Flexible circuit substrate

A flexible circuit substrate, anisotropic technology, applied in the direction of circuit, printed circuit components, printed circuit structural connection, etc., can solve the problems of warpage, undulation, operation obstacles and other problems of flexible circuit substrate, and achieve the effect of good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

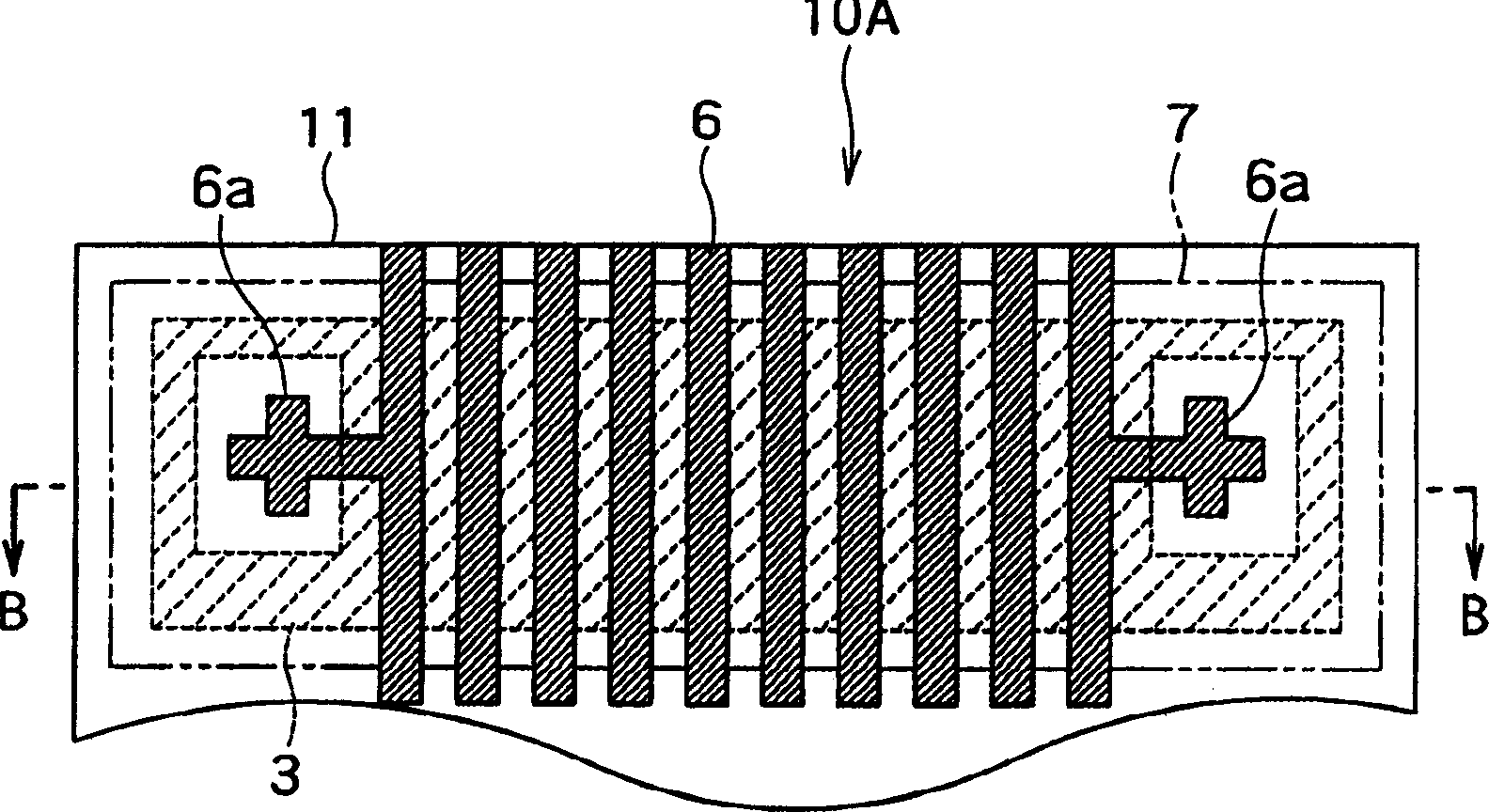

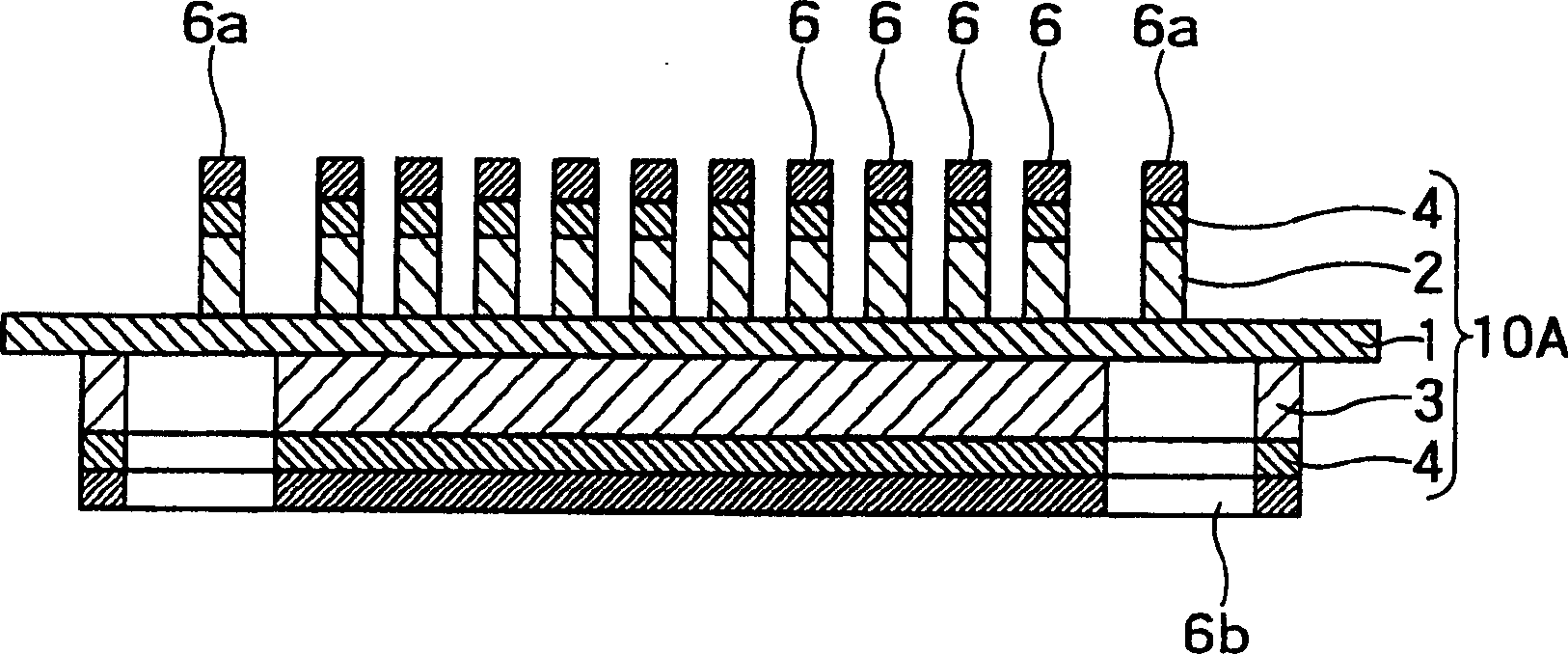

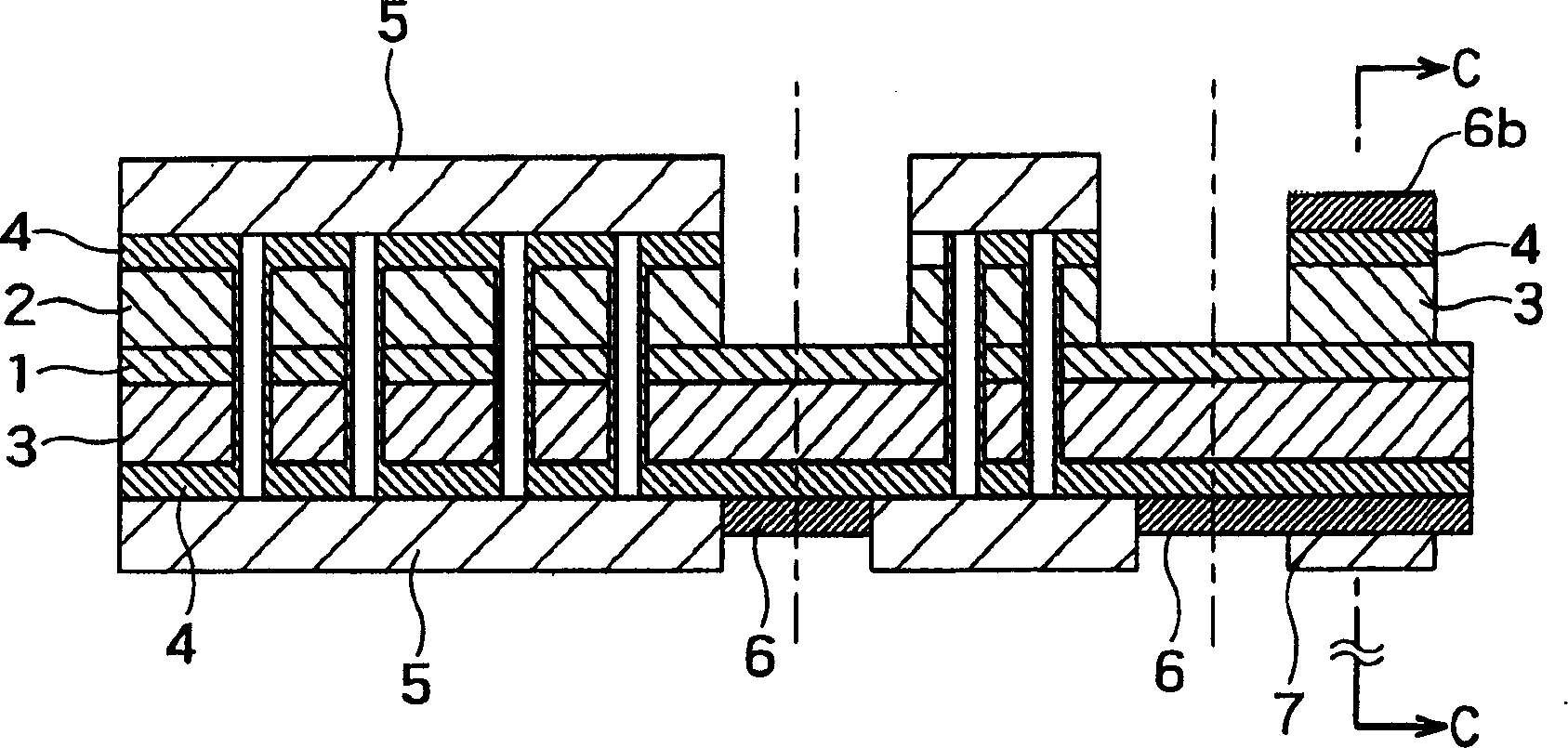

[0026] figure 1 It is a plan view of Embodiment 1 of the present invention, showing an end portion of a flexible circuit board provided with a connection terminal connected to a target device such as a display panel. exist figure 1 In the center of , 12 surface treatment layers (terminals) 6 are arranged at equal intervals along the longitudinal direction in the figure, and marks 6a extend from the left and right outermost terminals 6 .

[0027] Then, on the circuit board 10A, the anisotropic conductive resin layer 7 is formed on a region extending from the outer edge 11 of the board including the terminals 6 and the marks 6a to a little inside. For this reason, the filling amount of the anisotropic conductive resin must be appropriate and cannot be used too much.

[0028] In addition, in figure 1 In the diagram, the back rough wiring layer 3 on the back side of the circuit board 10A is indicated by dotted lines (contours) and hatched lines (copper foil). The outer edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com