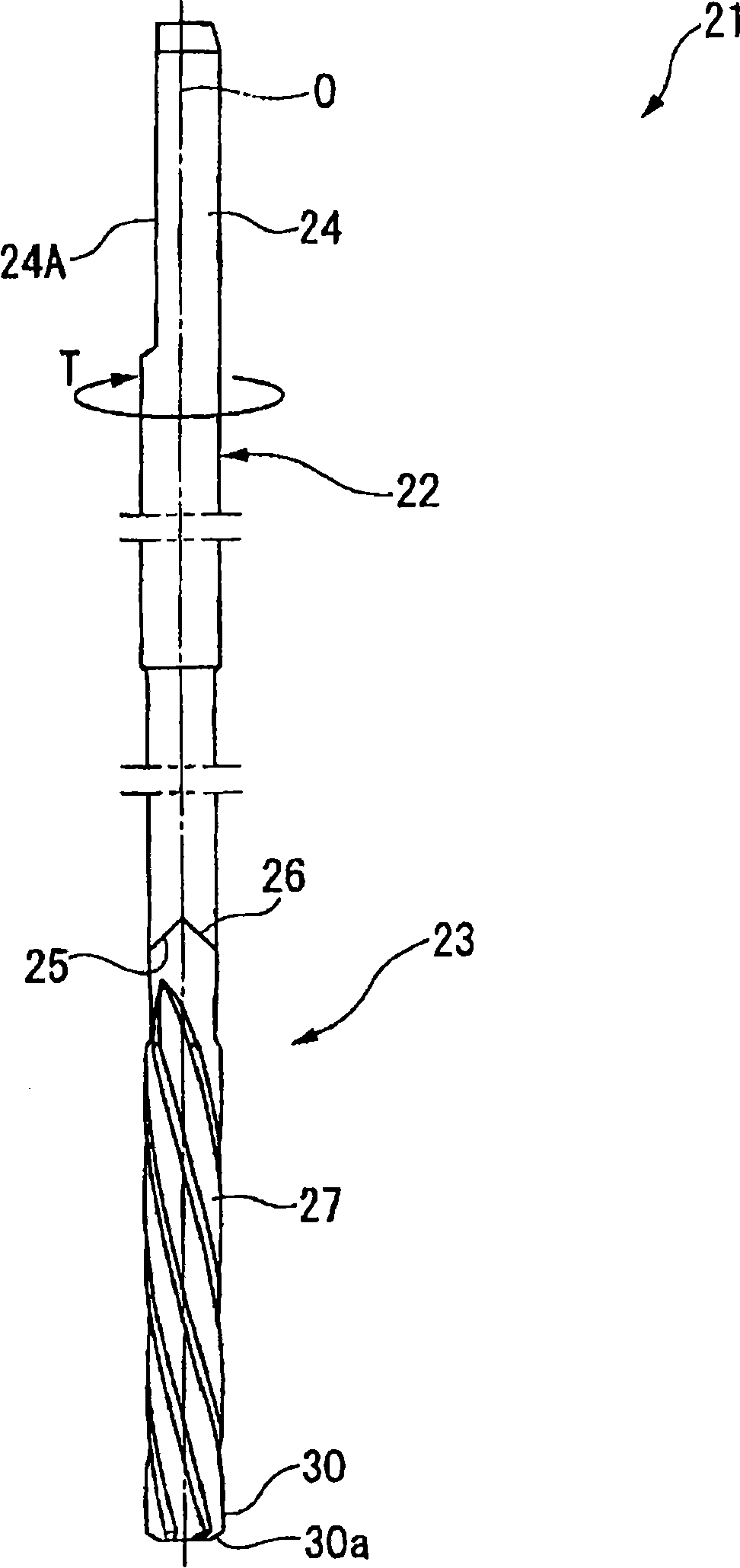

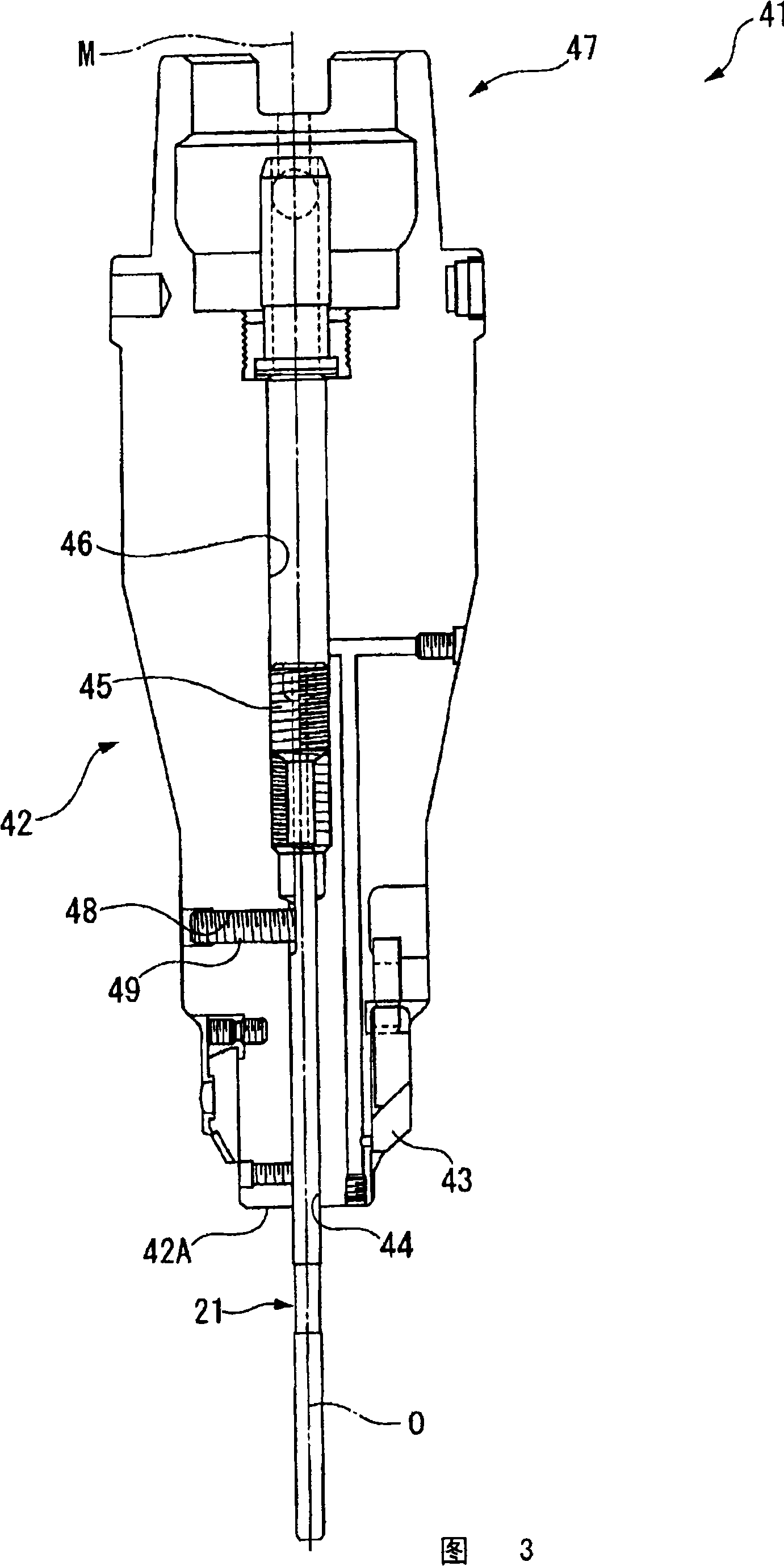

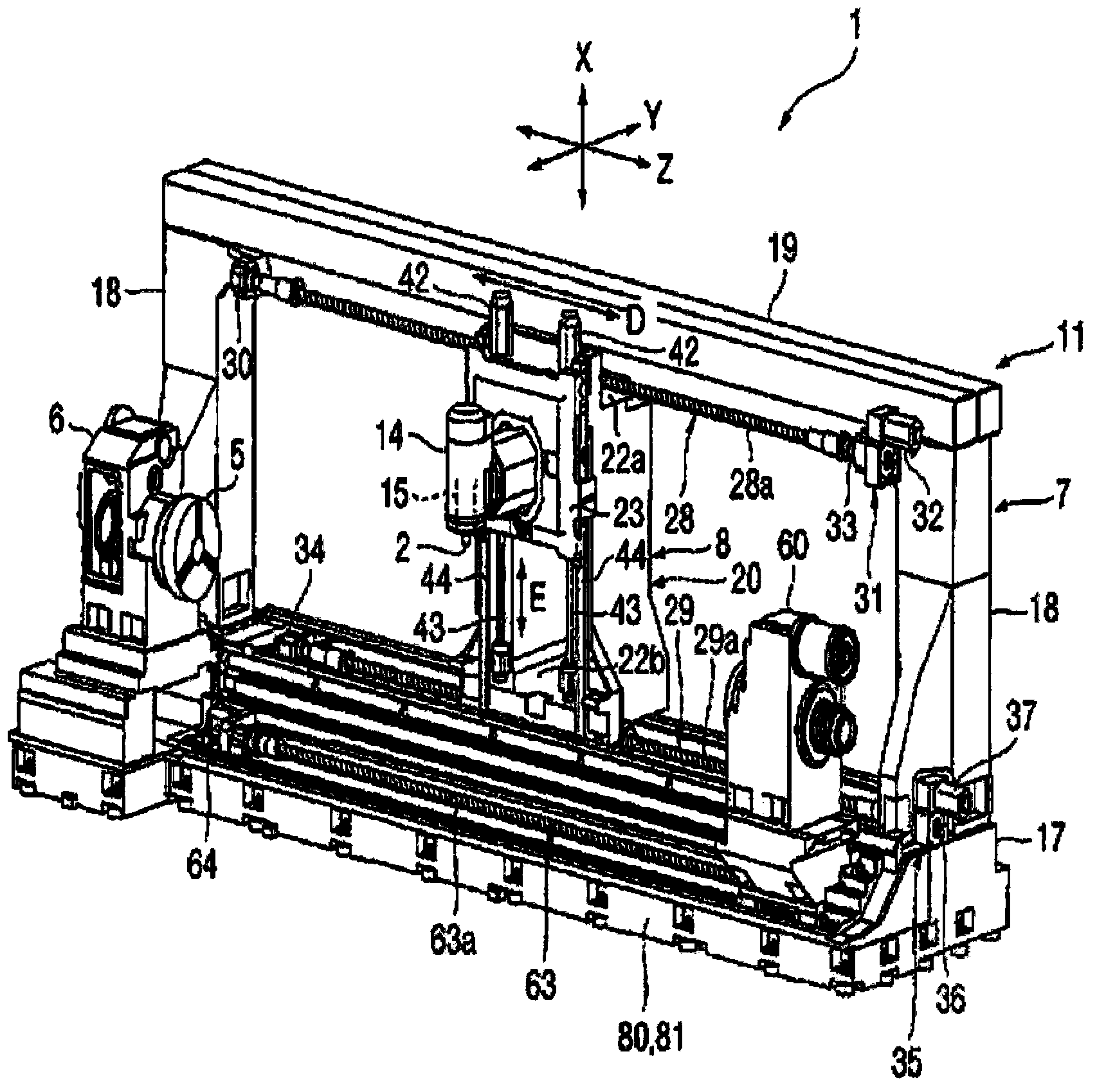

Boring tool and method of boring pilot hole

A boring tool capable of accurately forming a bored hole by securing the rigidity of a reamer to prevent turnout of the reamer at high speeds and enabling an increase in life by suppressing the breakage thereof by cutting resistance. The boring tool (21) is inserted into a pilot hole formed in a workpiece beforehand to cut the inner wall surface of the pilot hole. The boring tool comprises a shank part rotated about an axis (O), an edge part with a cutting edge (30) at the tip of the shank part, and a chip discharging groove (27) formed in the outer peripheral part of the edge part and extending from the tip side to the rear end side. The cutting edge (30) is formed at a crossed ridge part between the wall surface (28) of the chip discharging grove (27) facing forward in the tool rotating direction (T) and the outer peripheral surface (29) of the edge part. The boring tool is characterized in that the cross-section of the chip discharging groove (27) vertical to the axis (O) is formed in a U-shape.

Owner:MITSUBISHI MATERIALS CORP

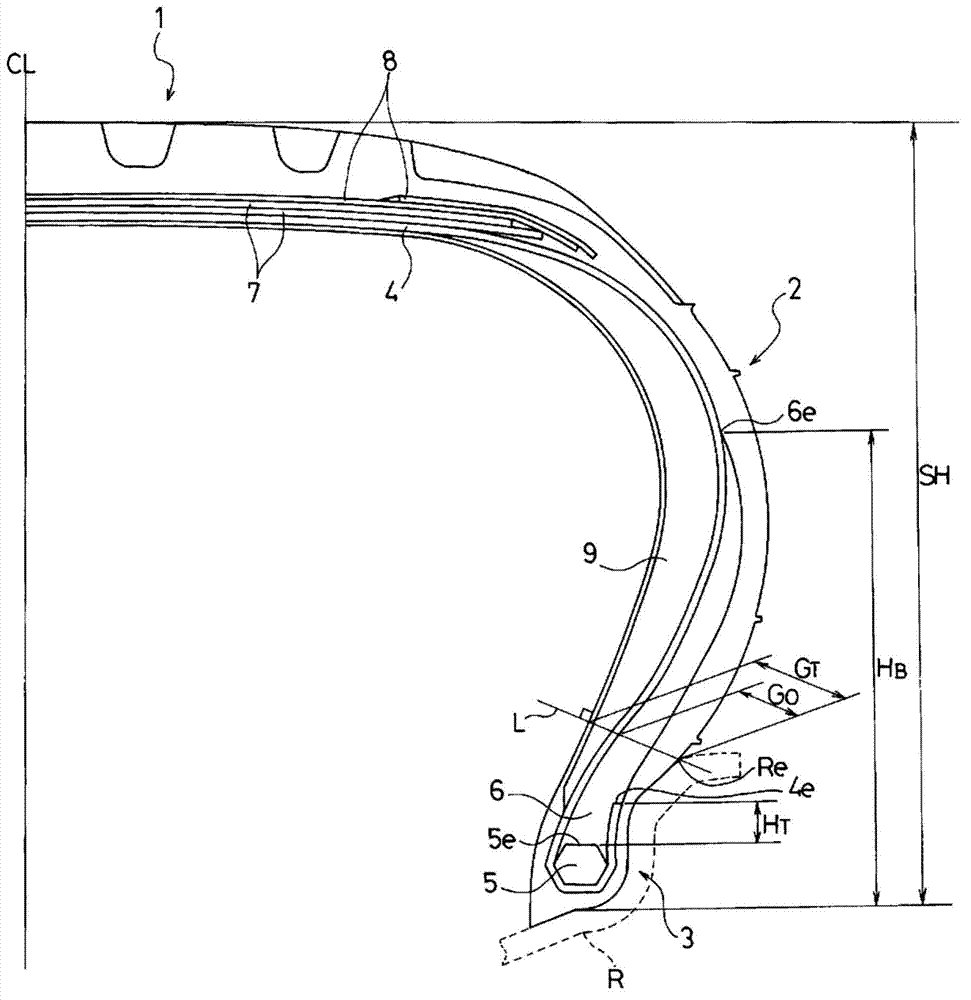

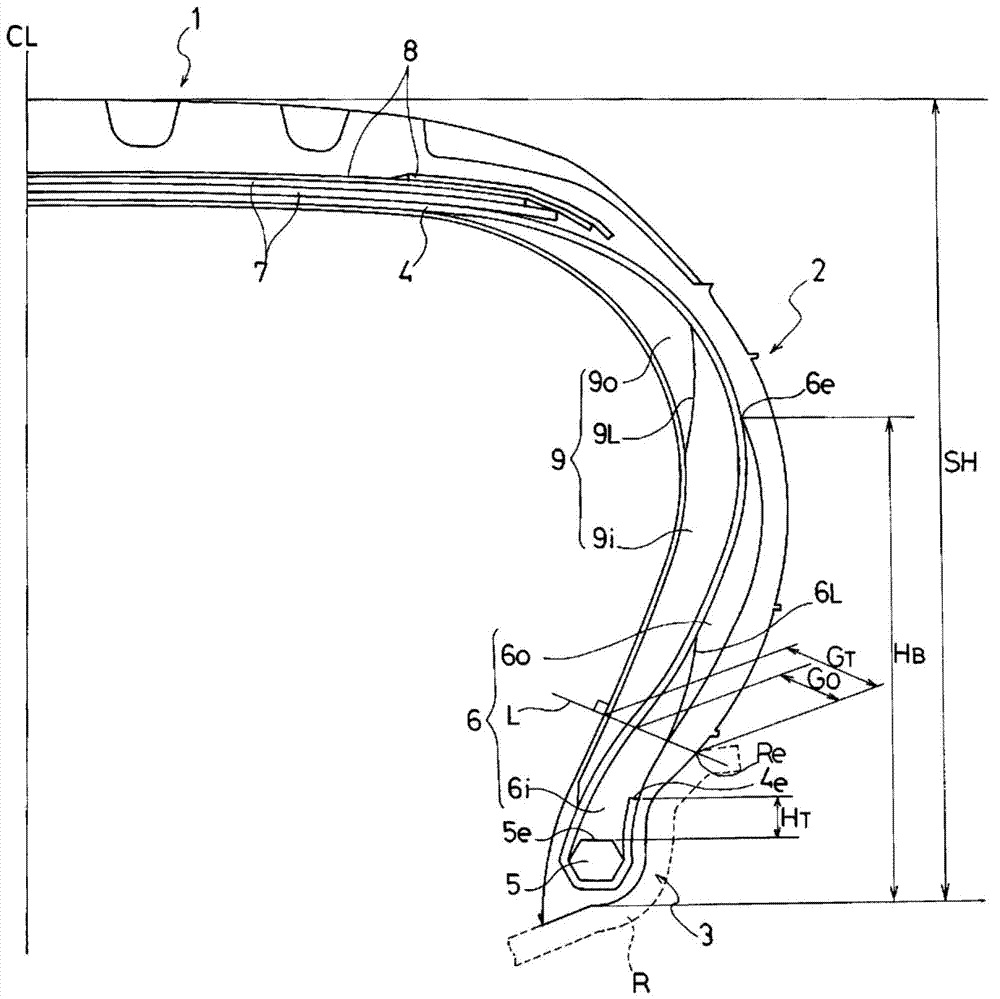

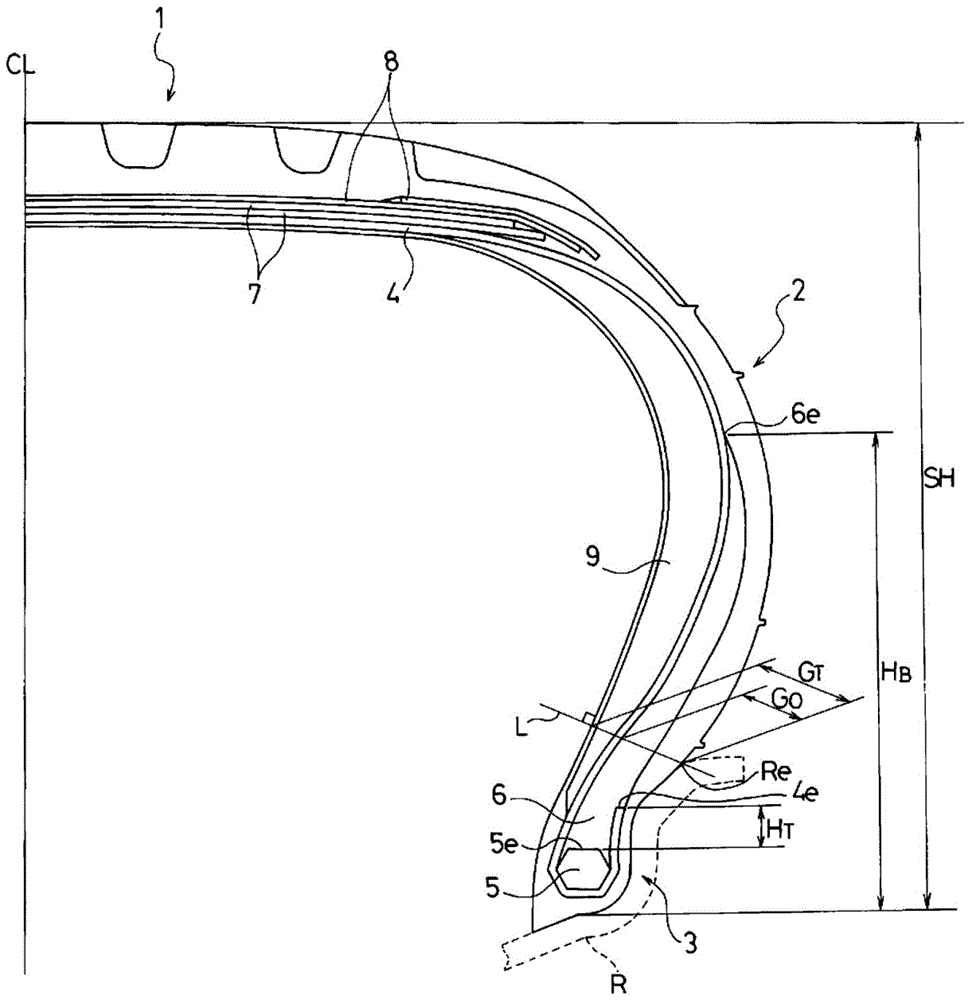

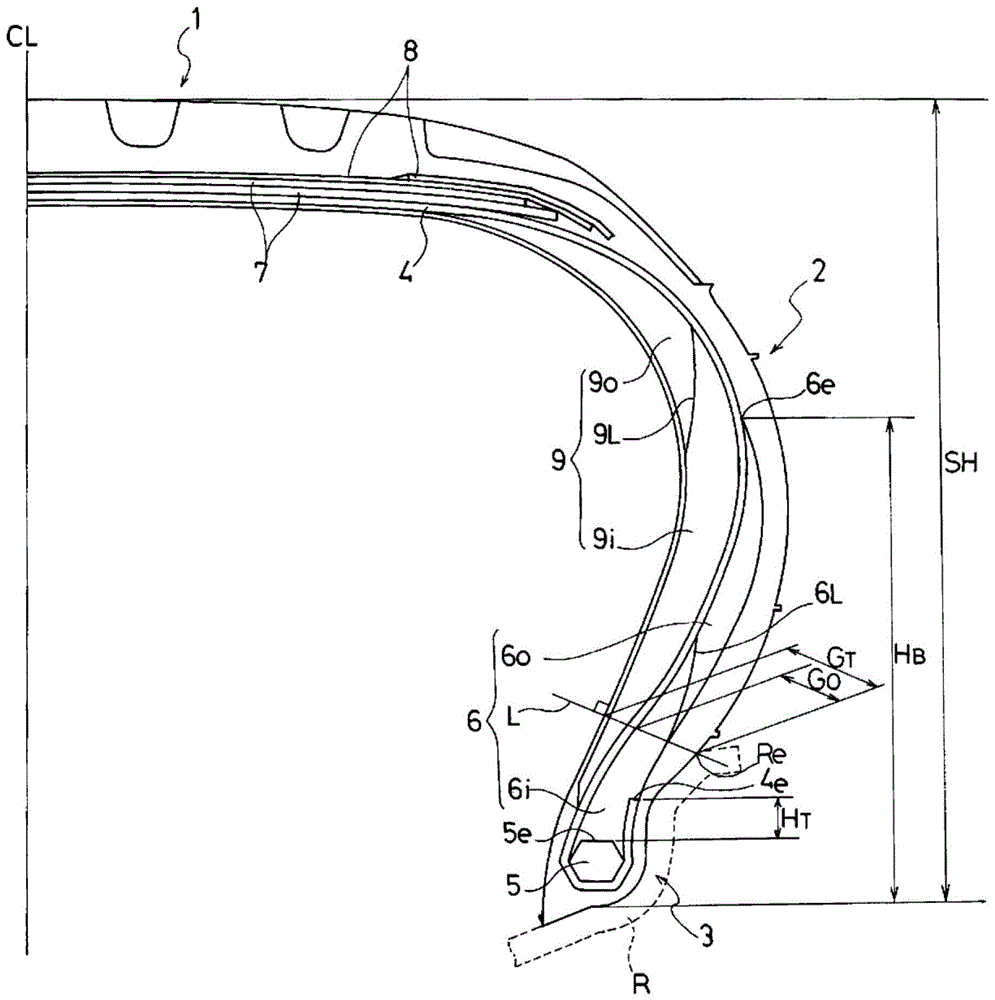

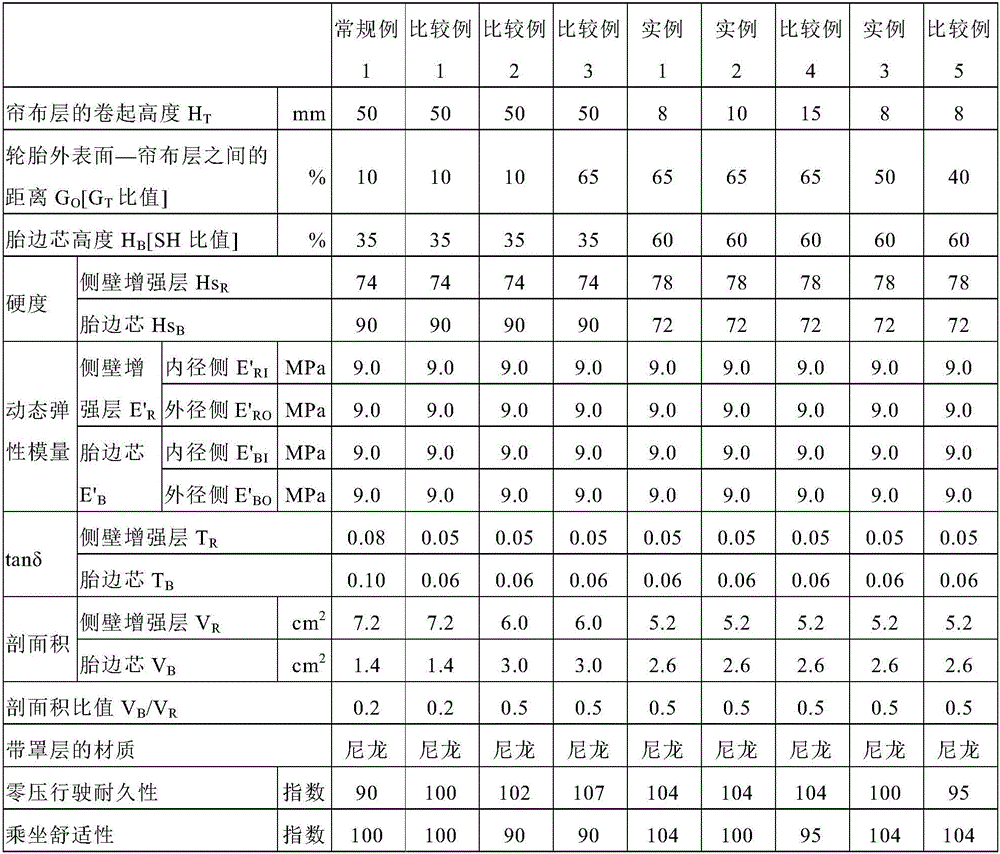

Pneumatic tire

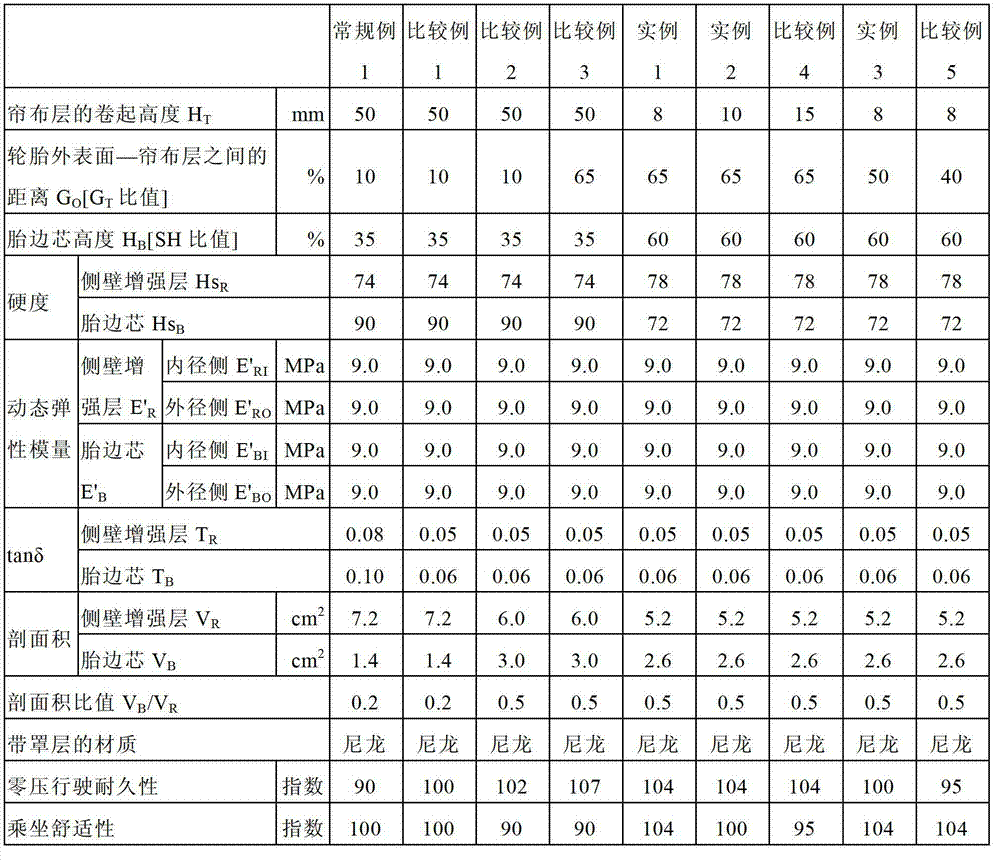

InactiveCN103317971AReduce rigidityGuaranteed rigidityTyre beadsTyre sidewallsEngineeringDynamic elastic modulus

In a pneumatic tire, a height from a turned-up edge of a carcass layer (4) is not more than 10 mm, a distance GO from a tire outer surface to the carcass layer (4) is not less than 50% of the total gauge, a height HB of the bead filler (6) is from 50% to 80% of a tire cross-section height SH, a cross-sectional area ratio VB / VR of the bead filler (6) to a side reinforcing layer (9) is not less than 0.4 and not more than 0.6, a hardness HsB of the bead filler (6) is not less than 65 and not more than 80, and the hardness HsR of the side reinforcing layer (9) is not less than 75 and not more than 85, a size relationship between the hardness HsB and the hardness HsR is HsB<=HsR, a dynamic elastic modulus E'B is not less than 7.0 MPa and not more than 15.0 MPa, and a dynamic elastic modulus E'R is not less than 7.0 MPa and not more than 15.0 MPa, a value TB of tan delta is not more than 0.06, and a value TR of tan delta is not more than 0.05. The invention provides a pneumatic tire by which both riding comfort when regular traveling and run-flat durability can be achieved at high levels.

Owner:THE YOKOHAMA RUBBER CO LTD

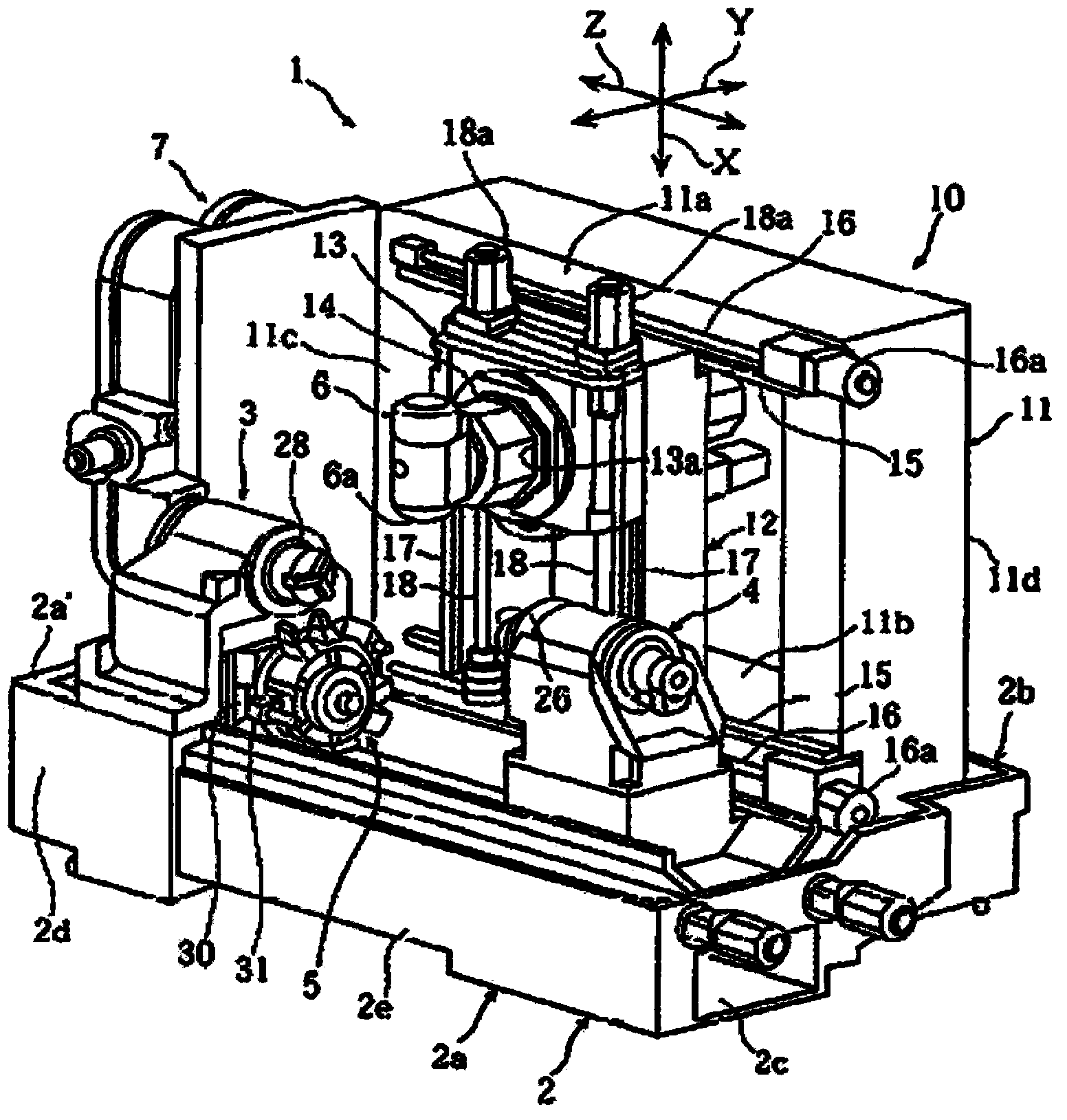

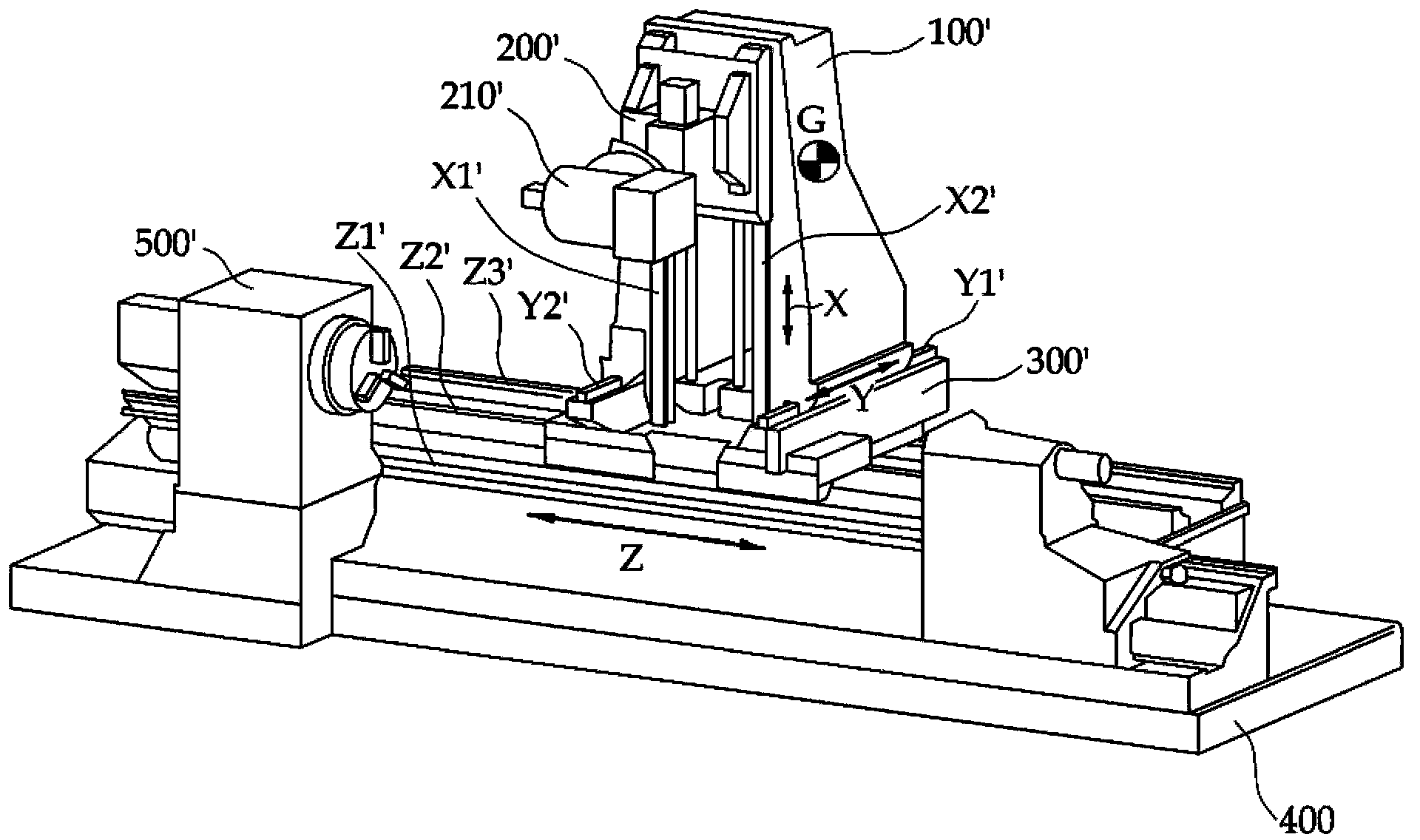

Highly rigid complex machine

ActiveCN103492120AReduce shakingImprove machining accuracyOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine tool

The present invention relates to a highly rigid complex machine having a structure in which parts constituting a shaft are disposed adjacent to the central portion of a column to reduce rolling and pitching, and a stage is disposed on a saddle to improve rigidity. The highly rigid complex machine includes: a bed (400) on the top surface of which Z-axis guide ways (Z1, Z2) are formed in a lengthwise direction; a saddle (300) on which Y-axis guide ways (Y1, Y2) are formed in the front and rear directions perpendicular to the lengthwise direction, the bottom surface of the saddle (300) having a shape corresponding to that of the top surface of the bed (400) so as to be conveyed in the lengthwise direction of the bed (400); a column (100) on which X-axis guide ways (X1, X2) are formed in the vertical direction perpendicular to the length direction, the column (100) being disposed on the saddle (300) so as to be conveyed in the forward and rearward directions along the Y-axis guide ways (Y1, Y2); and a working shaft (200) disposed at a front side of the column (100) so as to ascend or descend along the X-axis guide ways (X1, X2). The Y-axis guide ways (Y1, Y2) are disposed at positions that are spaced a predetermined distance apart from a lower end of the column (100) in the upward direction.

Owner:DN SOLUTIONS CO LTD

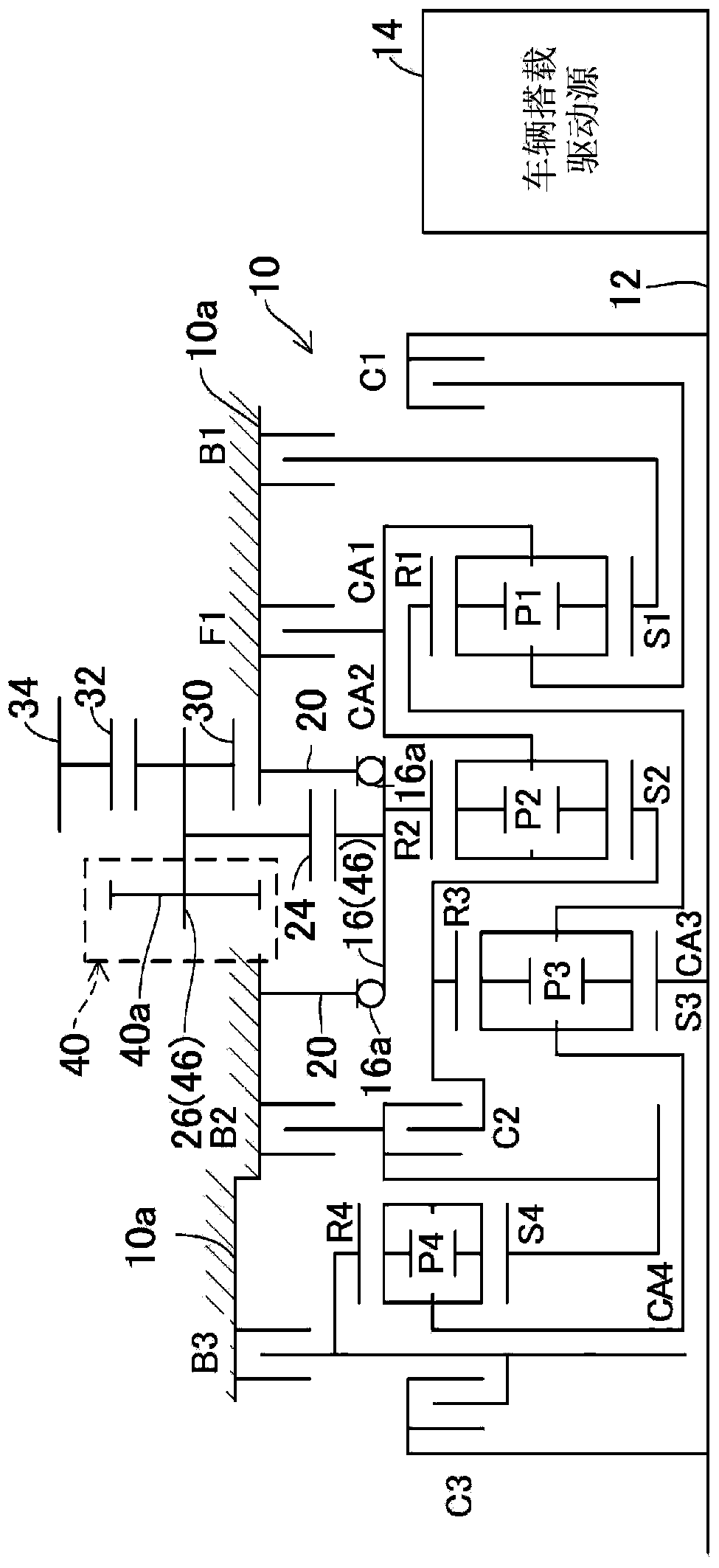

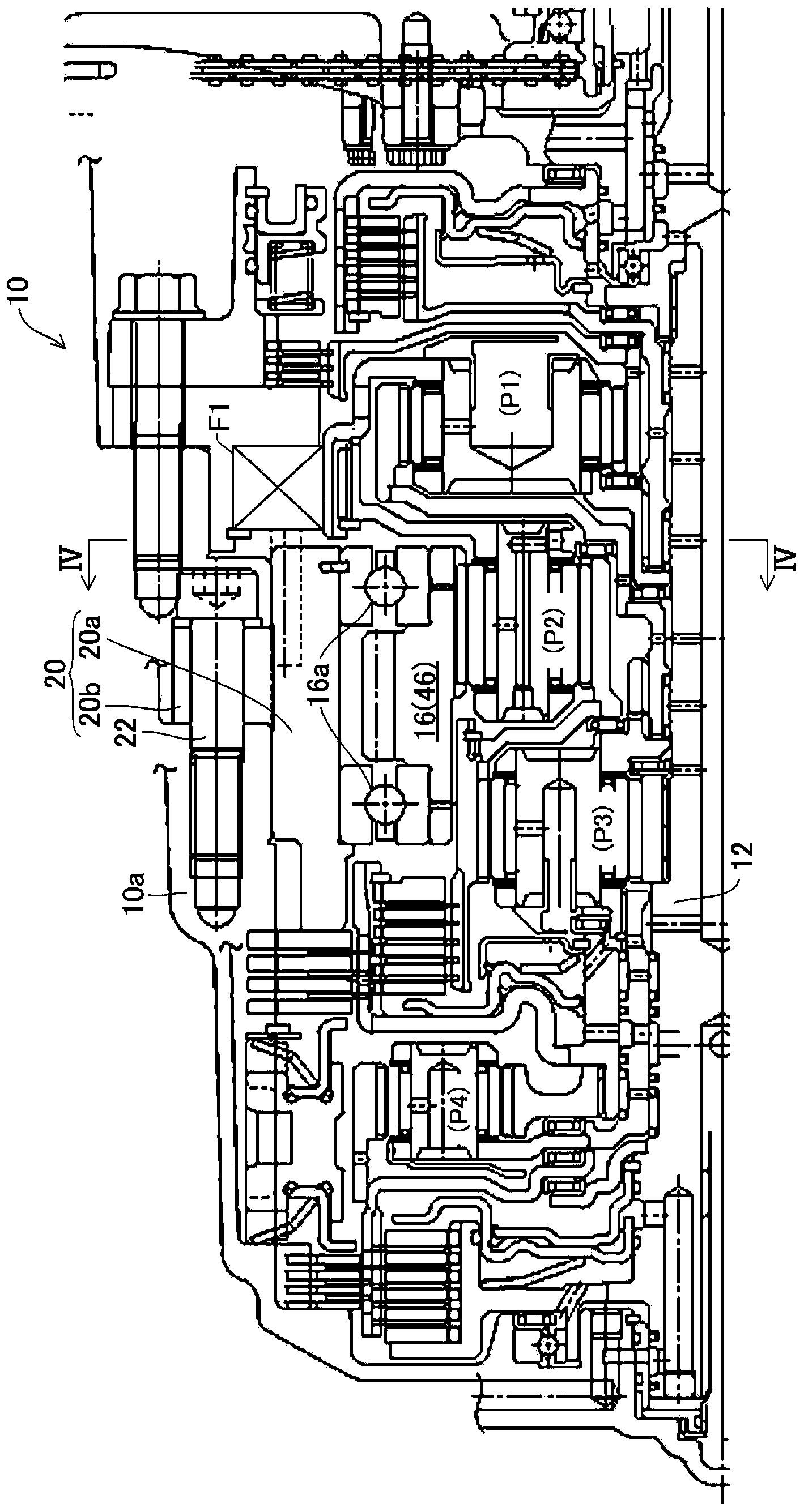

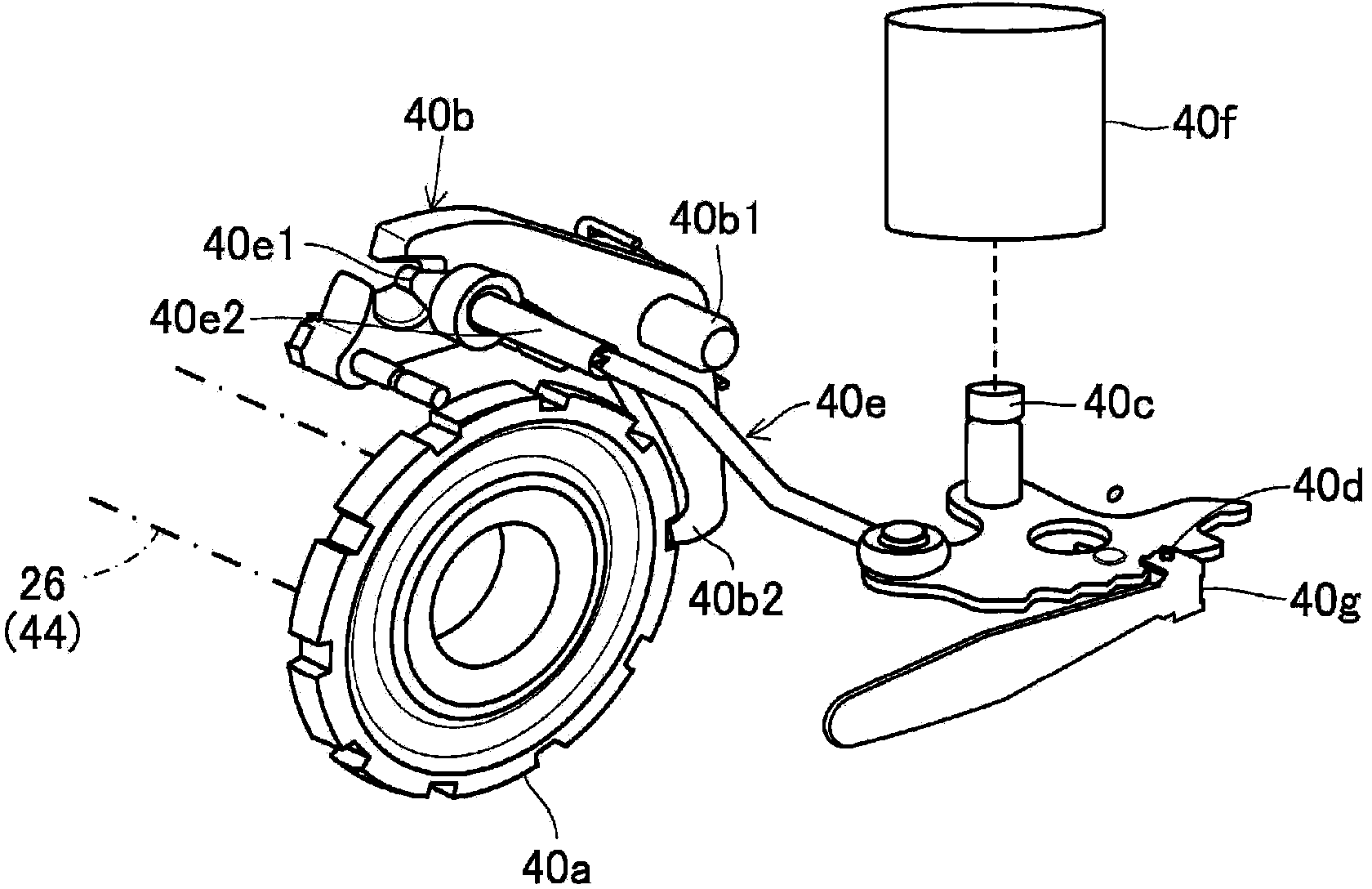

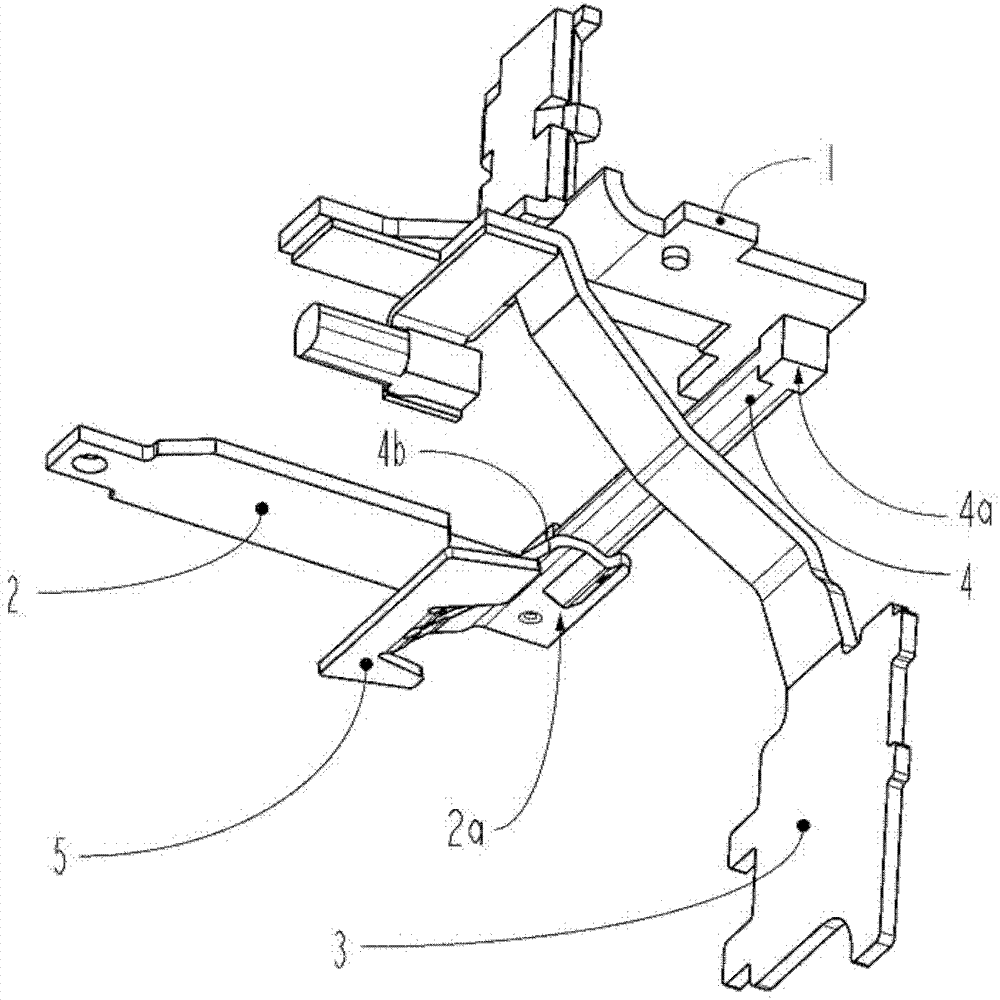

Parking mechanism for vehicle

ActiveCN104121361AImprove space efficiencyLow costBraking element arrangementsGearing controlRotational axisAutomatic transmission

A parking mechanism for a vehicle includes an automatic transmission, a parking gear, a parking pawl, and a parking-pawl turn member. The parking gear is fixed to a part formed by any of an output shaft of the automatic transmission and an intermediate member connected to the output shaft. The parking pawl is turnably attached to a turn shaft that is supported by a plate fastened to a transmission case by a first bolt and a second bolt. The parking-pawl turn member turns the parking pawl into engagement with the parking gear. An extending part formed by extending a support member that turnably supports the part of the automatic transmission is substituted for the plate. The extending part is fastened to the transmission case by the first bolt.

Owner:HONDA MOTOR CO LTD

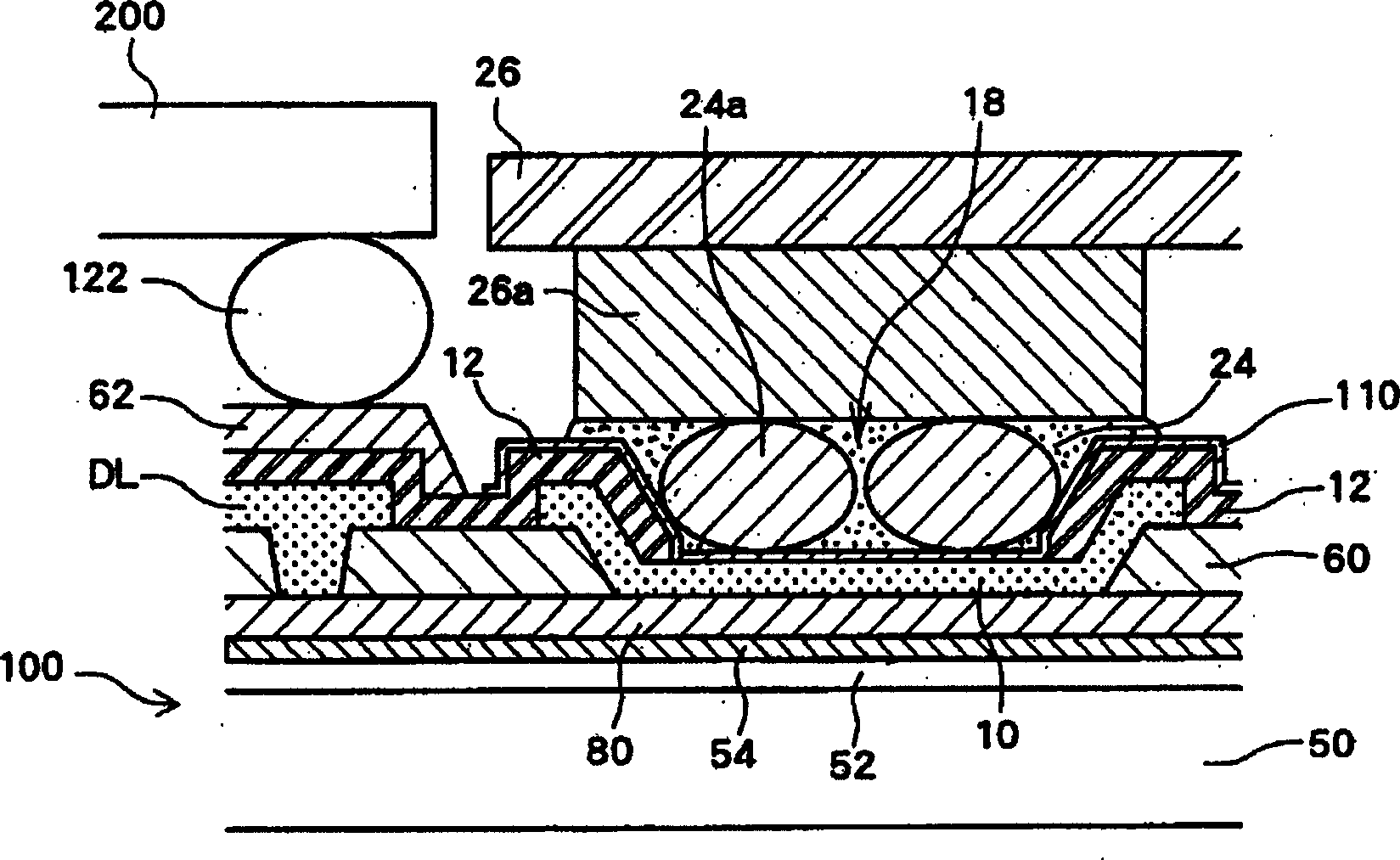

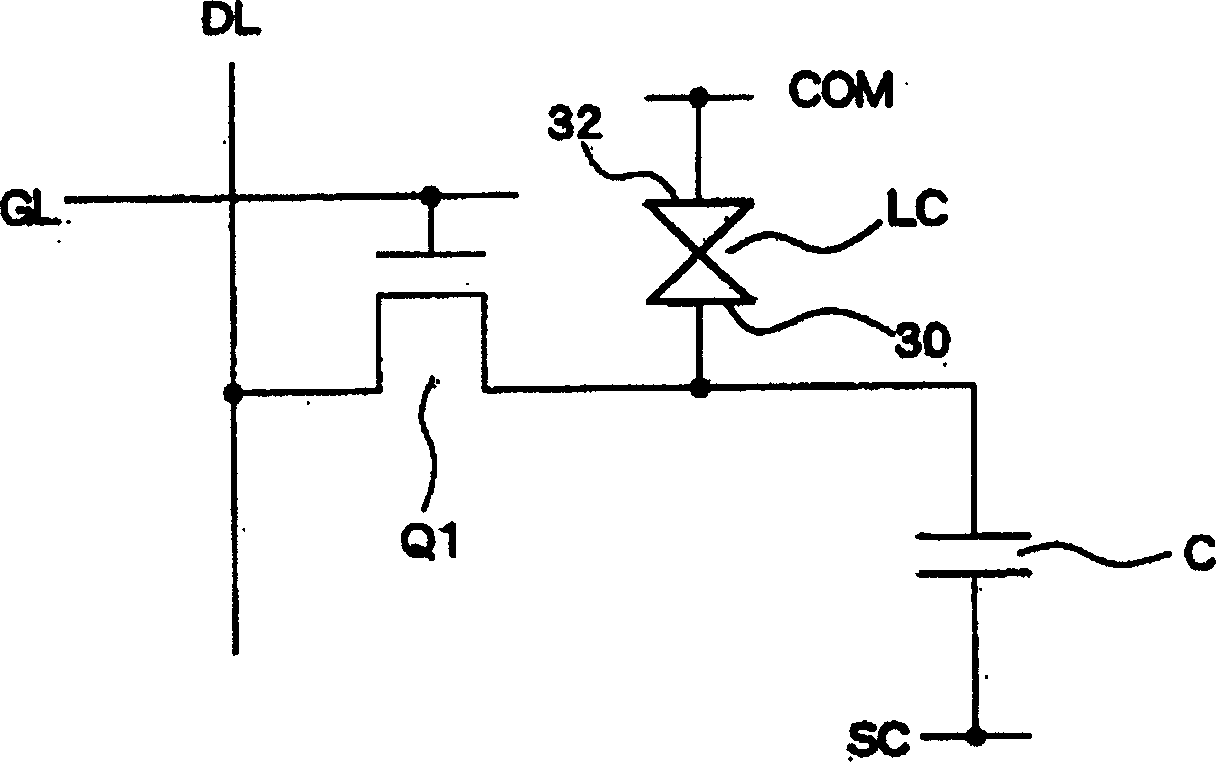

Display device and method for producing same

ActiveCN1854834AFully rigidReduce contact resistanceStatic indicating devicesSolid-state devicesDisplay deviceComputer science

A portion of a protective layer located above a connection portion is removed to expose the connection portion which is formed of the same material as used for a data line DL in this removed portion. Then, a transparent conductive layer made of ITO is further formed on these films. The transparent conductive layer and a bump are then connected via an AFC.

Owner:JAPAN DISPLAY INC

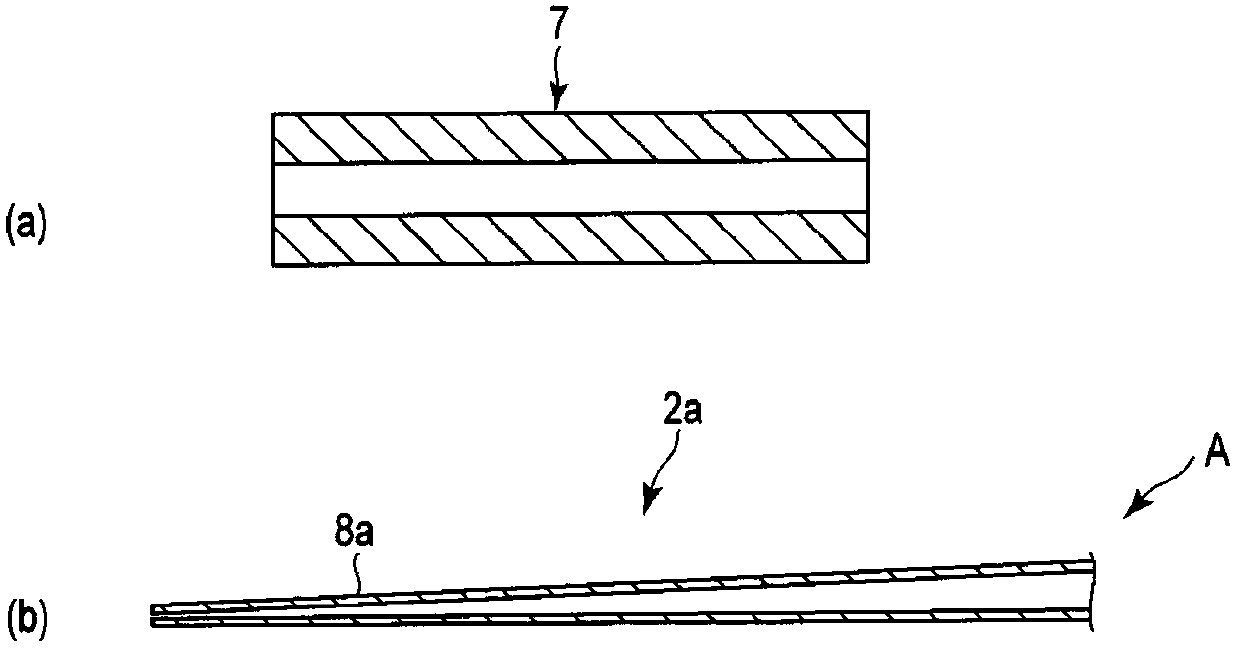

Molded fiber-reinforced composite material and manufacturing method therefor

InactiveCN104736332AFully rigidShielding materialsSynthetic resin layered productsFiber-reinforced composite

This sheet-shaped molded fiber-reinforced composite material is provided with the following: an EM-blocking prepreg comprising conductive fibers and a thermosetting matrix resin; an EM-transparent prepreg comprising non-conductive fibers and a thermosetting matrix resin; a first layer formed by joining the EM-blocking prepreg and the EM-transparent prepreg together, at a join line, in a direction perpendicular to the thickness direction of the molded fiber-reinforced composite material; a second layer that is formed on top of the first layer and contains the EM-transparent prepreg, disposed so as to cover at least part of the aforementioned join line; and an EM-transparent section, in the aforementioned thickness direction, that does not contain the EM-blocking prepreg.

Owner:MITSUBISHI CHEM CORP

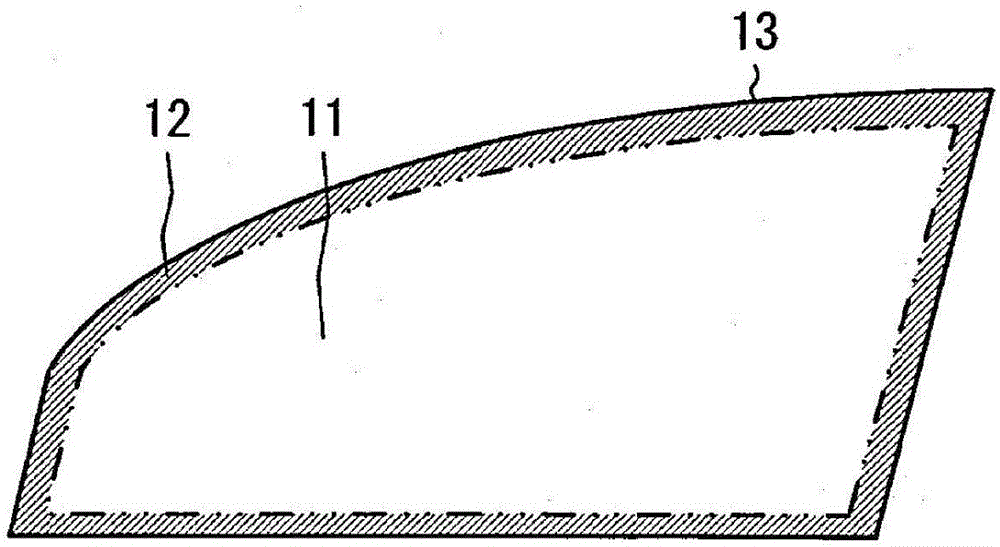

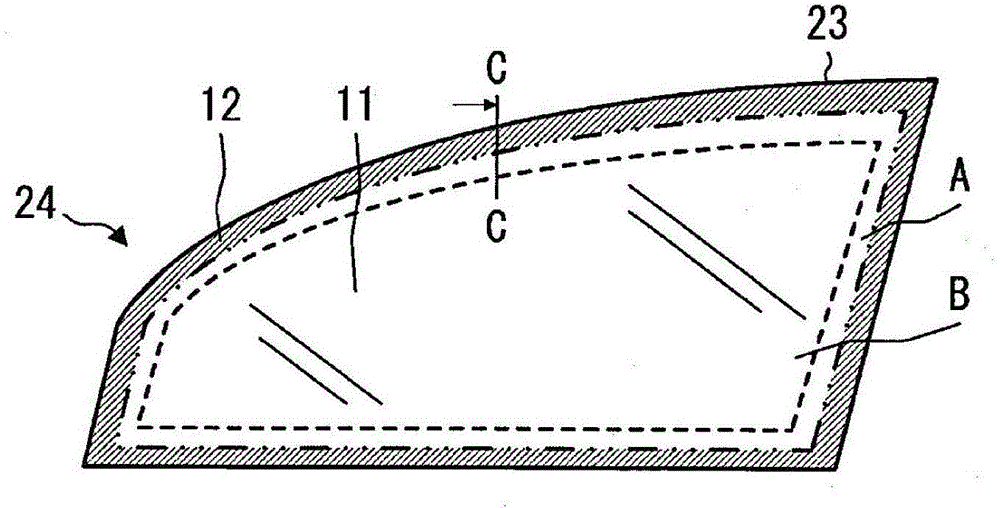

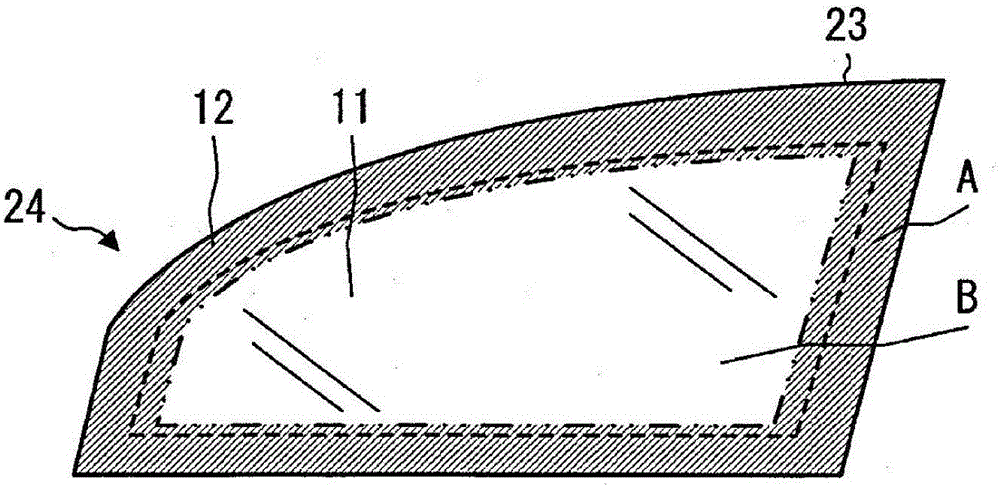

Laminated substrate for windows, framed laminated substrate for windows, vehicle comprising laminated substrate for windows, and intermediate layer structure for laminated substrate for windows

ActiveCN106103377AFully rigidAdequate sound insulationWindowsWindscreensInter layerMechanical engineering

A laminated substrate for windows, having a plurality of substrates laminated via an intermediate layer structure and having a peripheral edge area along the outer circumference of the laminated substrate for windows in the planar view and a center area on the inside of the peripheral edge area. The intermediate layer structure has a first area and a second area, in the planar view. The second area has an area ratio for the second area relative to the entire area of the laminated substrate for windows, in the planar view, that is at least (-74.87x + 204.47)% when 1.40 <= x <= 2.72 and at least (-0.0067x + 0.87)% when x> 2.72, when x is a value obtained by dividing the second area shear modulus relative to static force by the first area shear modulus relative to static force. The proportion of area occupied by the second area in the center area in the planar view is 0%-83%.

Owner:AGC INC

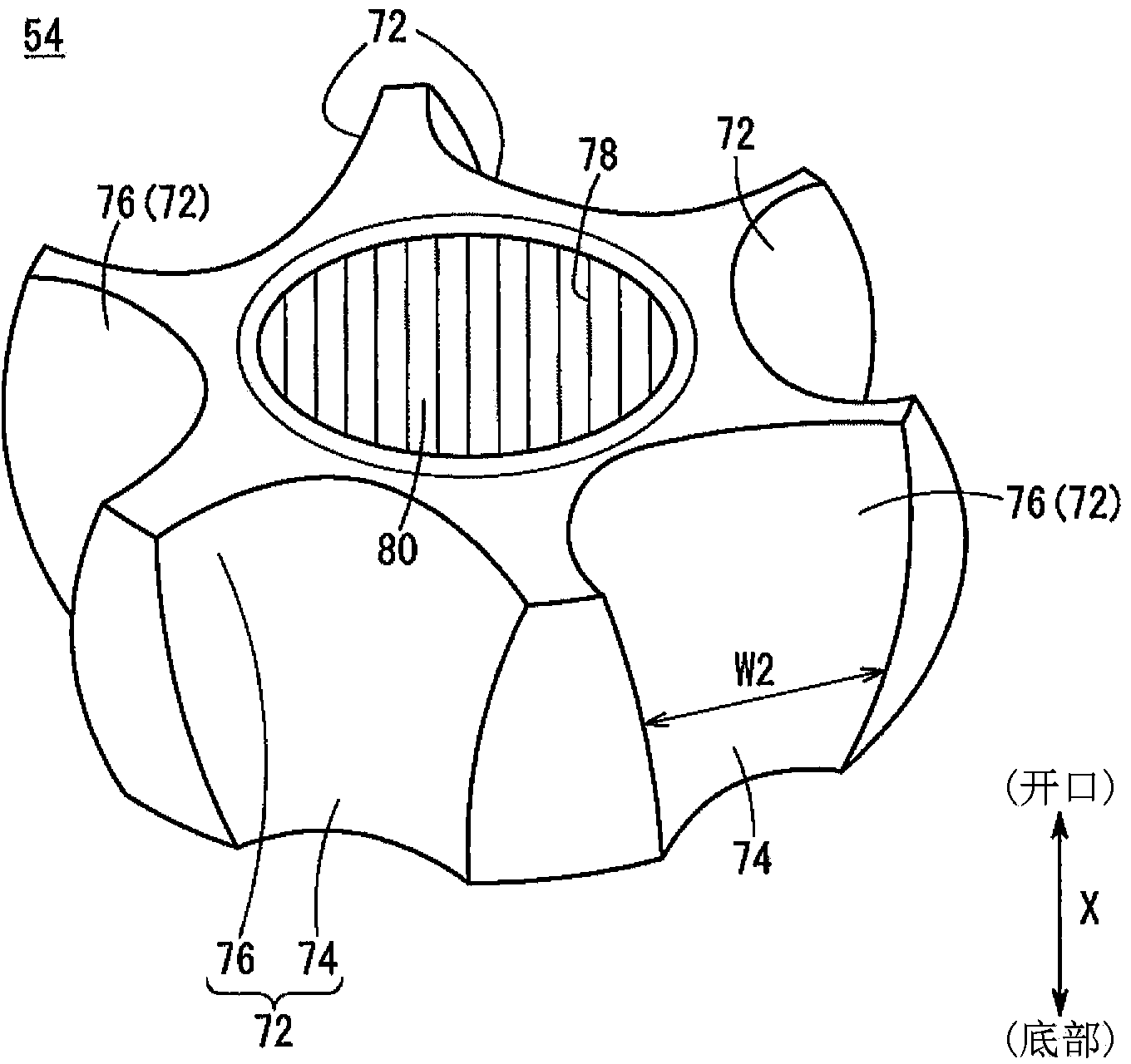

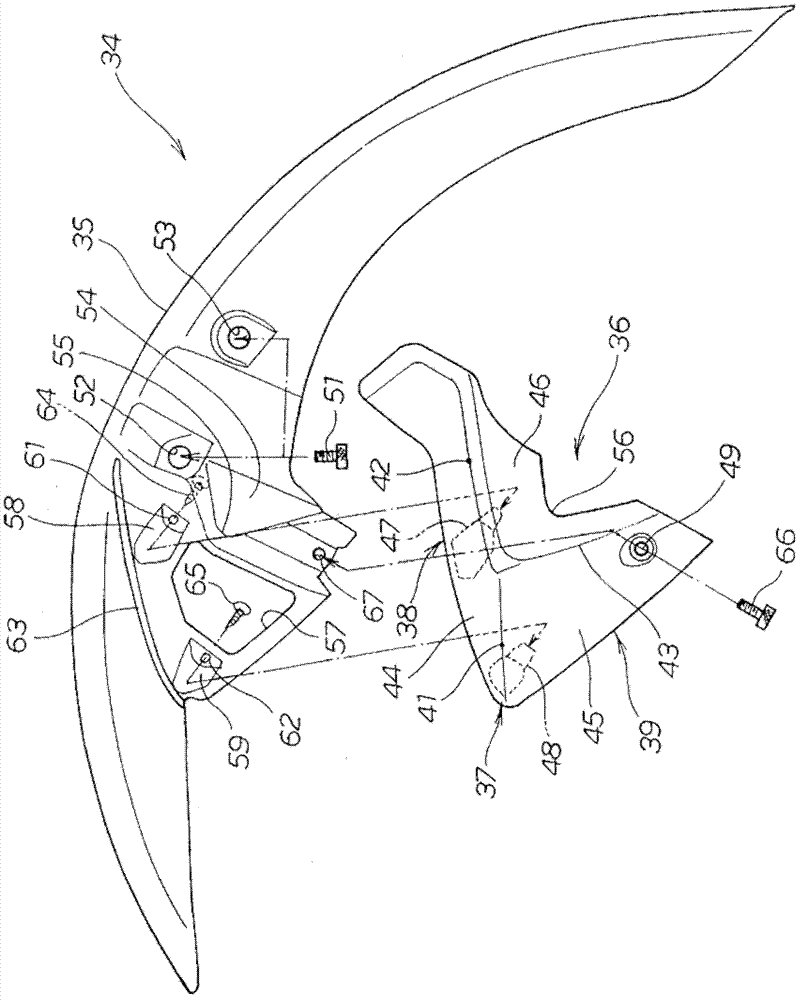

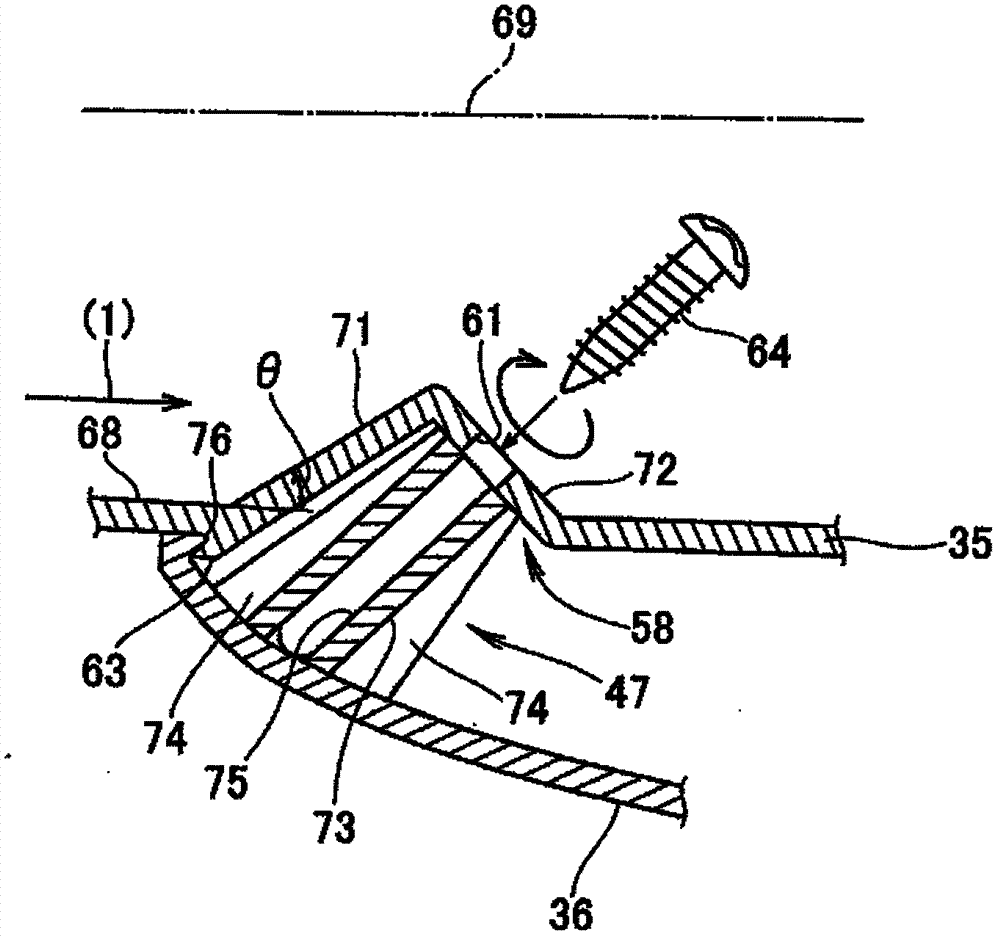

Insert, holder, and cutting tool using said insert and holder

ActiveCN102387883APrevent rotationHigh repeatabilityLathesTurning toolsEngineeringMechanical engineering

Owner:KYOCERA CORP

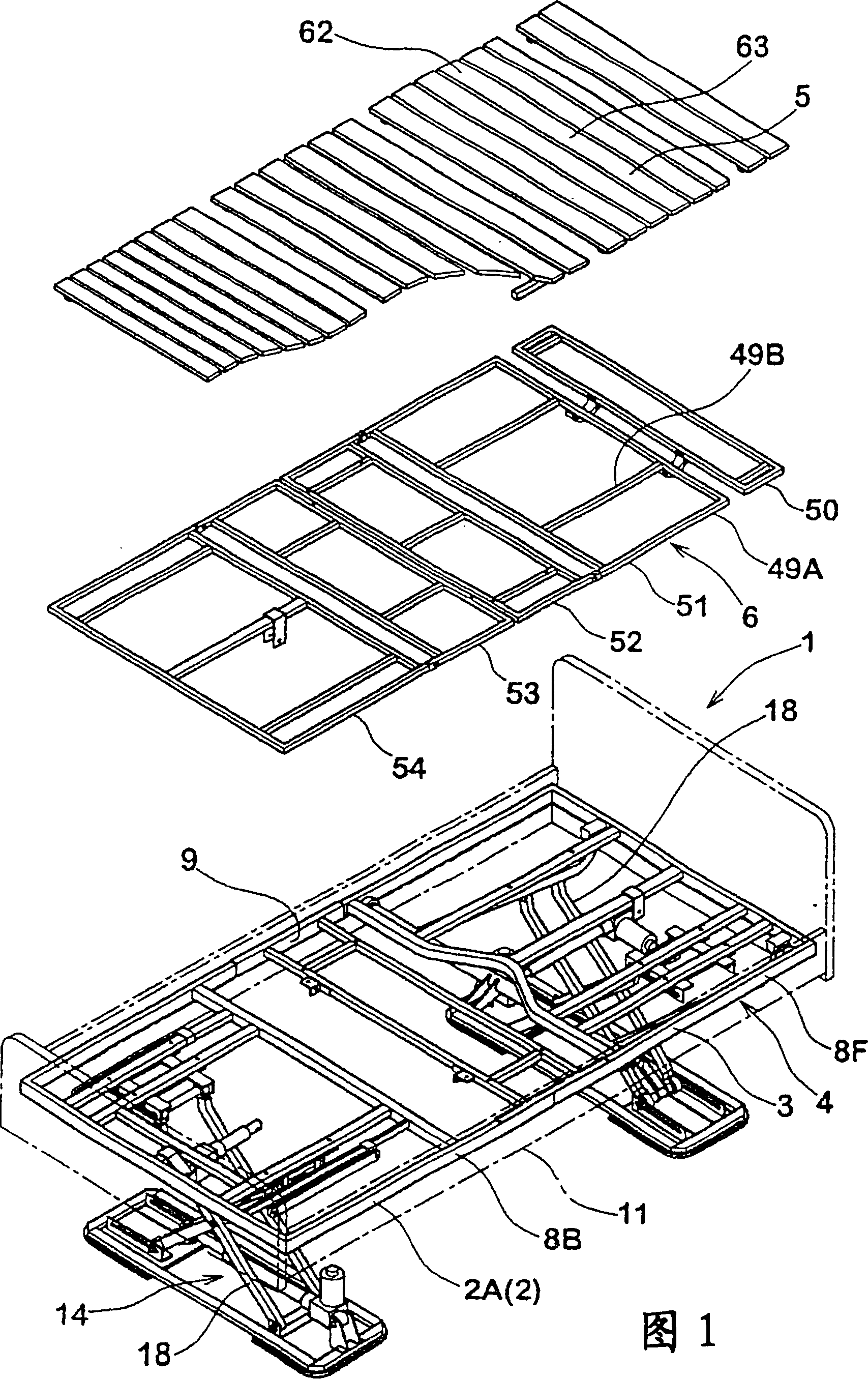

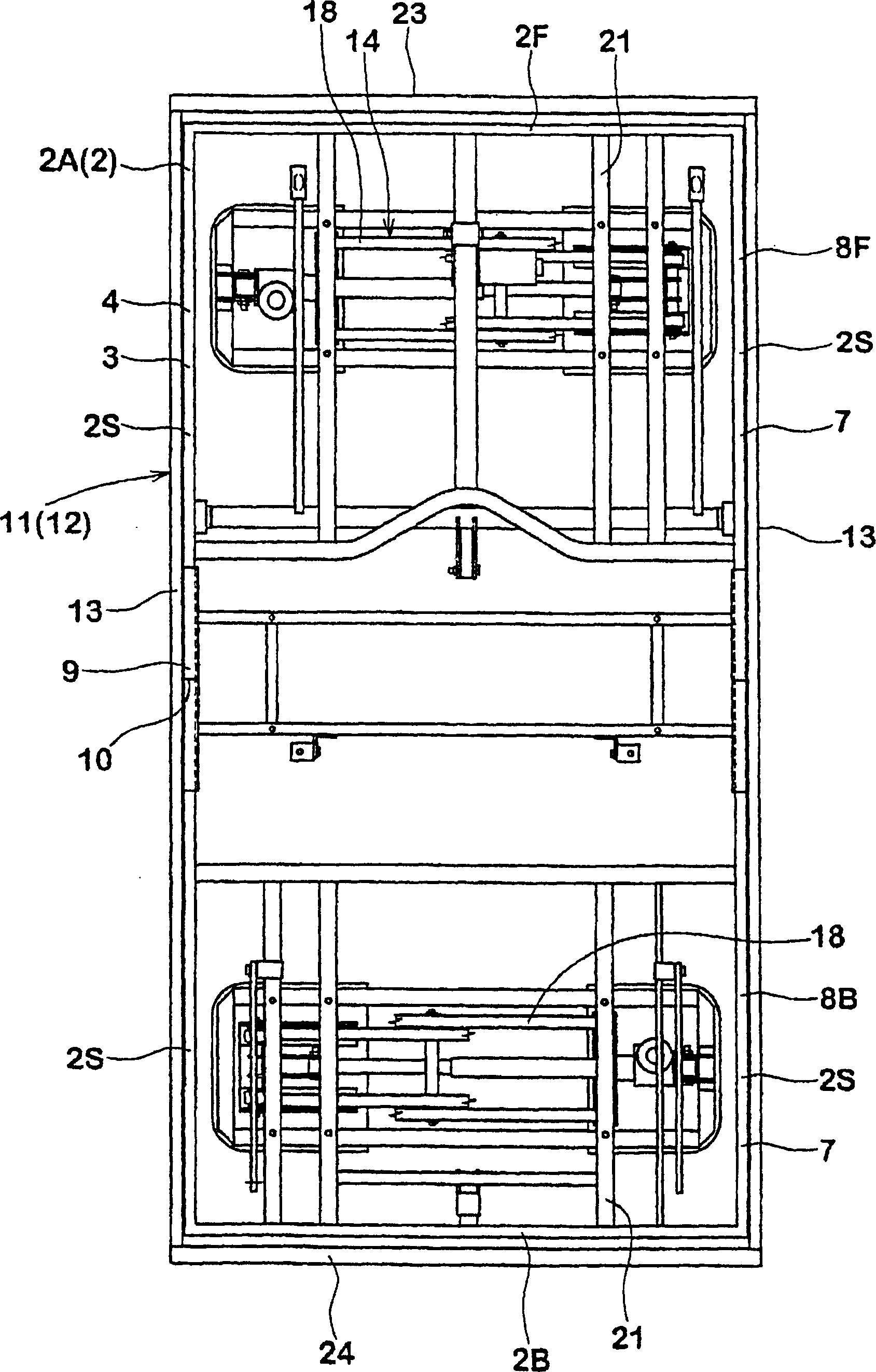

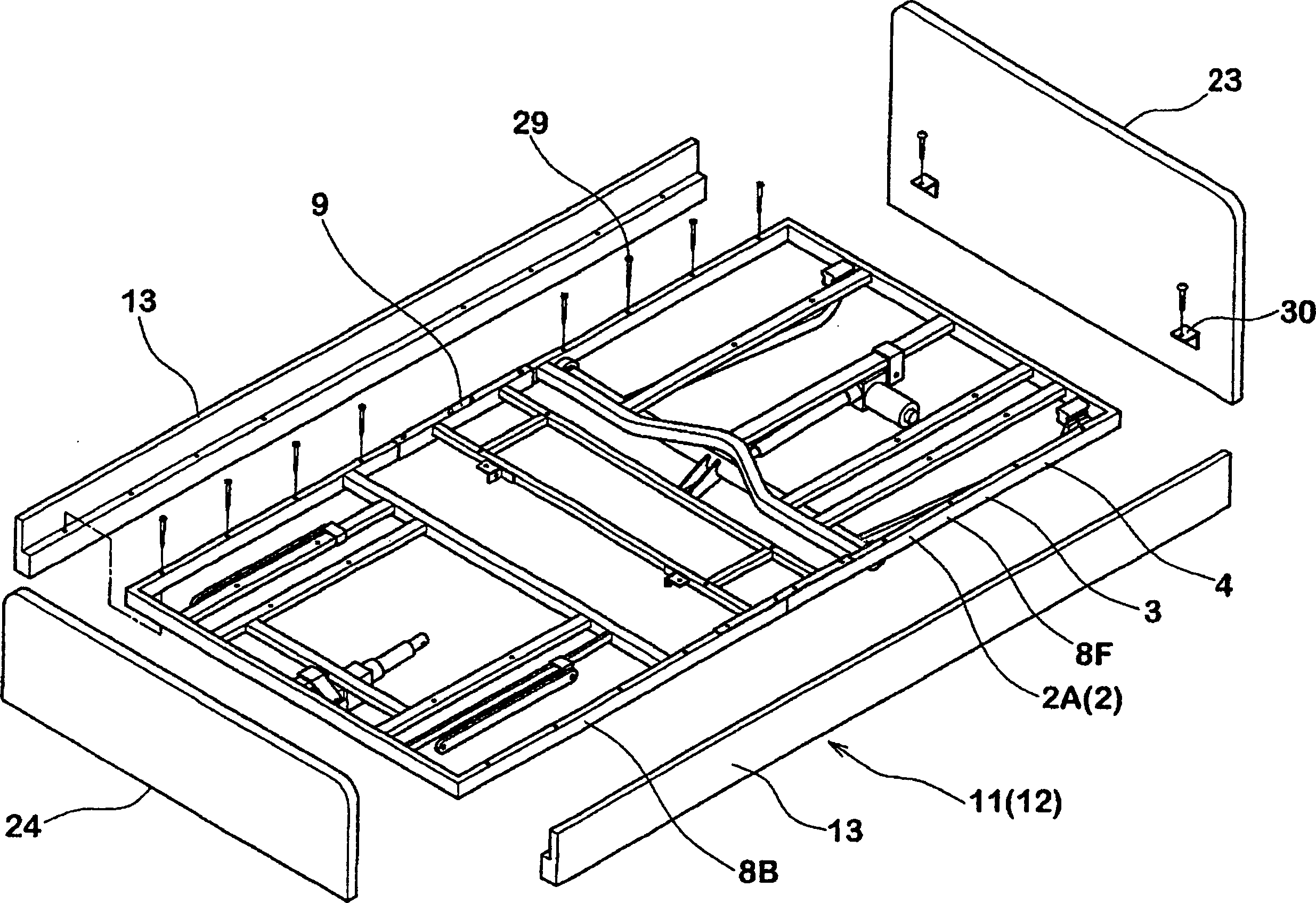

Bed

The present invention relates to a bed, it includes a bed frame body and a mattress frame. Said bed frame body has a frame body containing a rectangular peripheral frame, and said mattress frame has a bearing face for bearing mattress. Said frame body is formed from two frame half-bodies, a connecting frame and a reinforcement material. Said invention also provides the concrete structure of every frame half-body and connection mode of all the above-mentioned components.

Owner:ATEX CO LTD

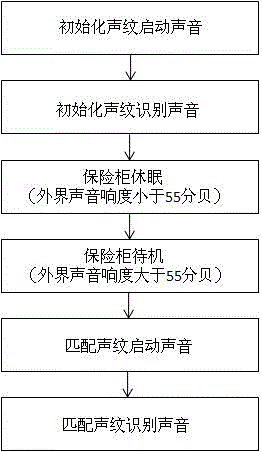

Novel double-unlocking safe case

InactiveCN104631998AImprove securityFully rigidElectric permutation locksIndividual entry/exit registersSpeech rateComputer science

The invention discloses a novel double-unlocking safe case. A fingerprint and voiceprint double-recognition system is adopted for the safe case, and voiceprint recognition control is particularly enhanced. The mode that voice frequency is randomly extracted, and people are made to read after the voice frequency is adopted for the system, so that it is avoided that someone deliberately imitates the speed and tone of a user in speaking a fixed sentence, and thus the safety of the safe case is further improved. A lock of the safe case is in a semi-circular-ring shape, no gradient exists, and the lock cannot be pried open with a hard plate from the outside; besides, a door seam is very narrow, and a tool cannot be inserted into the case to damage the lock.

Owner:句容智恒安全设备有限公司

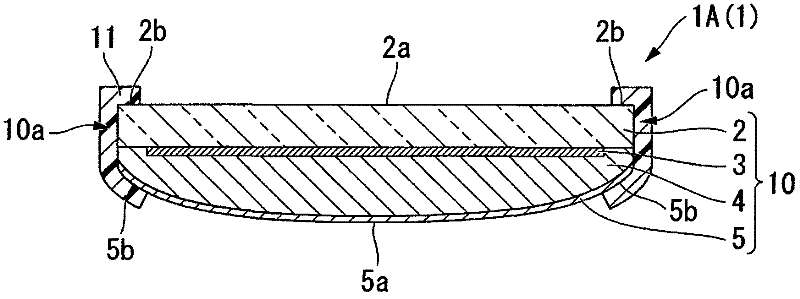

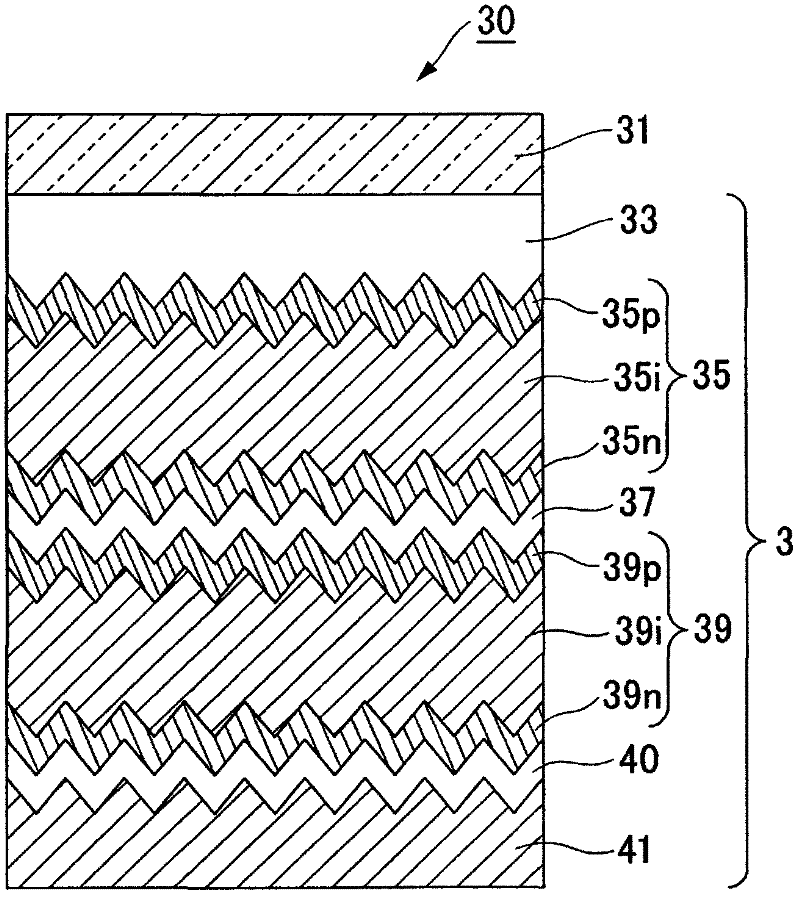

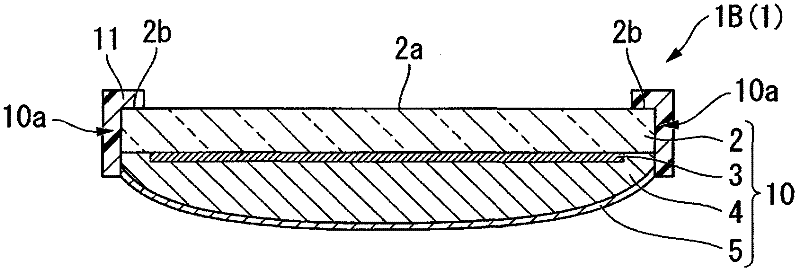

Frameless solar panel and manufacturing method thereof

InactiveCN102272945AFully rigidGuaranteed weather resistancePhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The frameless solar cell panel includes: a laminate (10) having an end portion (10a), and a first base material (2), a power generation portion (3), a sealing layer (4) and a back sheet are sequentially laminated (5) or the second substrate (6); and a silicon-based sealing material (11).

Owner:ULVAC INC

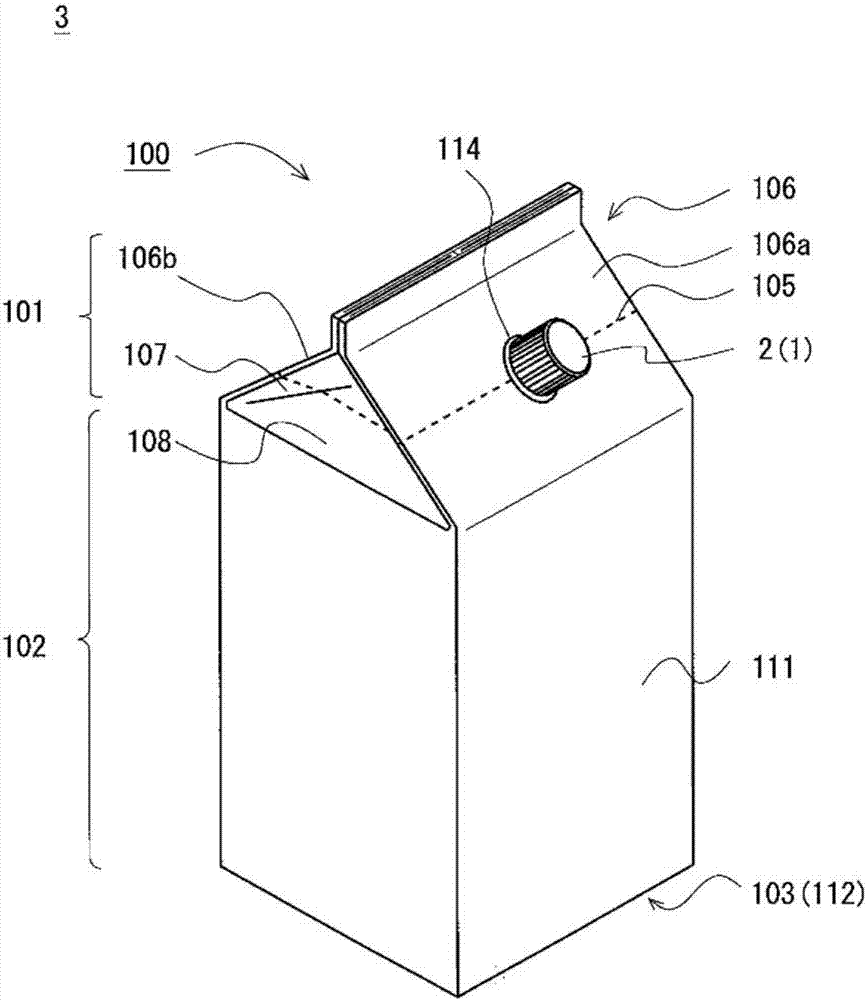

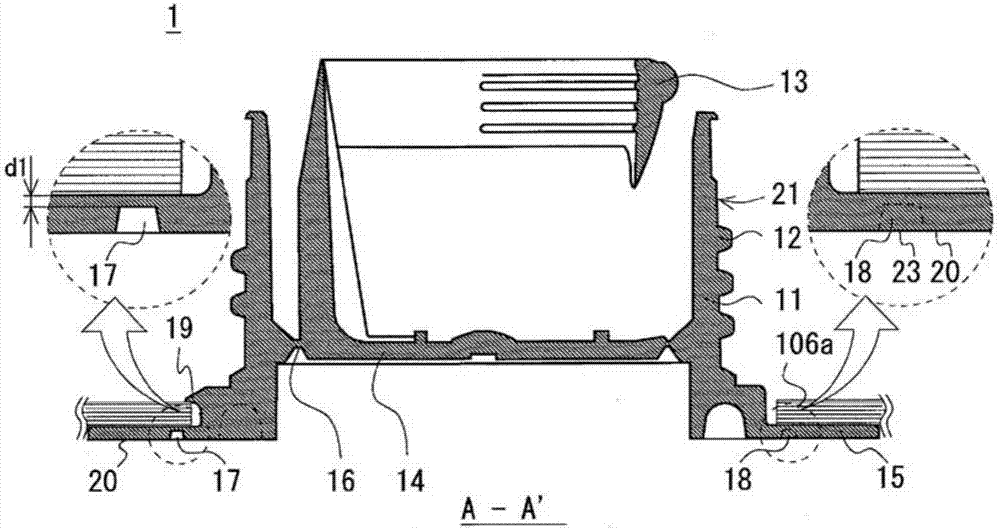

Pour spout stopper and packaging container

Provided is a pour spout stopper having ample rigidity that remains undamaged by ultrasonic vibration during welding, and is easily separated during disassembly of a packaging container; and a packaging container in which said stopper is used. This pour spout stopper is equipped with a round tubular side wall, and a disk-shaped flange part extending outward from the edge at one end of the side wall. Portions to be cut, which are recessed portions arranged in rings, and ribs provided to ring-shaped protruding portions or to the portions to be cut, are formed in the flange part.

Owner:TOPPAN PRINTING CO LTD

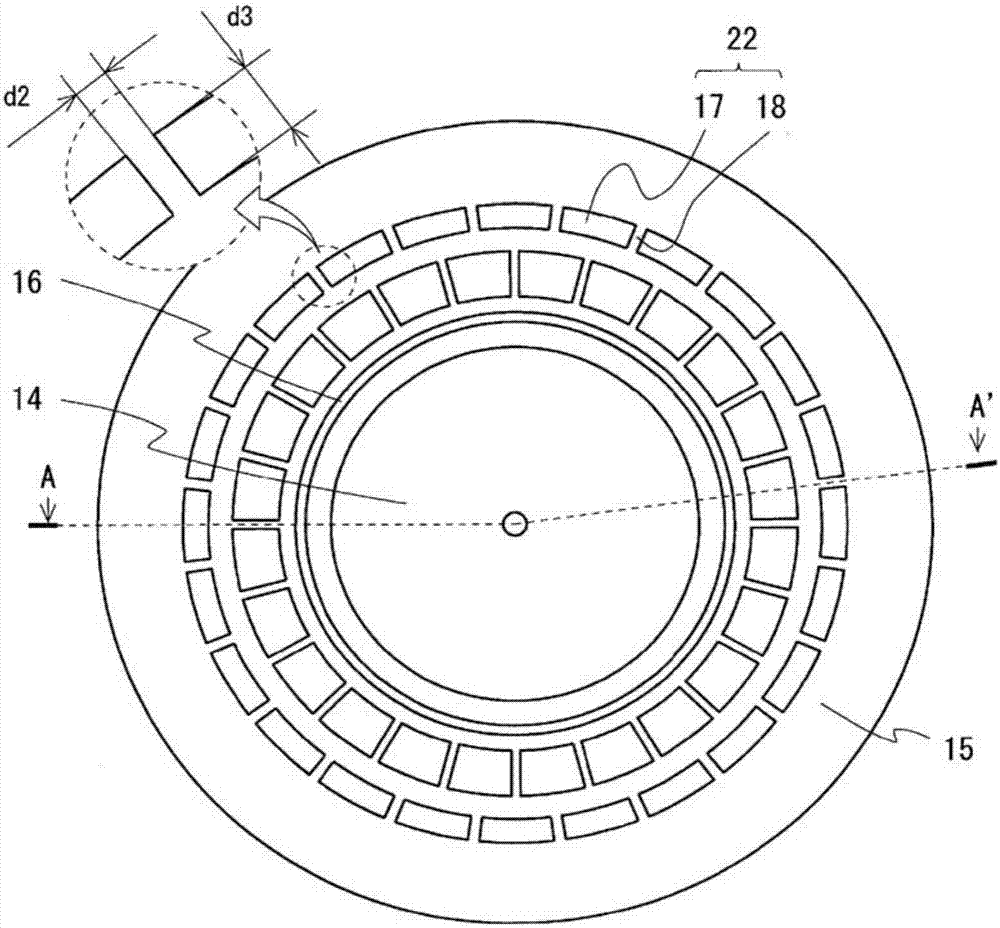

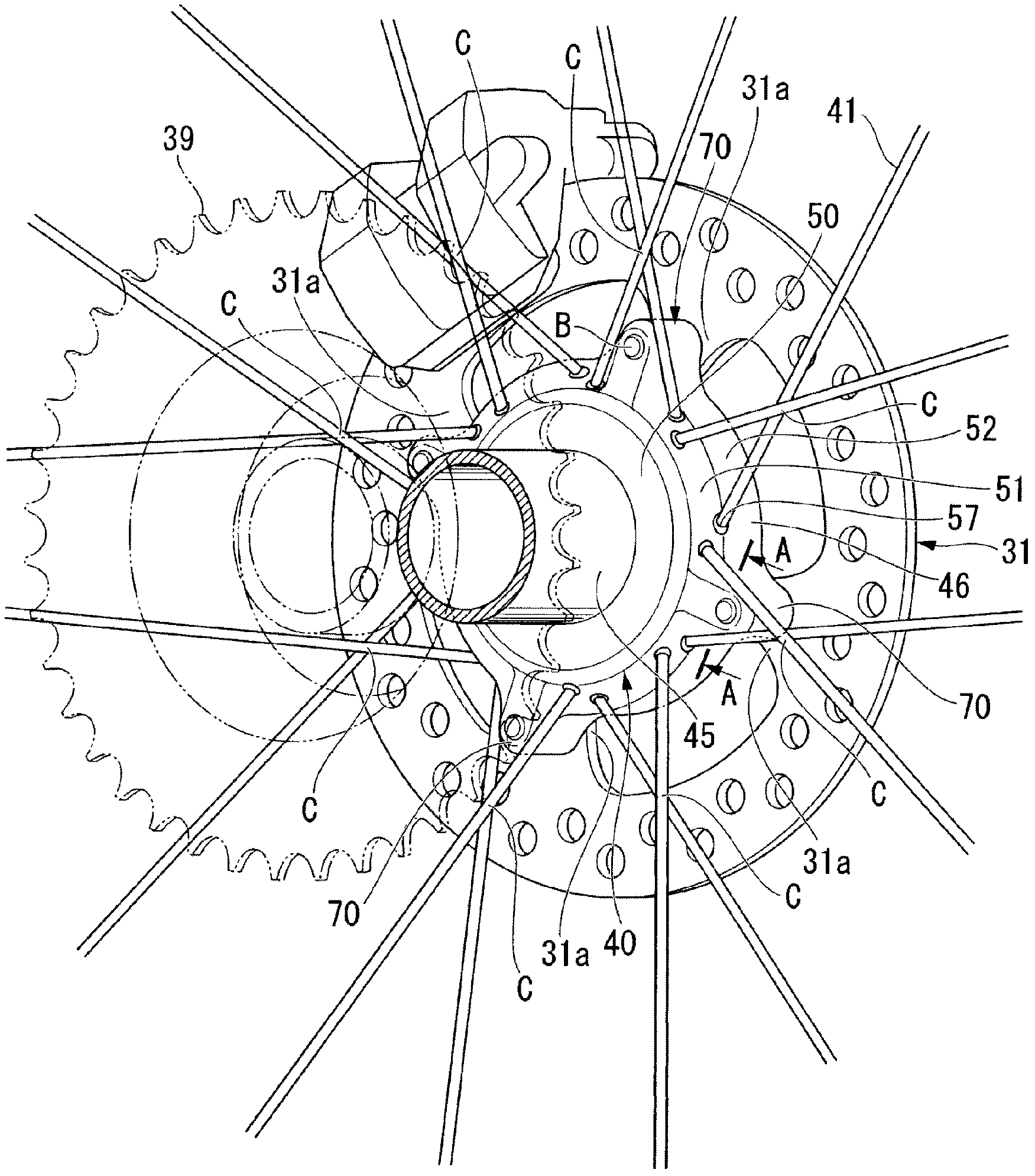

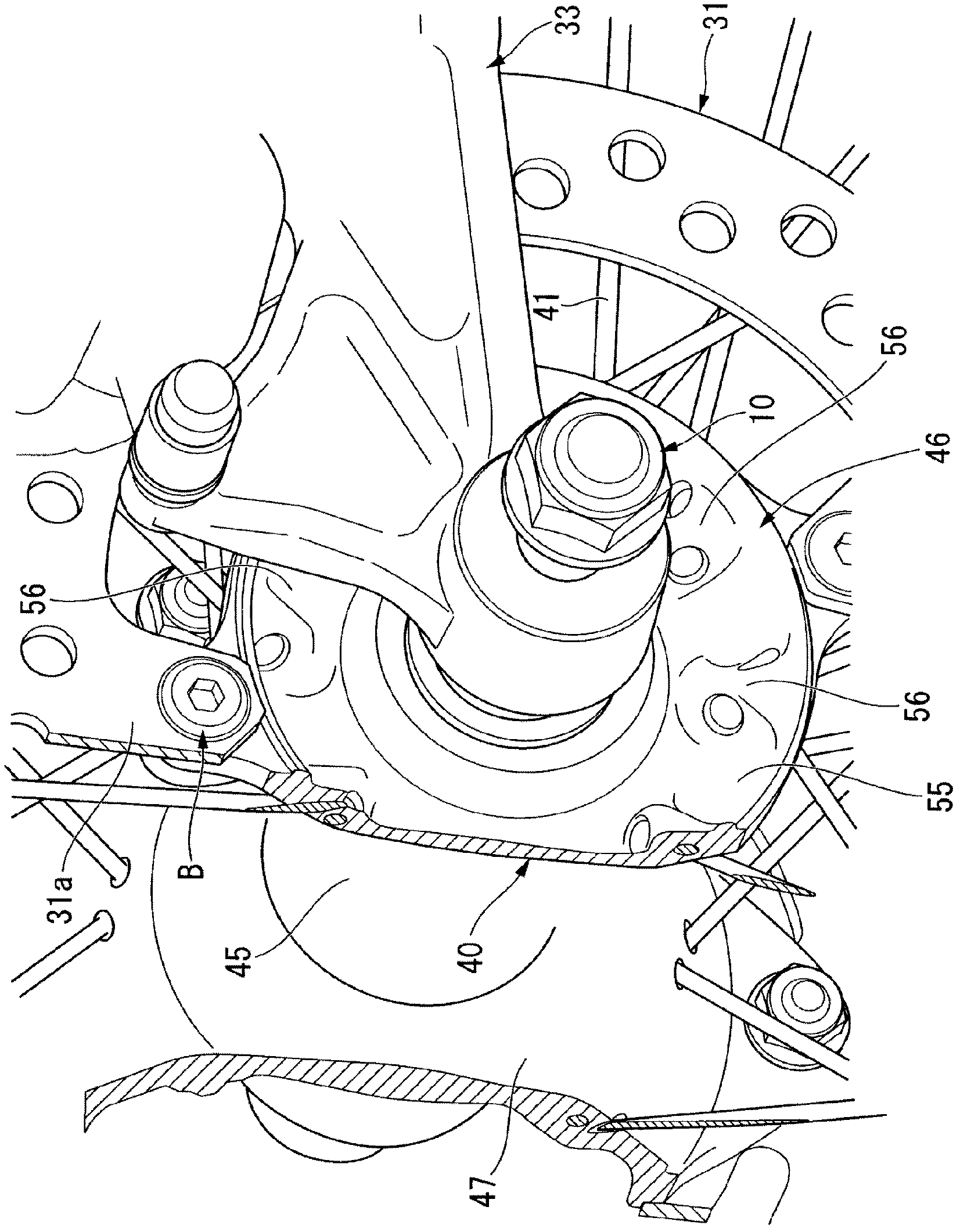

Wheel for vehicle

A wheel for a vehicle includes a hub, a rim, a plurality of spokes, and a disk member. The hub includes a flange portion, a plurality of spoke pedestals, and a plurality of disk member attaching portions. The flange portion outwardly spreads in a radial direction of the hub and is provided on one end portion of the hub in an axial direction of the hub. The spoke pedestals are provided at substantially regular intervals on an inner side of the flange portion and inwardly projects from the flange portion in the radial direction. The disk member attaching portions are provided at substantially regular intervals on an outer periphery of the flange portion and outwardly projects from the flange portion in the radial direction. The disk member attaching portions are provided between the spoke pedestals in a circumferential direction of the flange portion.

Owner:HONDA MOTOR CO LTD

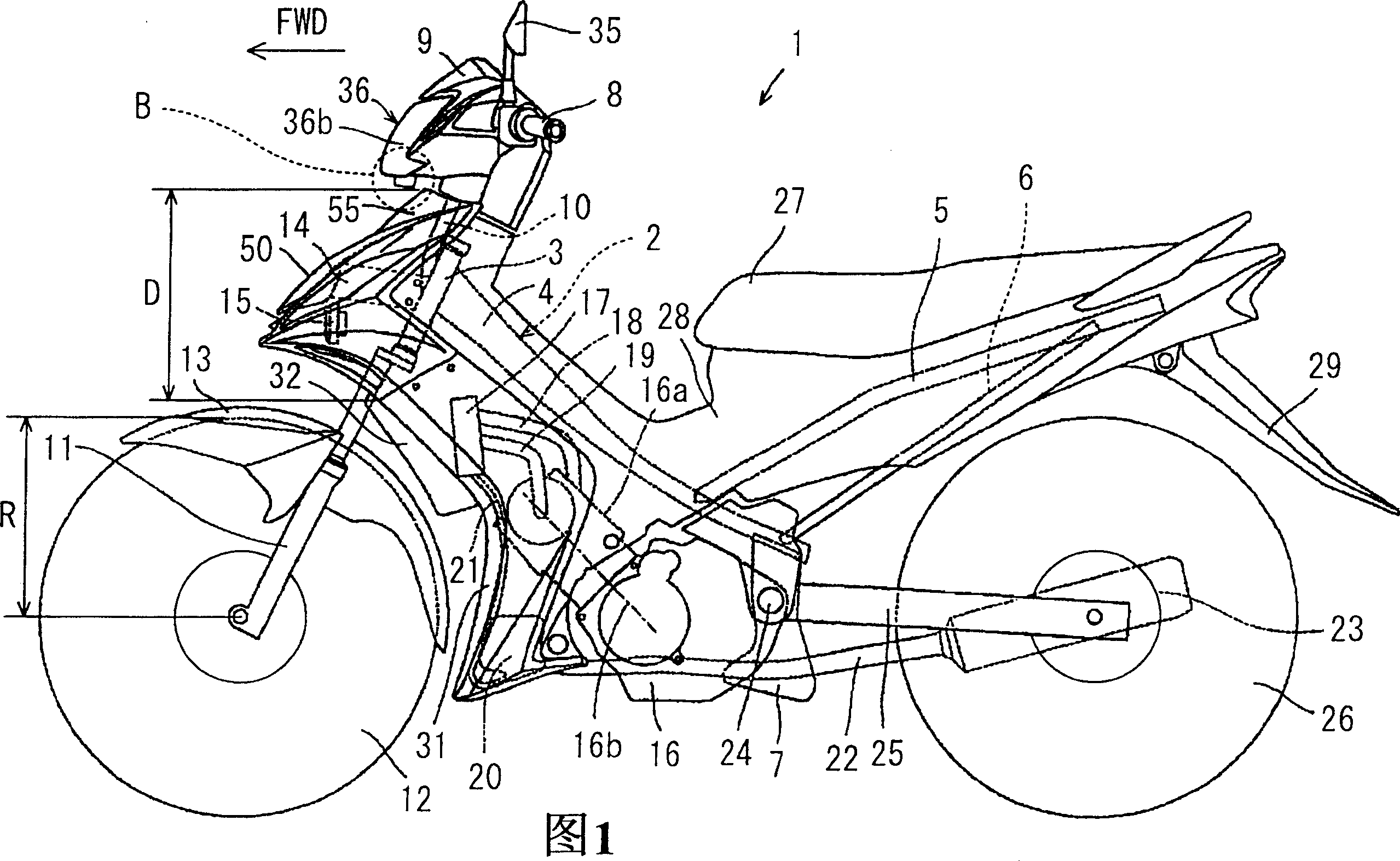

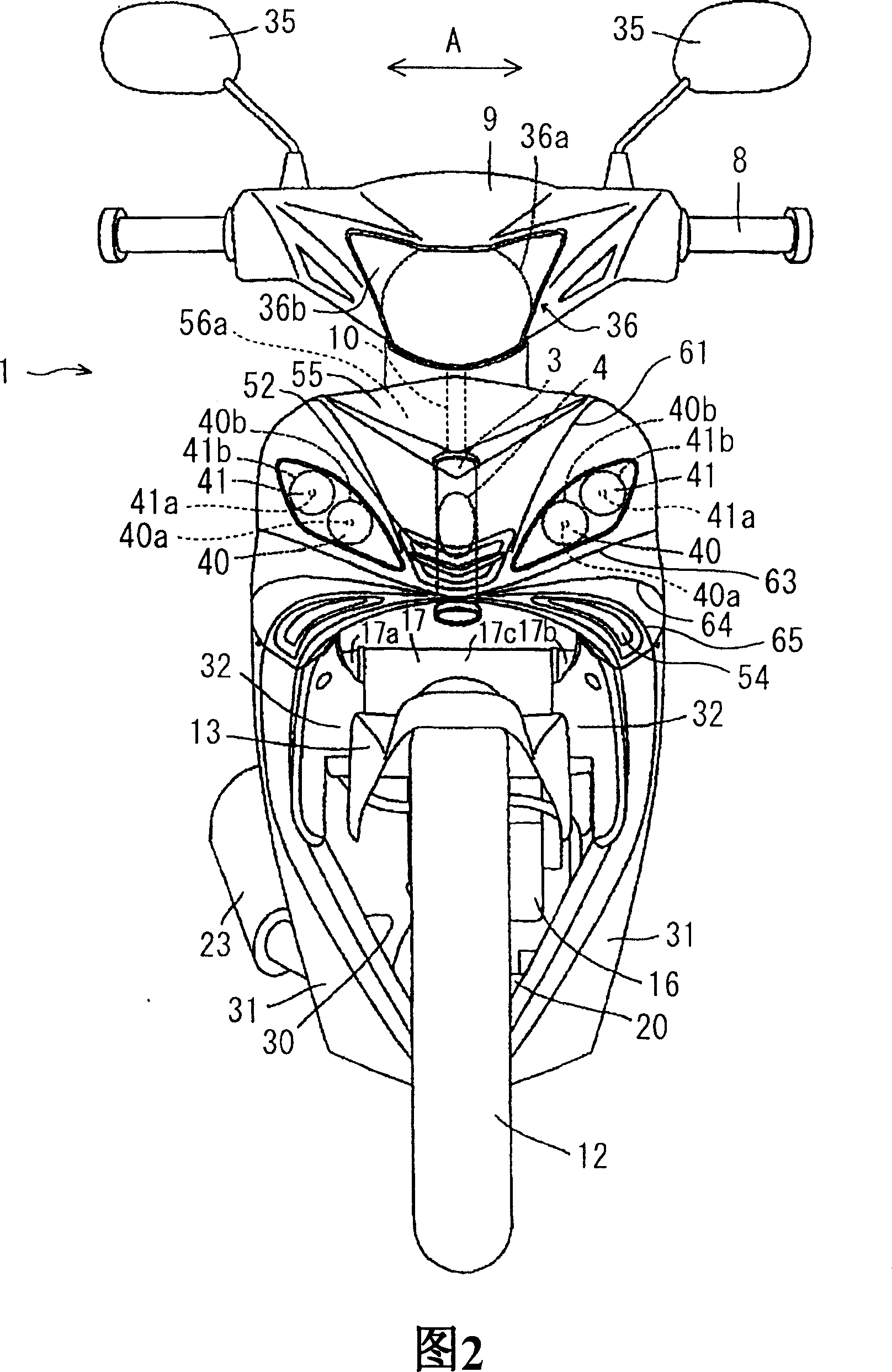

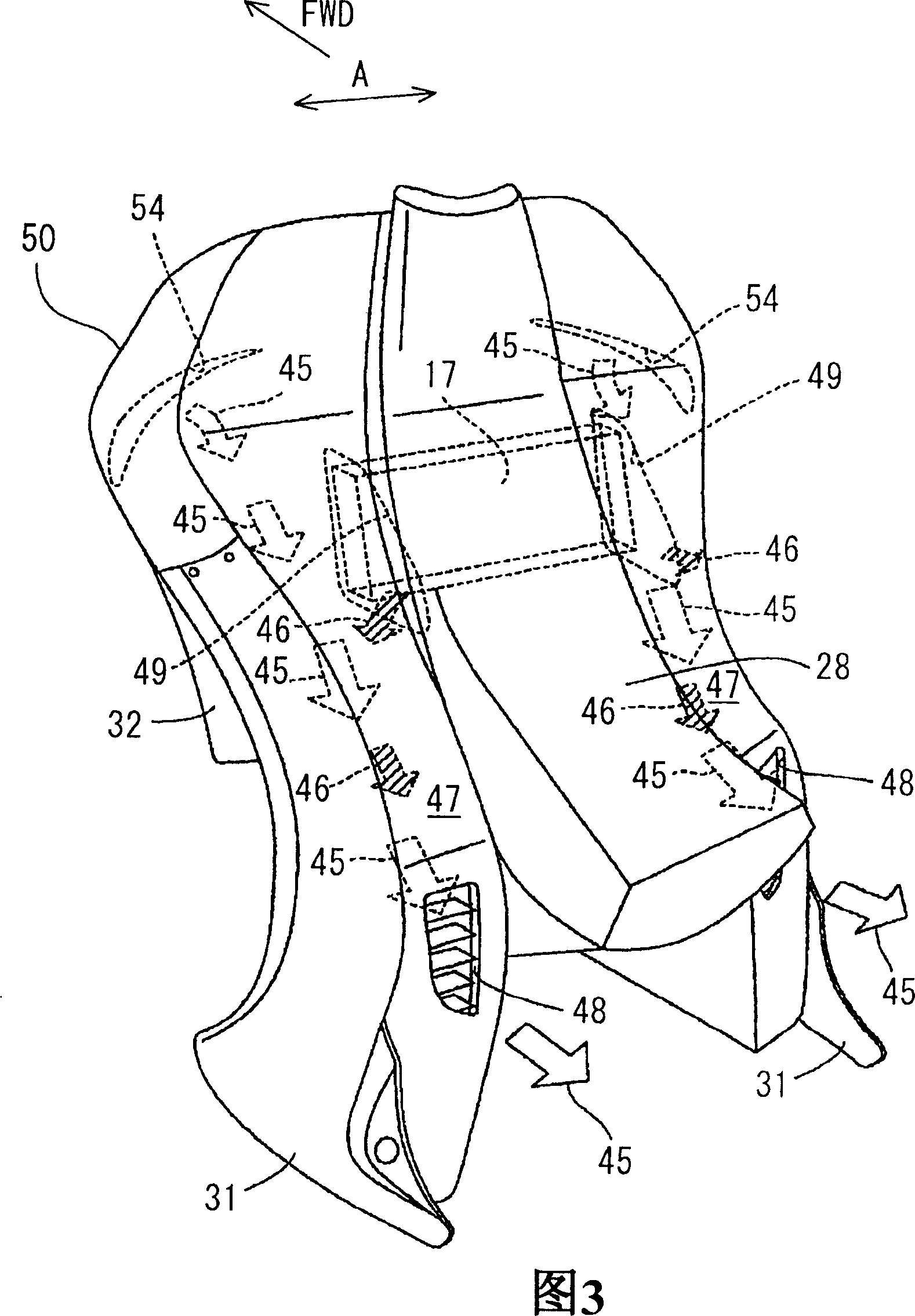

Front cowl and vehicle provided with the same

The present invention provides a front cowl that exhibits a sufficient stiffness even in use for underbone type motorcycles, etc., and a vehicle provided with the front cowl. The front cowl is formed into a shape, in which it extends obliquely rearward with a center point as a front end. The front cowl is formed with a horn opening, lighting openings, and baffle openings. The openings are arranged to be radial round a central portion as viewed from the front. The front cowl is formed with an irregular shape, which is defined by crest lines and trough lines. The crest lines are arranged between the horn opening and the lighting openings. The trough lines and the crest lines are arranged between the lighting openings and the baffle openings.

Owner:YAMAHA MOTOR CO LTD

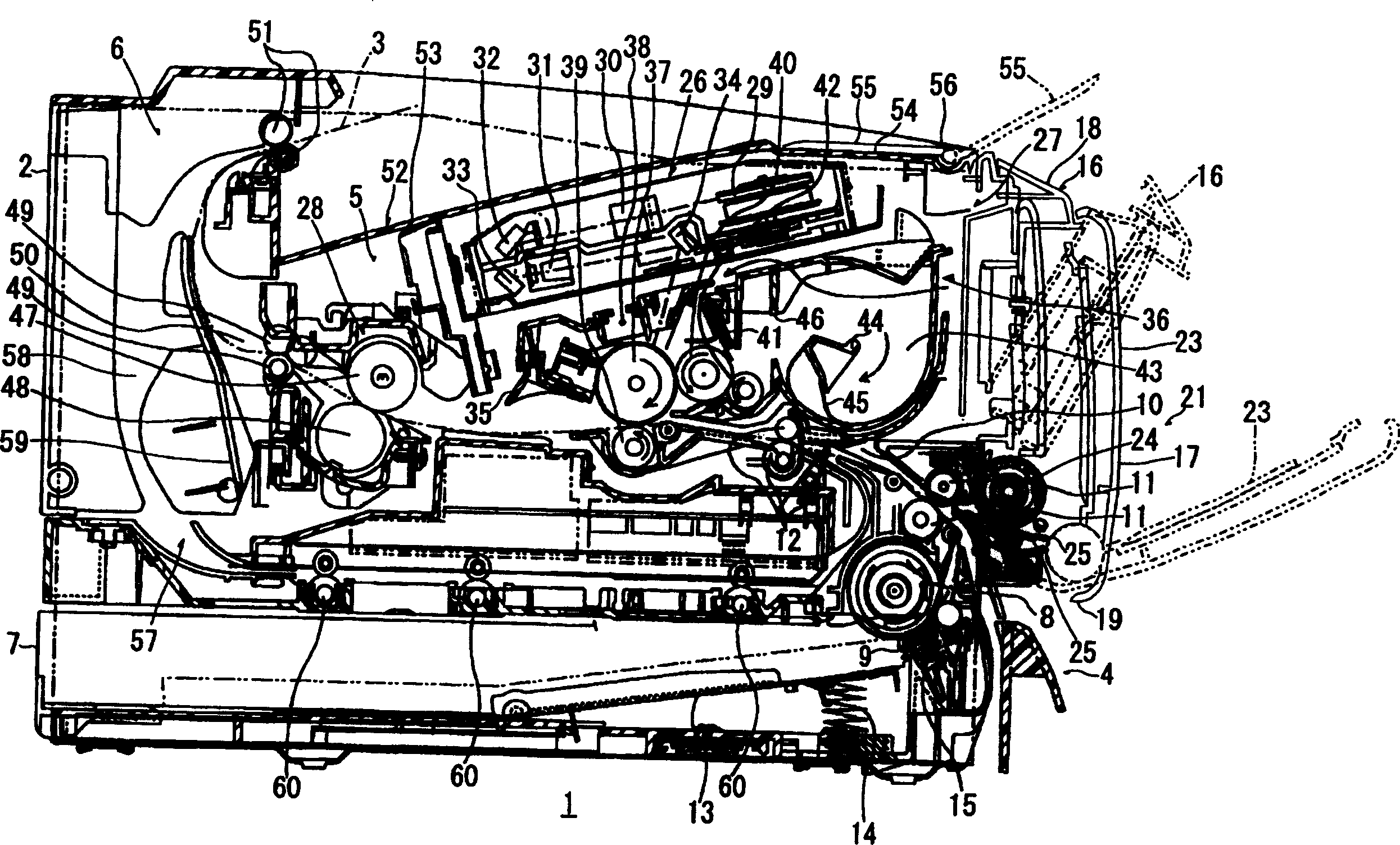

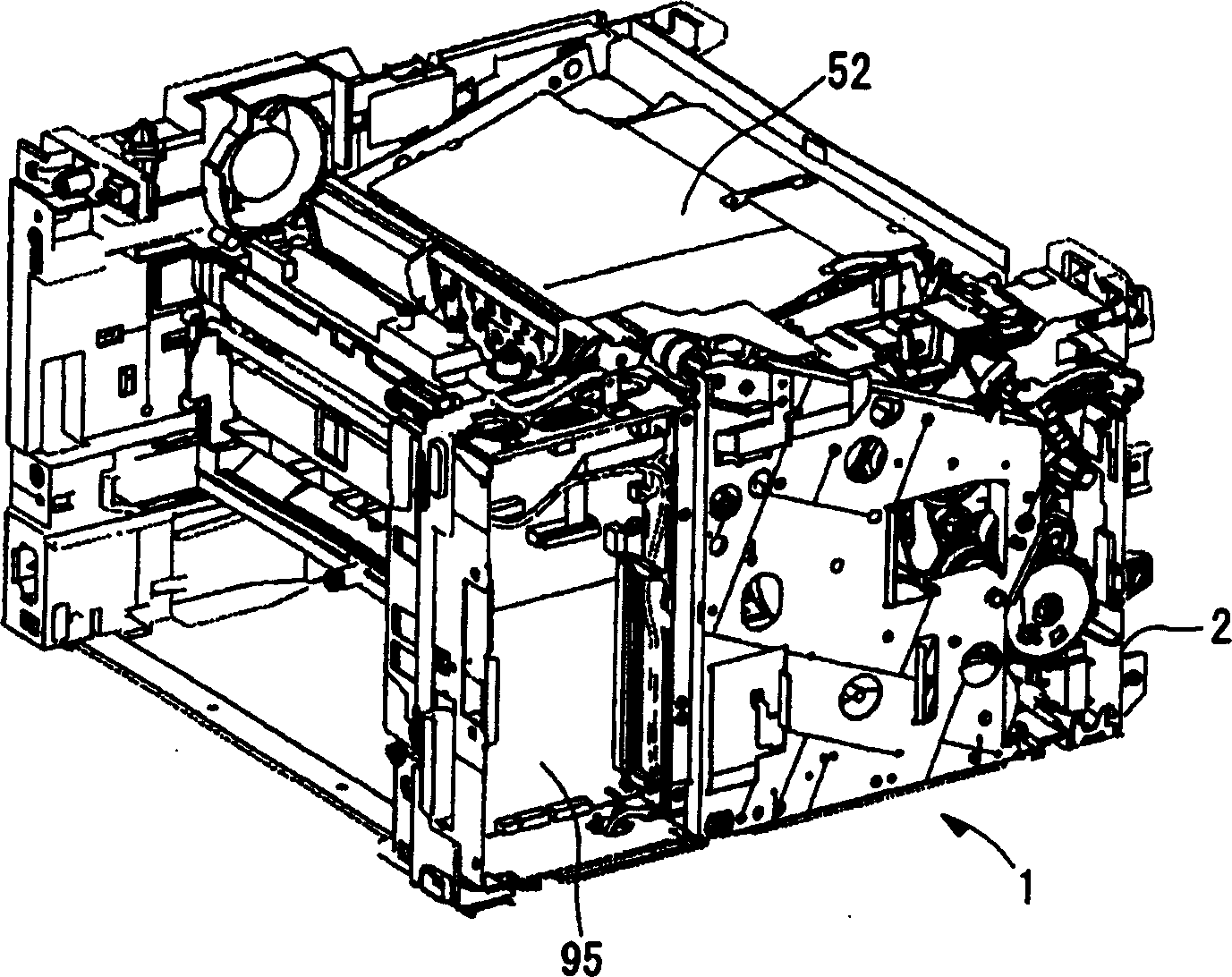

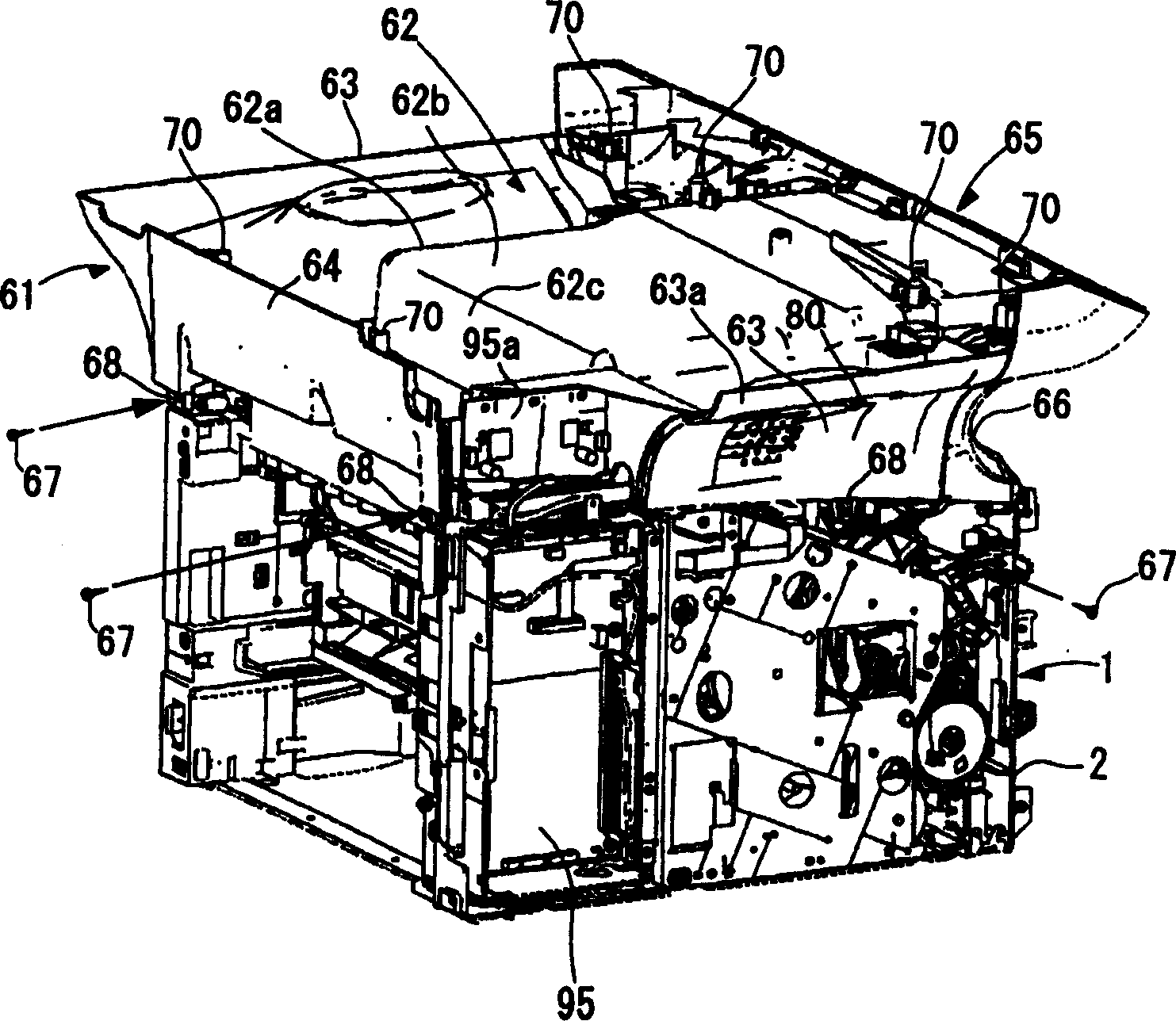

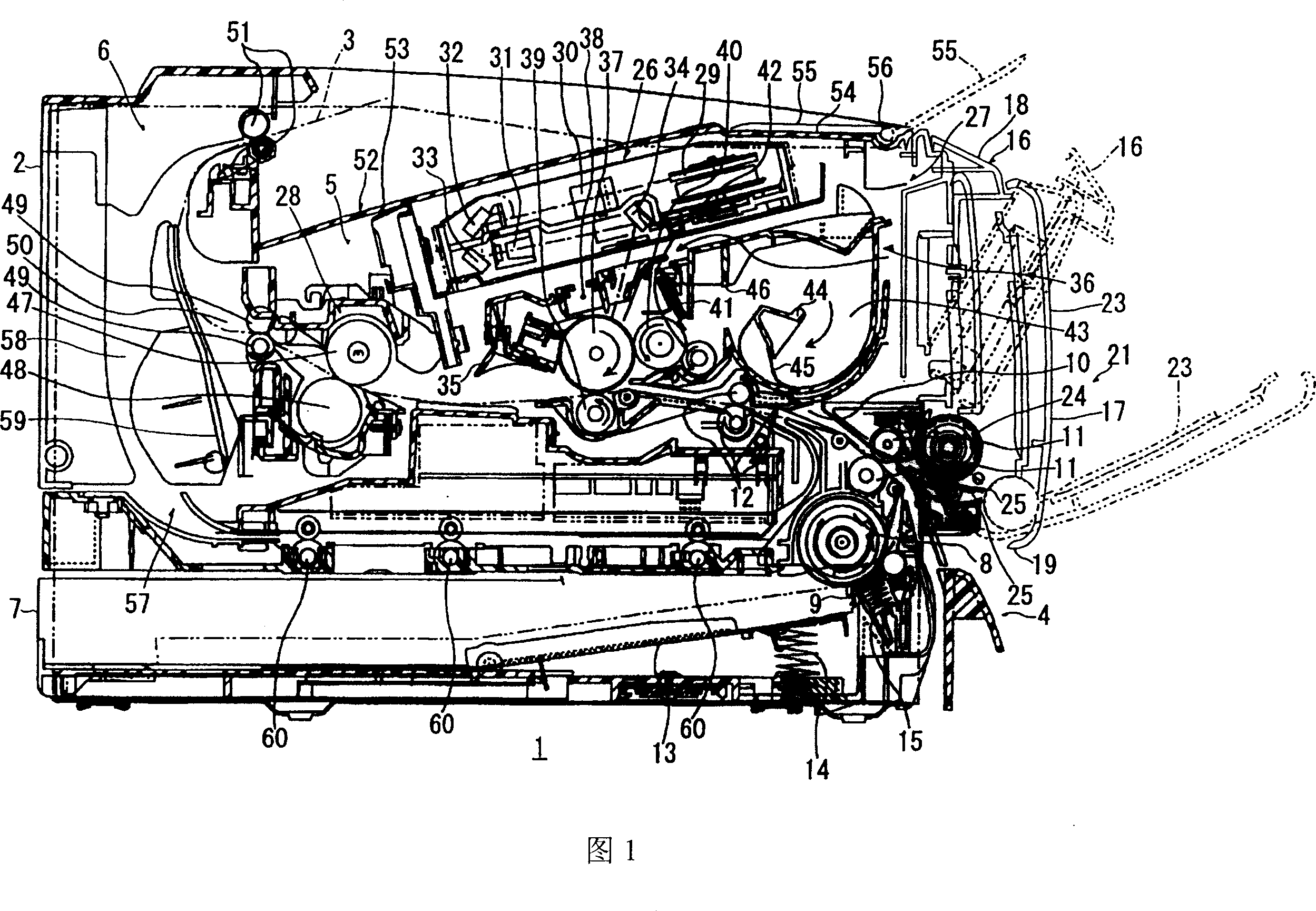

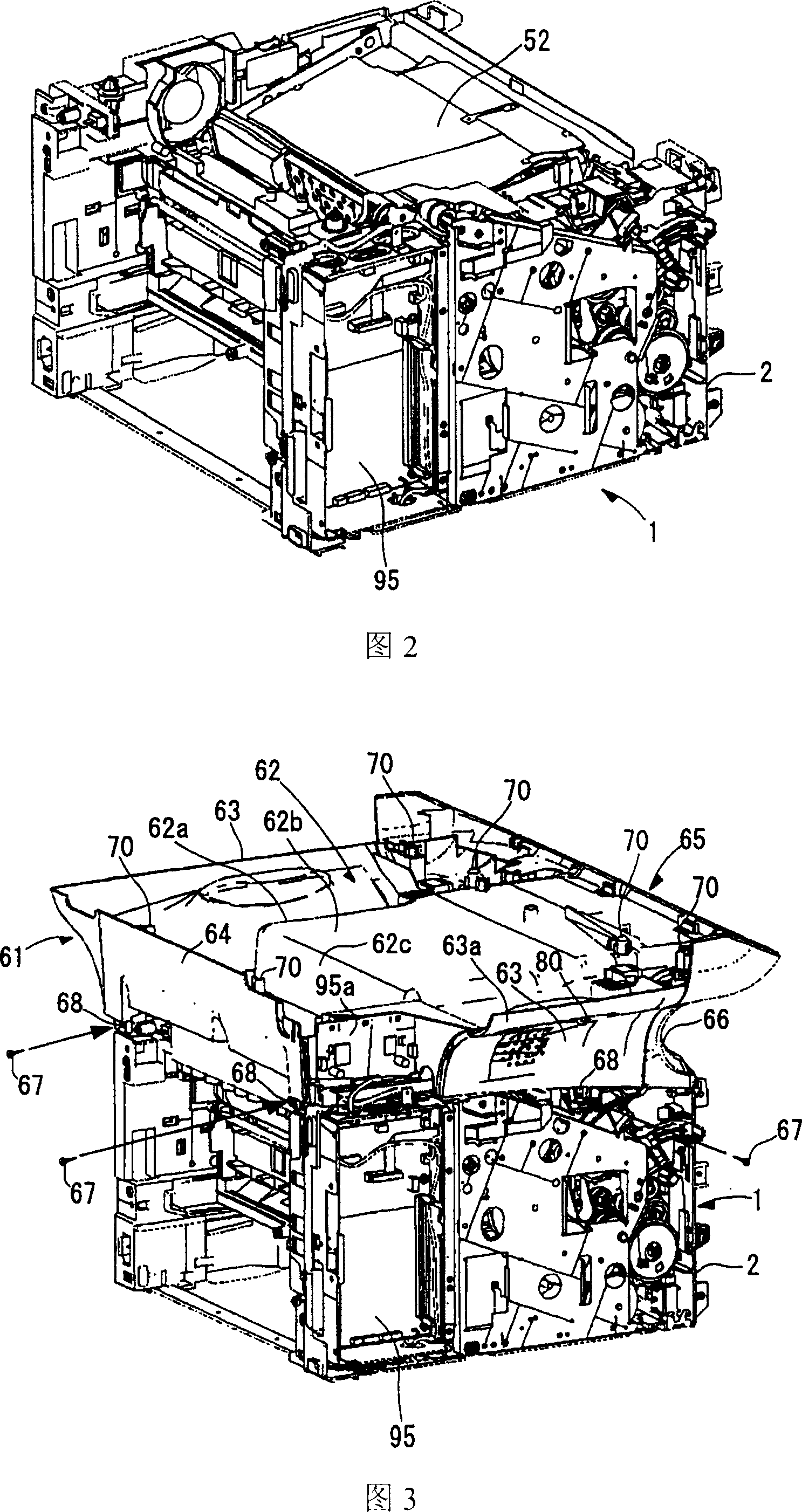

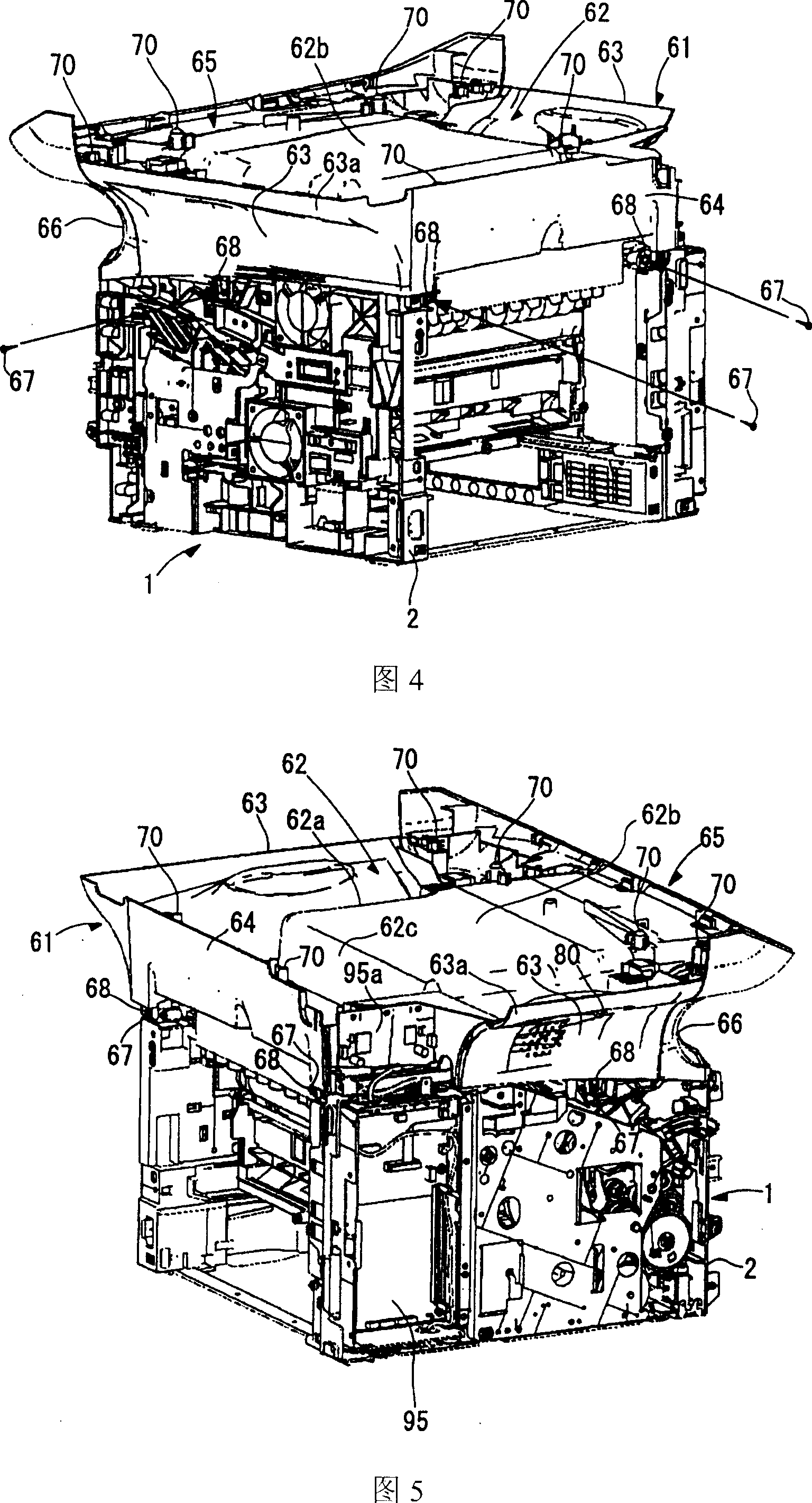

Image forming apparatus

InactiveCN1486853AImprove rigidityFully rigidHectographic duplicationElectrographic process apparatusOperabilityEngineering

To improve the rigidity of an image forming apparatus provided with an ejection part between an image reading device and an image forming apparatus body. Since a joint cover 61 is attached to a printer body 1, and a scanner unit 81 is supported by the joint cover 61, a connection part consisting of the joint cover 61 between the printer body 1 and the scanner unit 81 is made as a paper ejecting part 99 to eject paper 3, and the front end of the side cover 63 of the joint cover 61 is arranged on the front side of the front end 82a of an original platen 82, so that a front end recess 66 recessed on a backside is formed at the front end. Thus, the ejected paper 3 is easily taken out from the recess of the front end recess 66 while supporting the scanner unit 81 by the side cover 63, and the improvement of operability is attained while securing the rigidity of the apparatus.

Owner:BROTHER KOGYO KK

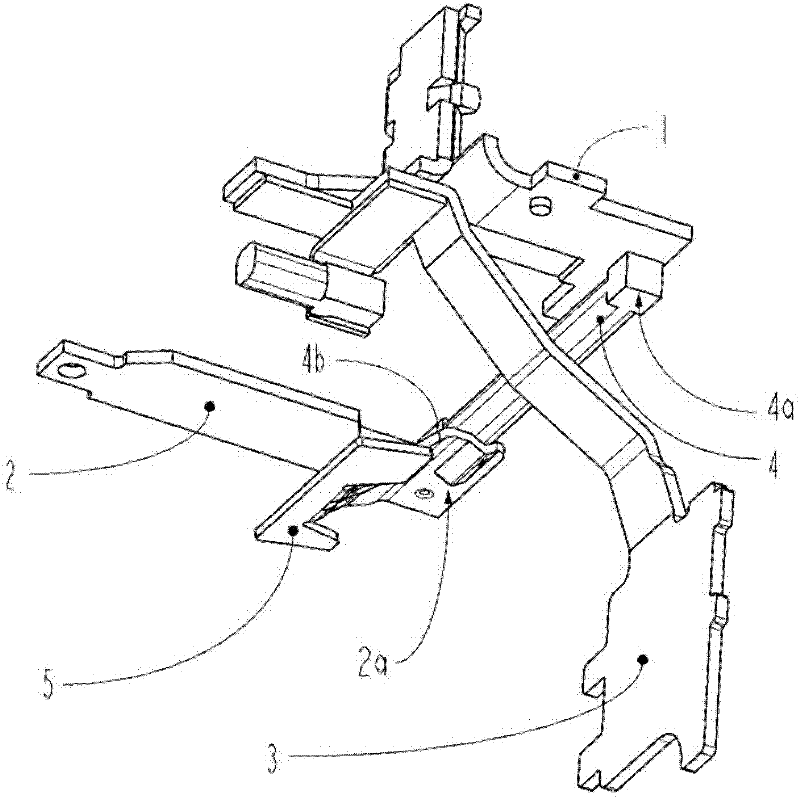

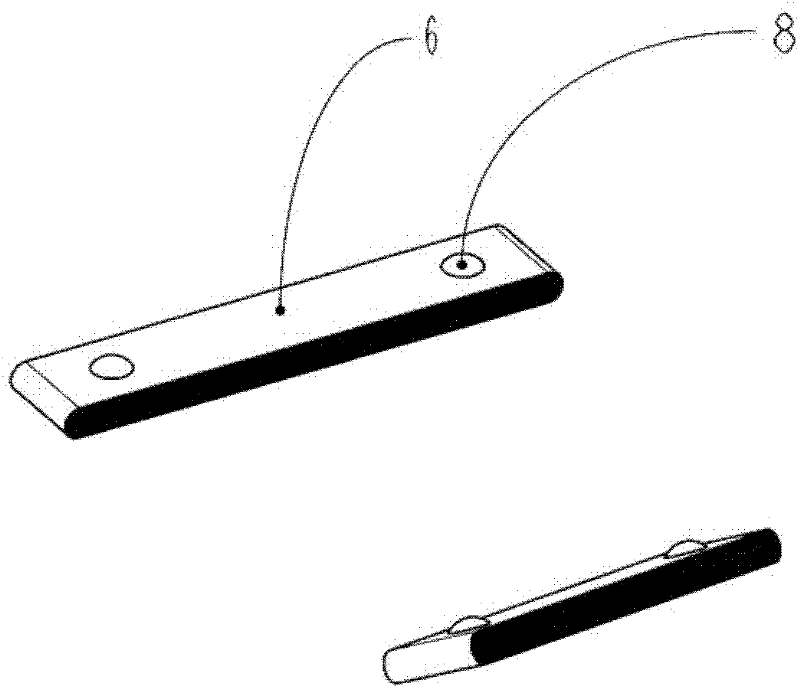

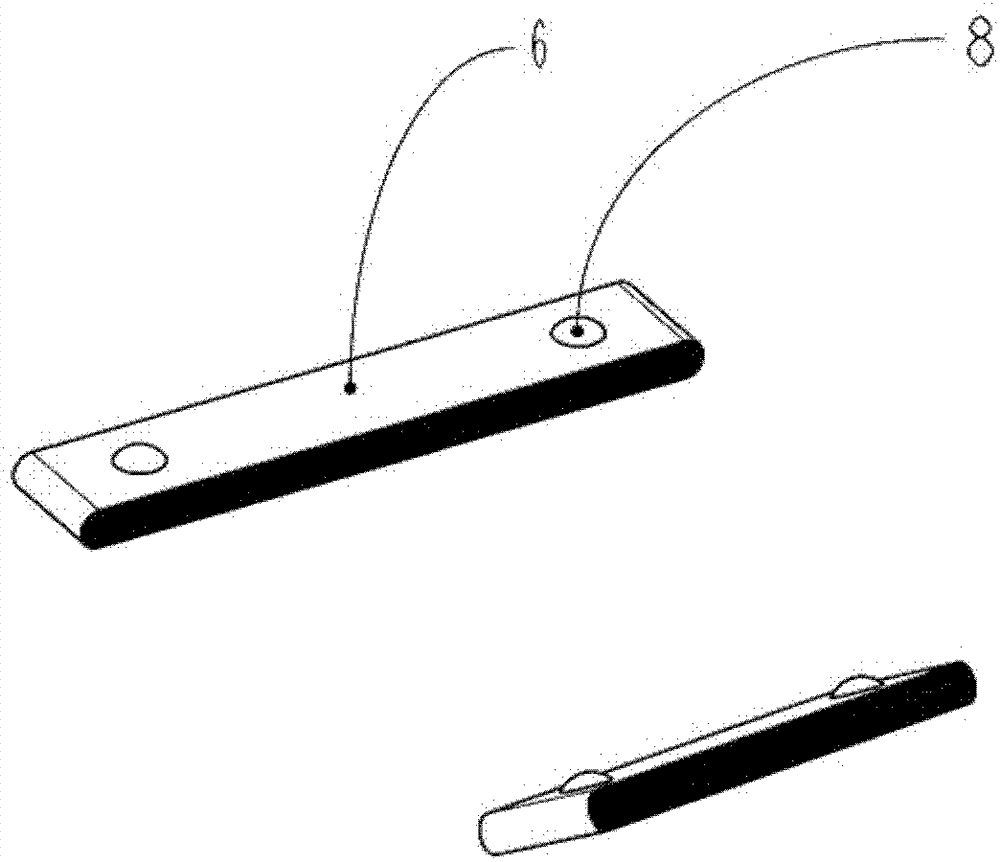

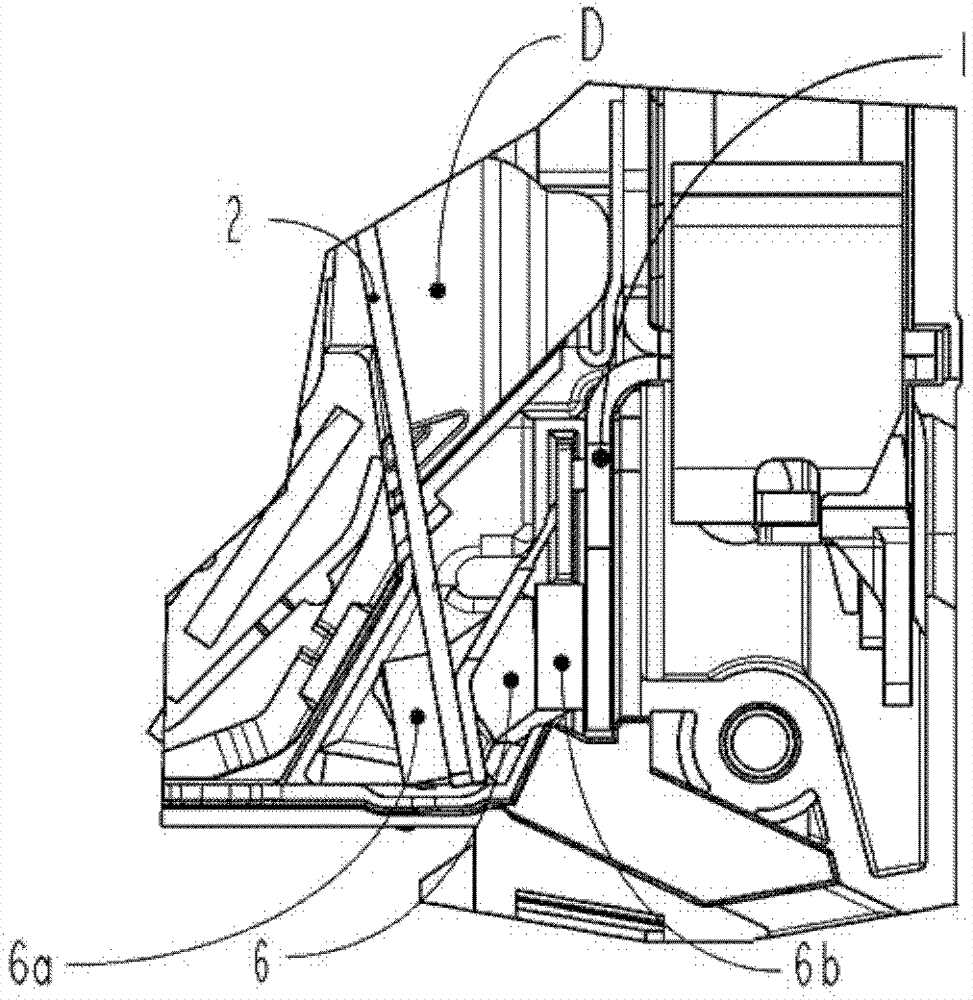

Device for electrical connection and circuit breaker

ActiveCN102315049ASimple designReduce volumeProtective switch terminals/connectionsProtective switch operating/release mechanismsElectrical connectionEngineering

The invention relates to a device for electrical connection and a circuit breaker. The device is applied in an electrical switch device to connect a foot of a bimetal strip with a contact strip. The bimetal strip can be moved via an adjusting screw so as to be thermally adjusted. The device is characterized in that the device has a flat conductive component (6) fixed on the contact strip (1) and the bimetal strip (2), wherein the conductive component is formed by at least one continuous conductive element. The conductive element is wound and flattened, so as to have a length substantially corresponding to a gap between the foot of the bimetal strip and the contact strip and to have a semi-rigid structure. The semi-rigid structure permits the deformation of the conductive component under the adjusting effect of the adjusting screw (7) so as to permit the displacement of the bimetal strip (2), while being sufficiently rigid for assuring relative positioning of the foot of the bimetal strip with respect to the contact strip.

Owner:SCHNEIDER ELECTRIC IND SAS

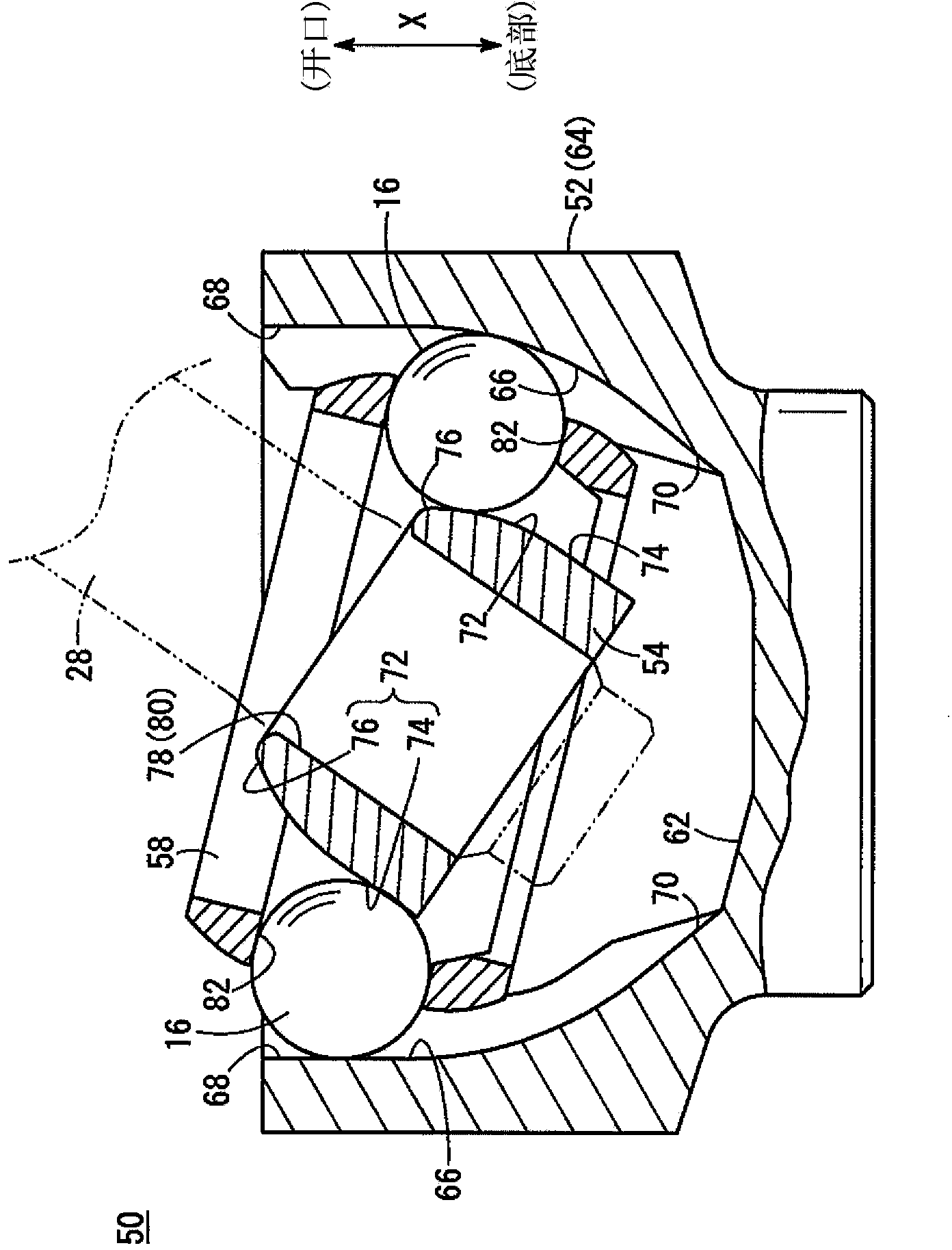

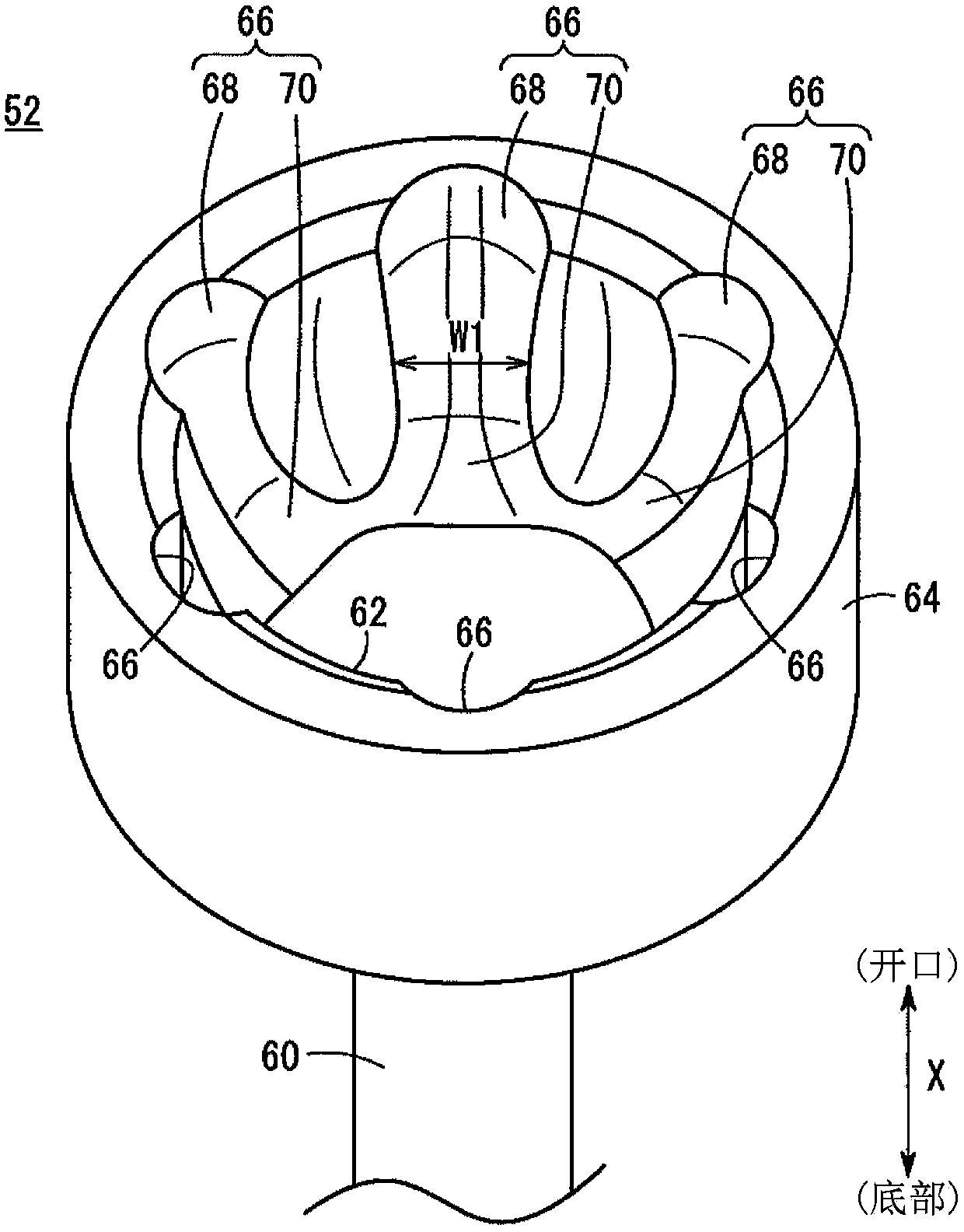

Fixed type constant velocity joint

The invention relates to a fixed type constant velocity joint (50). A bottomed hole (62) for inserting an inner member (54) and a retainer (58) is provided in an outer member (52) forming the fixed type constant velocity joint (50). On the inner wall of the bottomed hole (62), an outer side ball groove (66) for allowing a torque transmission ball (16) to slide is provided in a manner of extending from the opening side to the bottom side of the bottomed hole (62). The outer side ball groove (66) is formed by a first groove (68) and a second groove (70) which is connected with the first groove (68) and wide in width compared with the first groove (68), for example, the first groove (68) is positioned at the opening side of the bottomed hole (62), and the second groove (70) is positioned at the bottom side of the bottomed hole (62). The torque transmission ball (16) slides in the first groove (68) without entering into the second groove (70) when a rotating shaft (28) is in a range of an angle of inclination.

Owner:HONDA MOTOR CO LTD

Fastening device

InactiveCN102753773AGuaranteed rigidityAvoid breakingSpringsNon-rotating vibration suppressionEngineeringFastener

Owner:大仓宪峰

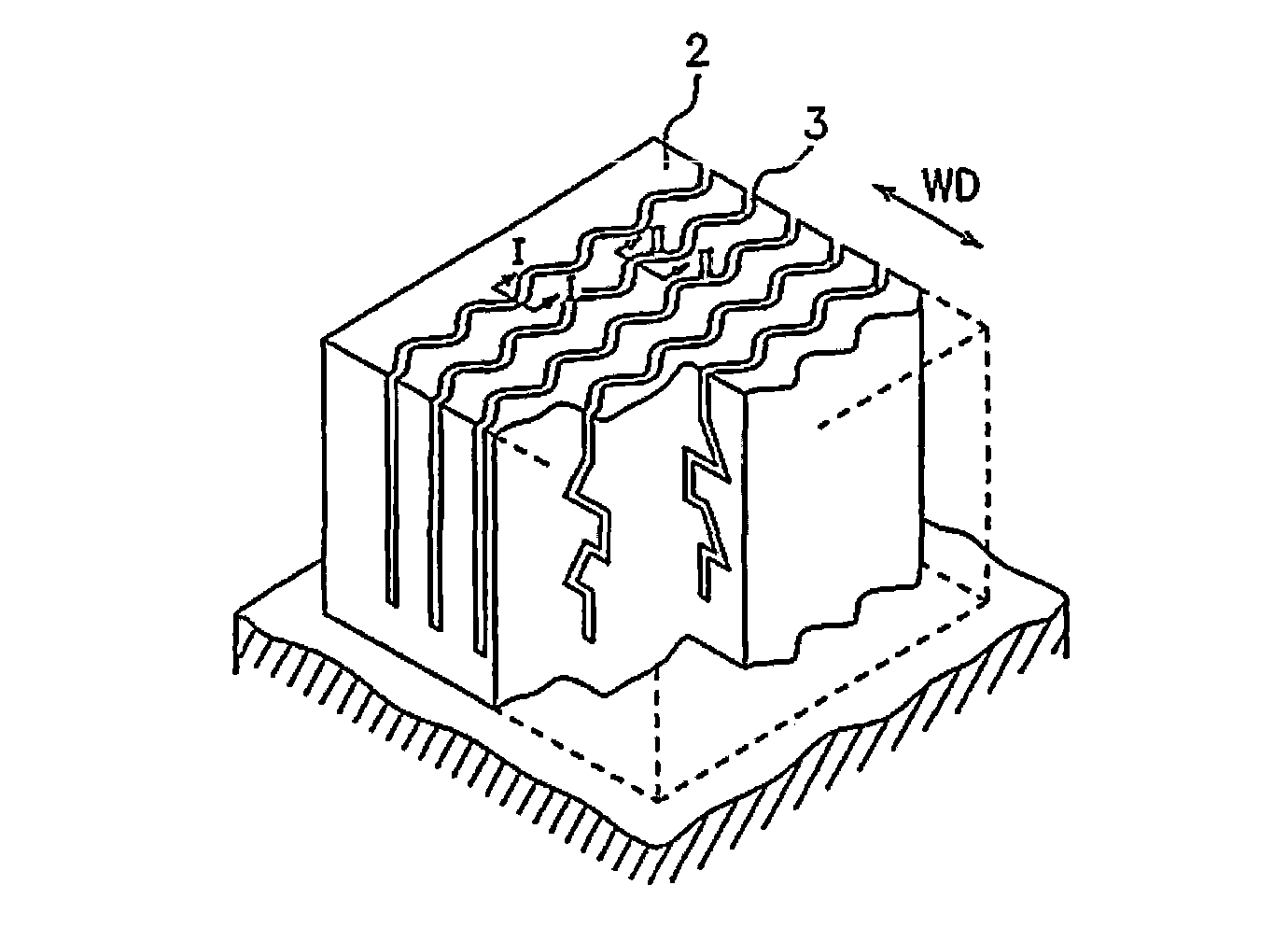

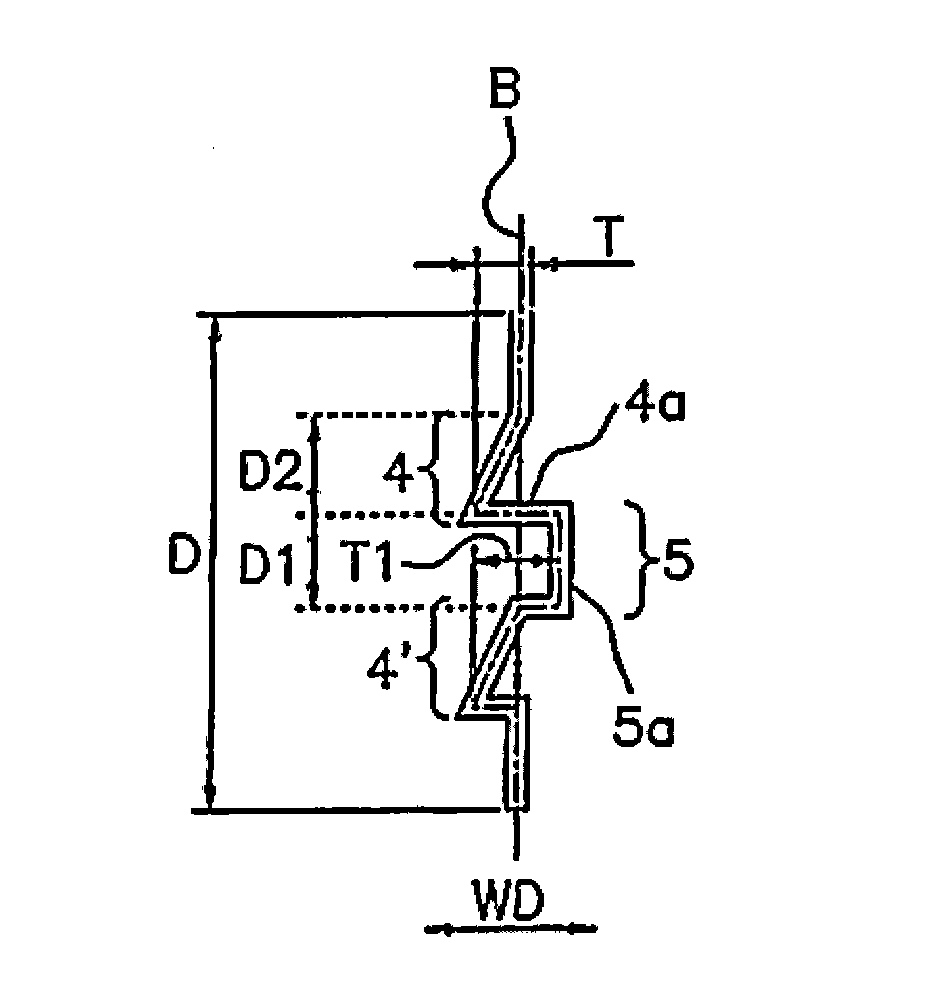

Pneumatic tire

InactiveCN101811422AReduced ground areaFully rigidTyre tread bands/patternsRoad surfaceDepth direction

An object of the present invention is to provide a pneumatic tire that ensures both of the on-ice braking performance and the dry braking performance. In order to achieve the object, a pneumatic tire comprises a tread surface (1) including a land portion in which a plurality of sipes (3) are formed, wherein each of the sipes (3) includes a reference plane (B) extending in a depth direction of the sipe from a wavy or zigzag line in the surface of the land portion and each of the sipes is formed with a convex portion having a convex shape in a vertical section with respect to the reference plane (B) in a top area at the front side and the rear side thereof. Preferably each of the sipes (3) is further formed with a concave portion (4) having a concave shape in the vertical section with respect to the reference plane in a top area at the front side and the rear side thereof. The concave portion (4) includes a flat plane portion located at the convex portion (5) side as viewed in the depth direction of the sipe extending in the width direction (WD) of the sipe, and the convex portion is connected to the flat plane portion (4a).

Owner:TOYO TIRE & RUBBER CO LTD

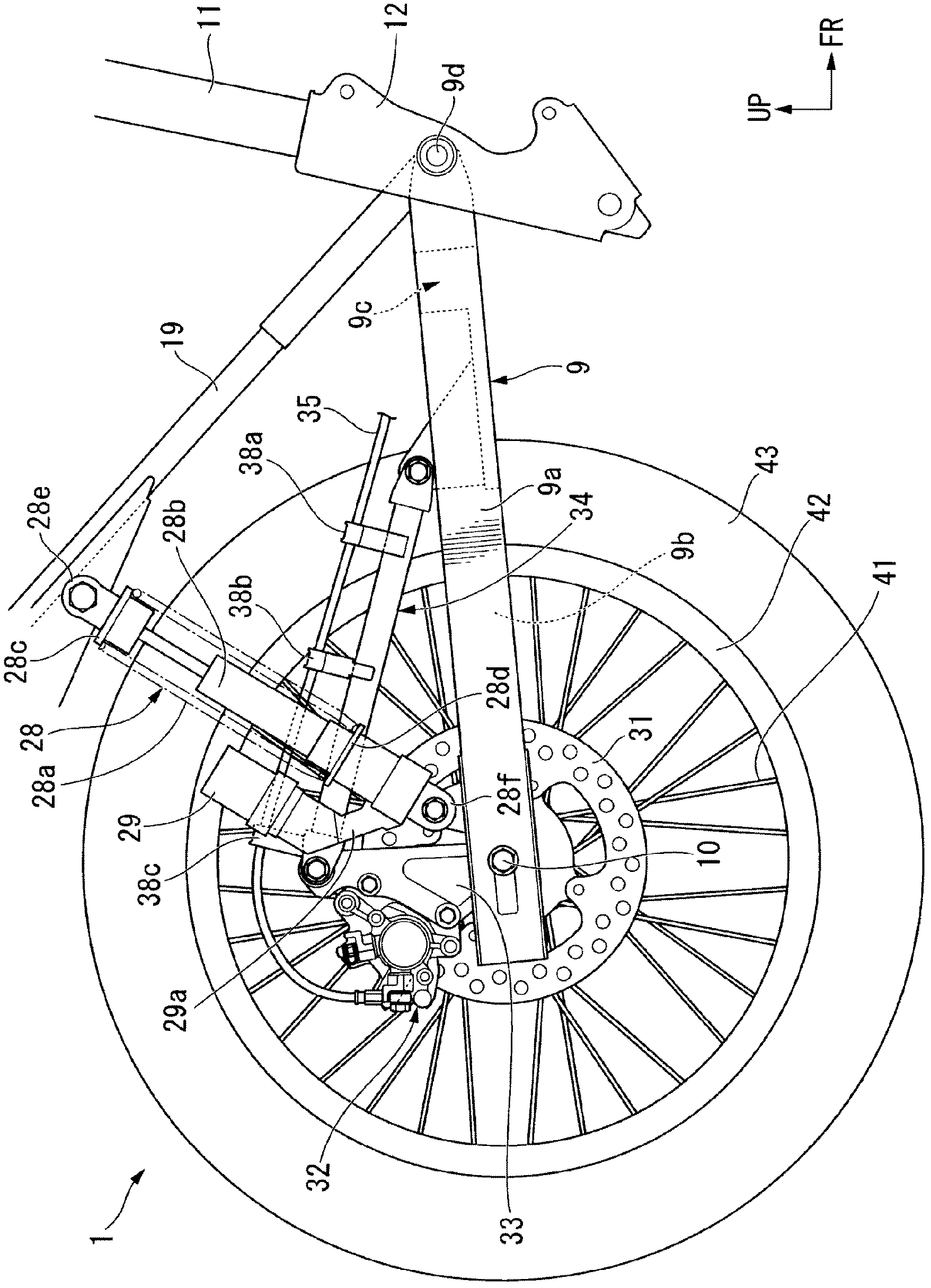

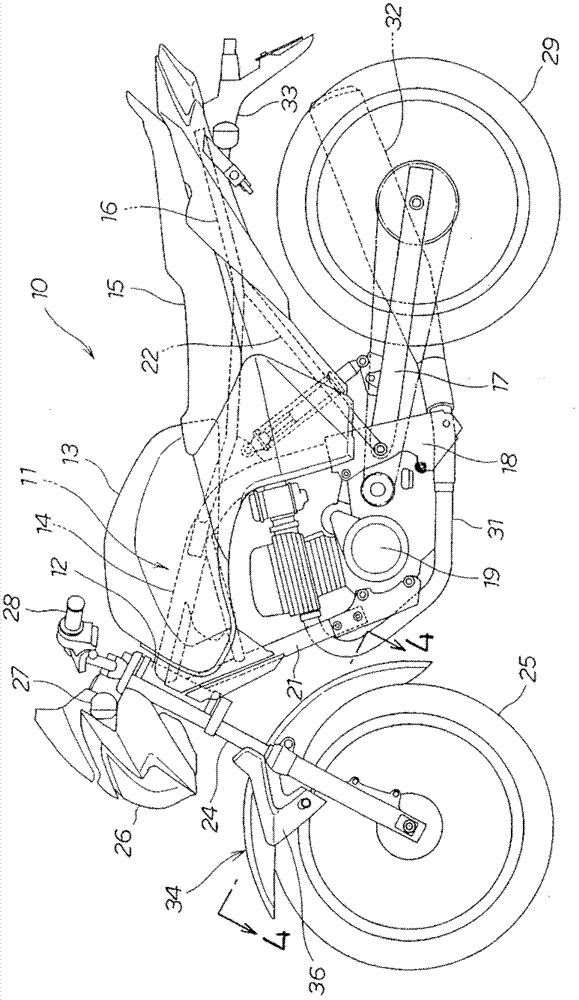

Motorcycle

Owner:HONDA MOTOR CO LTD

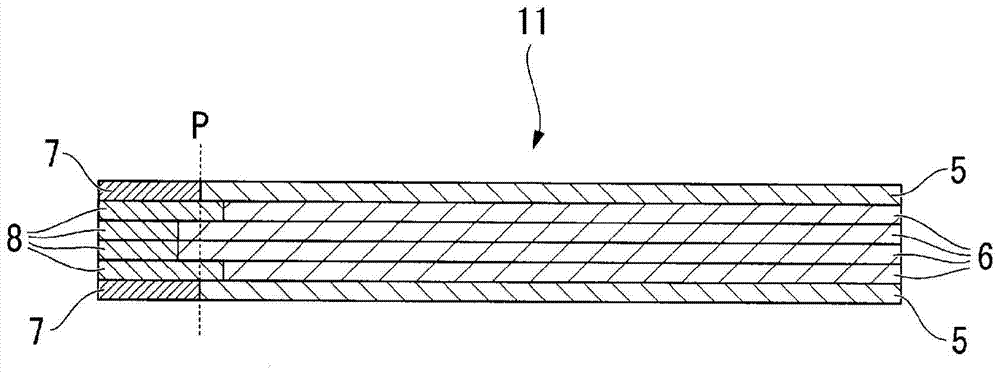

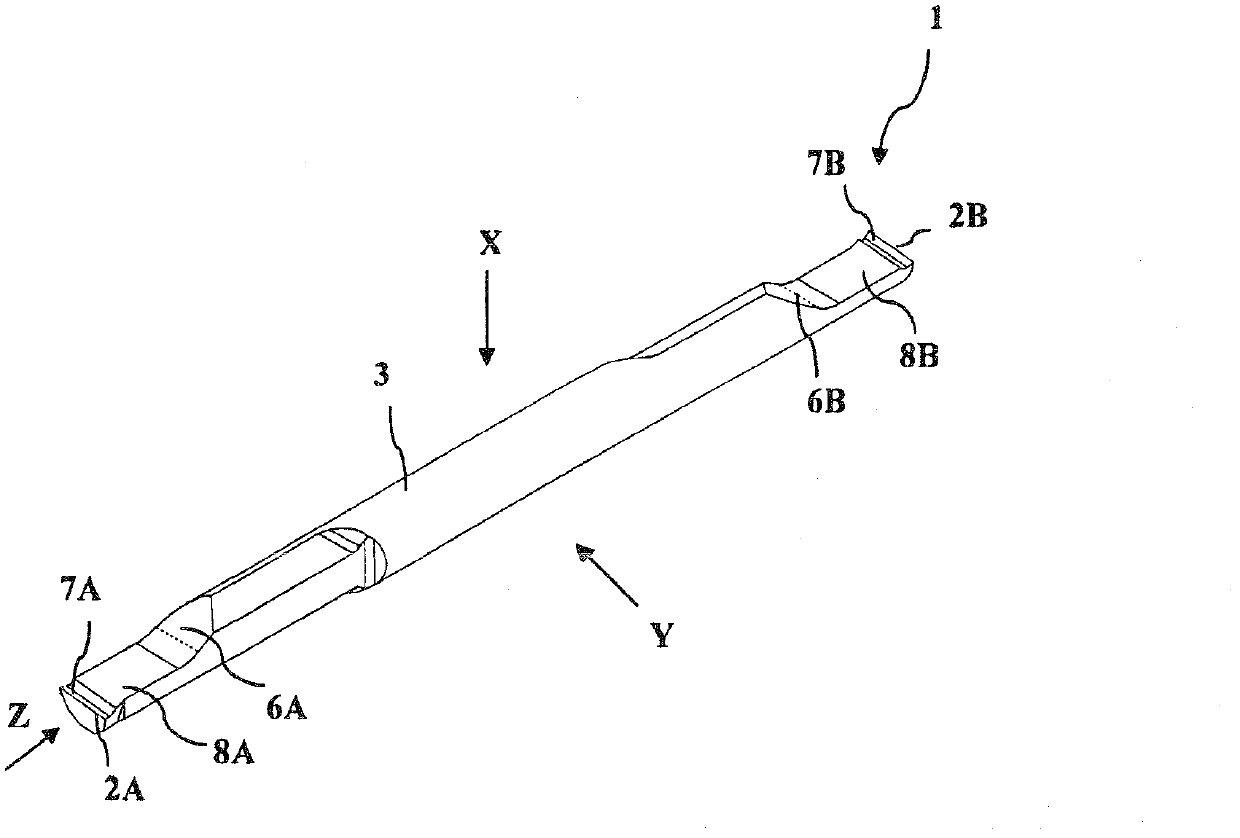

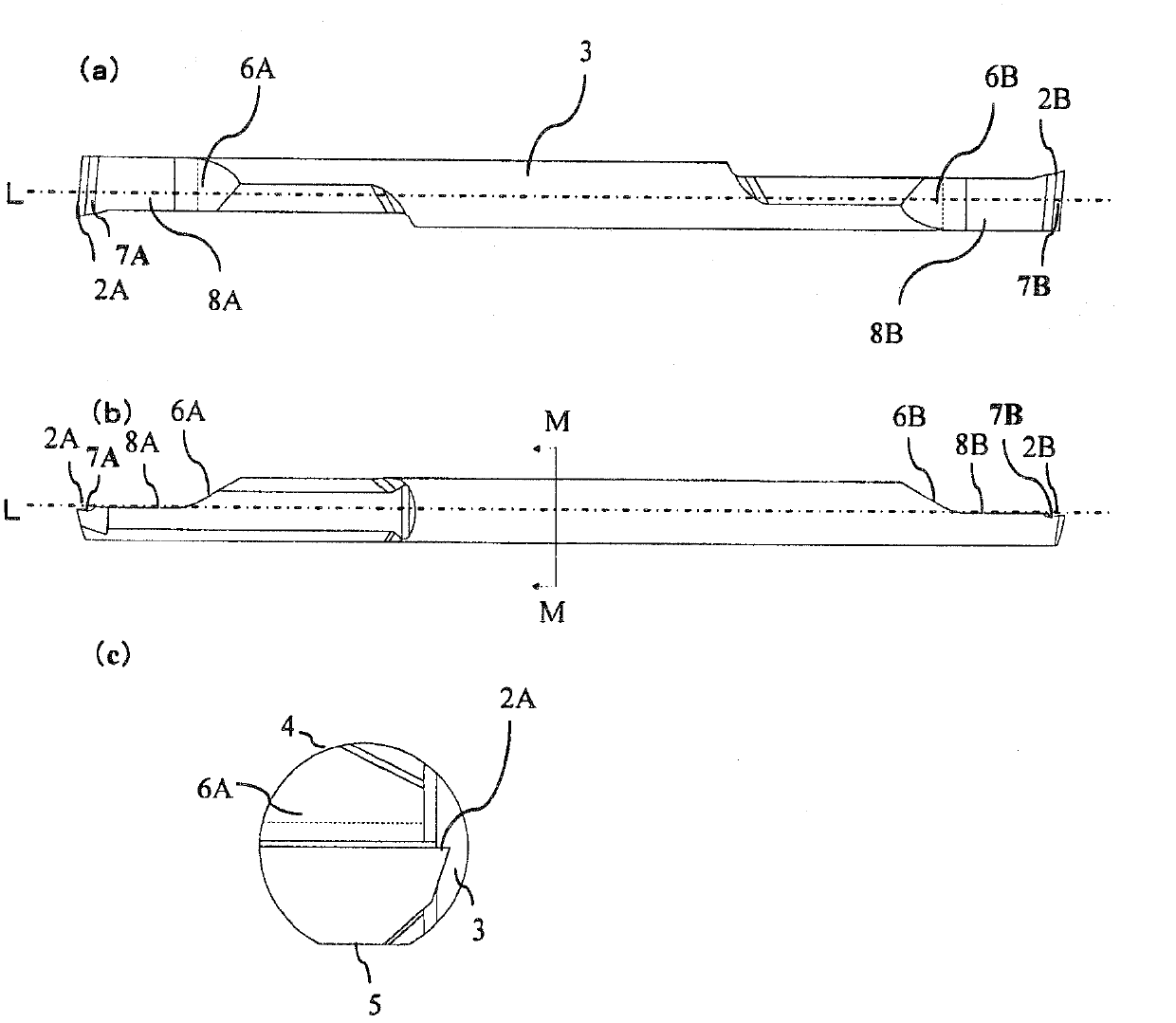

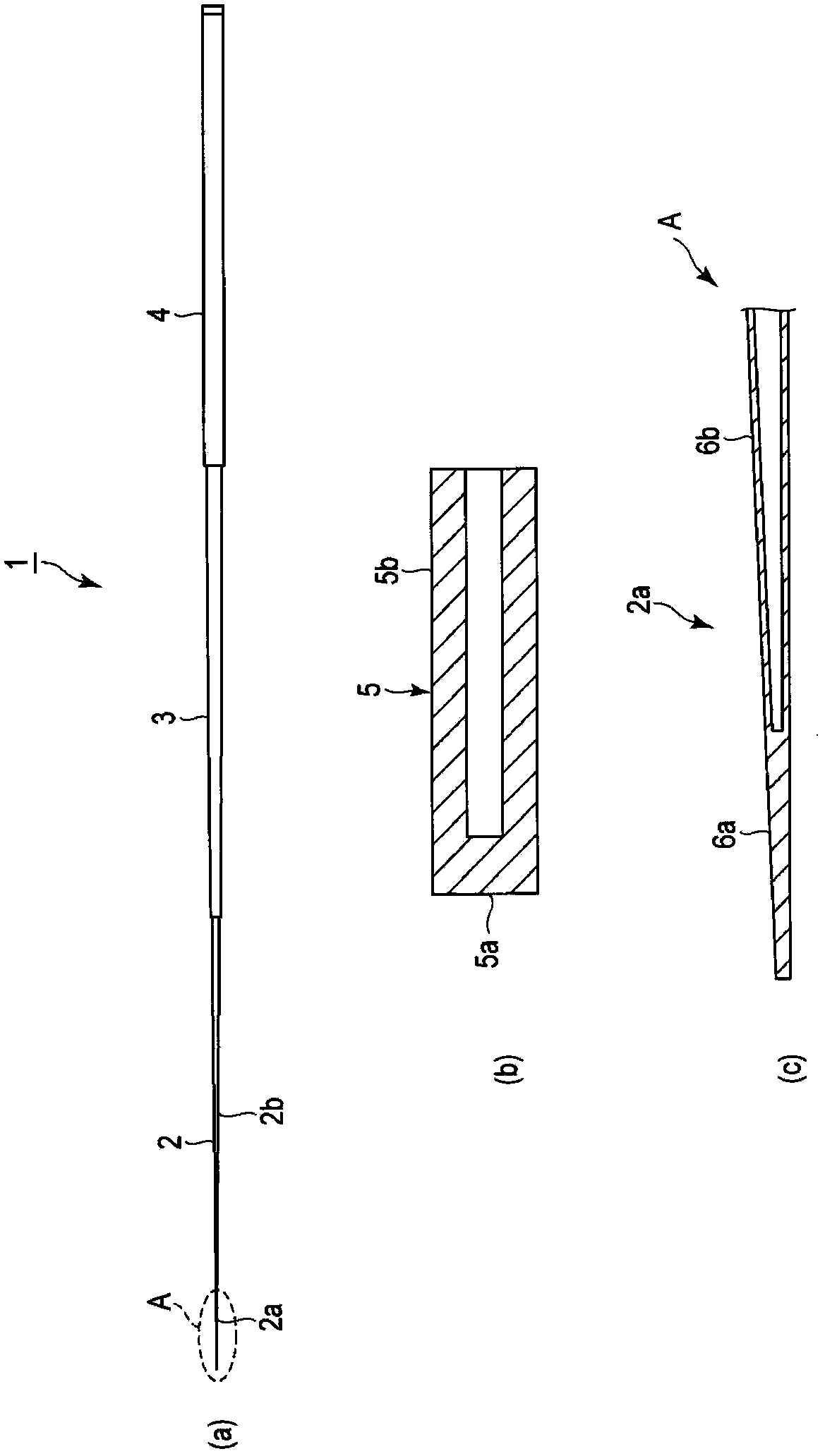

Rod tip section and fishing rod with the same

The present invention provides a tip section and a fishing rod using the tip section. The tip section is light in weight and sufficiently rigid, bends sensitively when a fish bites a hook, and has a tip that can easily distinguish a fish from taking the bait. More specifically, the rod tip section of the present invention is composed of a rod tip portion, a cylindrical tip support portion, and a joint portion. The rod tip portion is formed of a metal material and includes a solid portion of any length disposed at least on the rod tip side, The tip support portion is formed of a fiber-reinforced resin material, and the joint portion is formed of a metal material or a fiber-reinforced resin material, and joins the rod tip portion and the tip support portion.

Owner:DAIWA SEIKO CORPORATION

pneumatic tire

The rolling height HT of the carcass (4) is set to be 10 mm or less, the distance GO from the outer surface of the tire to the carcass (4) is set to be more than 50% of the total thickness GT, and the height HB of the bead filler (6) is set to be 50% to 80% of the section height SH, the cross-sectional area ratio VB / VR of the bead filler (6) to the sidewall reinforcement layer (9) is set to 0.4 to 0.6, on the other hand, for the bead filler (6) and For the side wall reinforcement layer (9), the hardness HsB is set to 65 to 80, the hardness HsR is set to 75 to 85, the relationship between the hardness HsB and the hardness HsR is set to HsB≤HsR, and the dynamic elastic modulus E'B is set to 7.0 MPa to 15.0 MPa, dynamic elastic modulus E'R to 7.0 MPa to 15.0 MPa, tan δ value TB to 0.06 and tan δ value TR to 0.05 or less. To provide a pneumatic tire capable of achieving a high balance between ride comfort during normal running and zero-pressure running durability.

Owner:THE YOKOHAMA RUBBER CO LTD

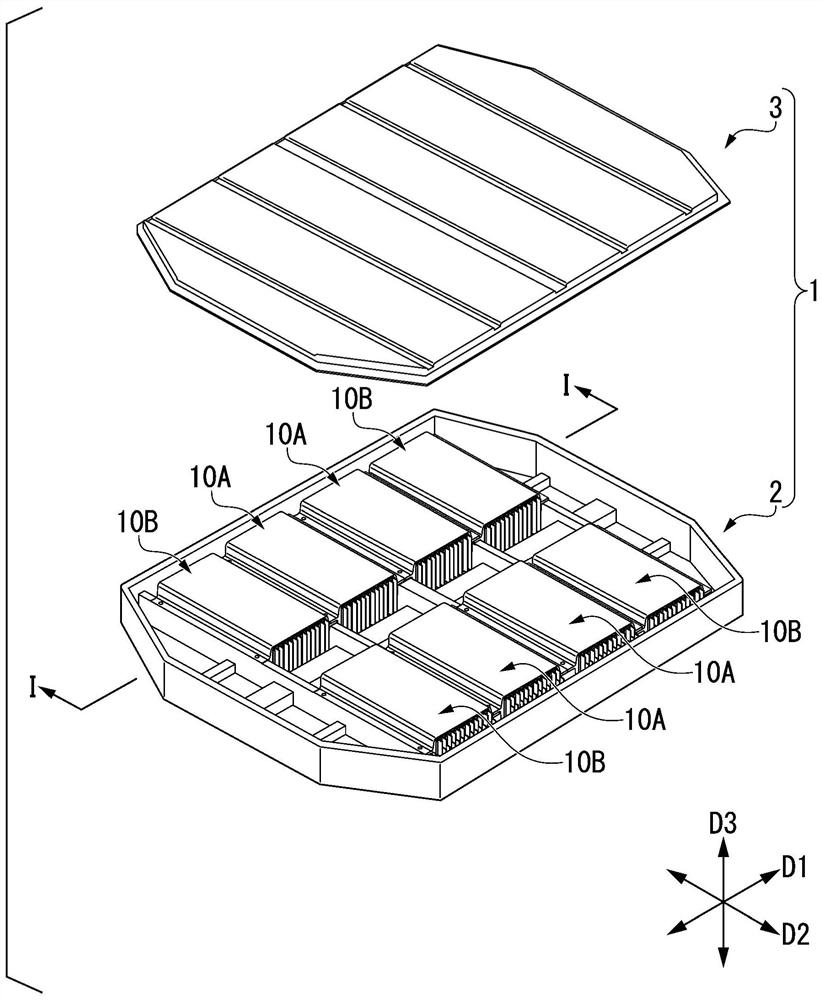

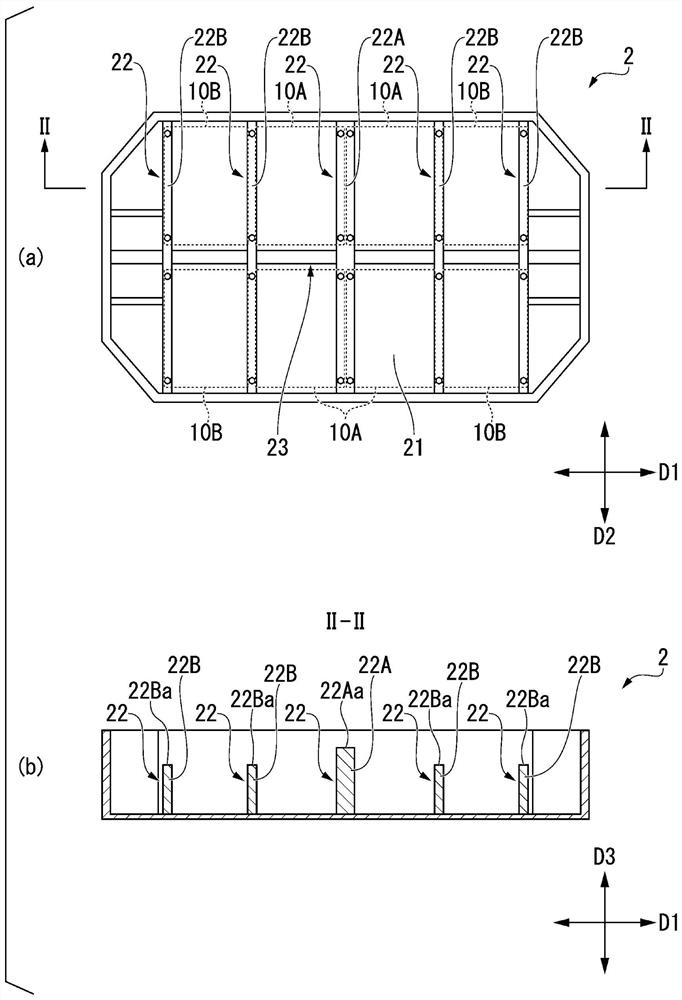

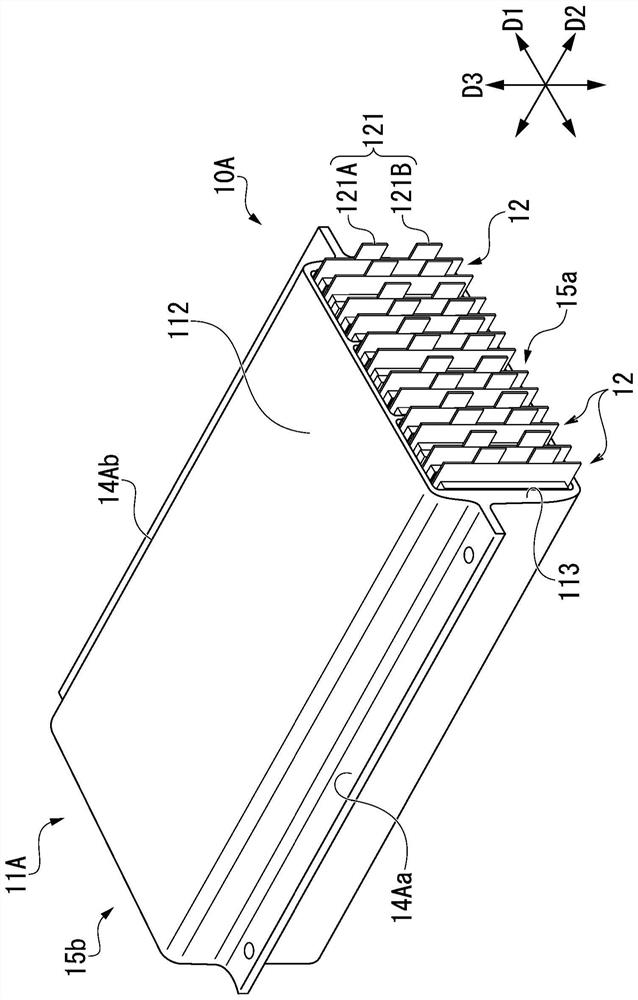

Power storage module and power storage module pack

ActiveCN112290144AFully rigidEasy to assembleAssembling battery machinesFinal product manufactureIn vehicleControl theory

Provided are a power storage module and a power storage module package which are capable of improving assemblability and improving impact resistance from below while ensuring sufficient rigidity and vehicle-mounted properties. The power storage module comprises: a frame body; a plurality of power storage cells accommodated in the frame body; a bridging portion that is provided inside the frame body and connects an upper portion and a lower portion of the frame body to each other; and two flange portions that are provided outside the frame body and project in directions opposite to each other.The two flange portions are located above a central portion of the frame body in a height direction.

Owner:HONDA MOTOR CO LTD

Device for electrical connection and circuit breaker

ActiveCN102315049BSimple designReduce volumeProtective switch terminals/connectionsProtective switch operating/release mechanismsElectricityContact pad

The device has a flat conducting part (6) fixed on a terminal pad (1) and a bimetal (2), where the part is formed from copper band. The part is formed by a conductor element continuously wound and flattened so as to provide length corresponding to a gap between a foot (2a) of bimetal and the terminal pad and a semi-rigid structure. The structure permits the deformation of the part under handling effect of an adjusting screw (7) so as to permit the displacement of bimetal while being sufficiently rigid for assuring relative positioning of the foot with respect to a contact pad.

Owner:SCHNEIDER ELECTRIC IND SAS

Image forming apparatus

InactiveCN1312540CImprove rigidityFully rigidHectographic duplicationElectrographic process apparatusEngineeringMechanical engineering

To improve the rigidity of an image forming apparatus provided with an ejection part between an image reading device and an image forming apparatus body. Since a joint cover 61 is attached to a printer body 1, and a scanner unit 81 is supported by the joint cover 61, a connection part consisting of the joint cover 61 between the printer body 1 and the scanner unit 81 is made as a paper ejecting part 99 to eject paper 3, and the front end of the side cover 63 of the joint cover 61 is arranged on the front side of the front end 82a of an original platen 82, so that a front end recess 66 recessed on a backside is formed at the front end. Thus, the ejected paper 3 is easily taken out from the recess of the front end recess 66 while supporting the scanner unit 81 by the side cover 63, and the improvement of operability is attained while securing the rigidity of the apparatus.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com