Molded fiber-reinforced composite material and manufacturing method therefor

A composite material, fiber-reinforced technology, applied in shielding materials, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as thickening of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

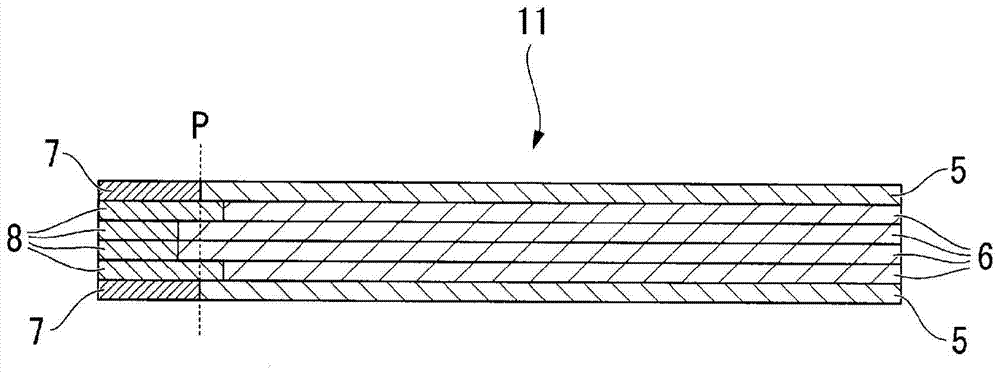

[0080] in order to achieve image 3 The fiber-reinforced composite material molded body shown is a 0° direction formed by joining carbon fiber prepreg (unidirectional material) in the 0° direction and glass fiber prepreg (unidirectional material) in the 0° direction in the extending direction The prepreg joint sheet of the 90° direction is formed by joining the carbon fiber prepreg (unidirectional material) in the 90° direction and the glass fiber prepreg (unidirectional material) in the 90° direction in the extending direction. A bonded sheet was used, and a laminate in which six layers of the bonded sheet were laminated in the order [90° / 0° / 0° / 0° / 0° / 90°] was produced. At this time, the junction (junction line) between the carbon fiber prepreg and the glass fiber prepreg is as follows: image 3 In this way, each of them is shifted by 10mm from the joining center P. In addition, a glass fiber prepreg is arranged at one end. Next, the prepreg was pressed at a pressure of 3 M...

Embodiment 2

[0082] The position of the bonding line between carbon fiber prepreg and glass fiber prepreg is as follows: Figure 4 Except for such changes, it was carried out in the same manner as in Example 1 to obtain a thin plate-shaped fiber-reinforced composite material molded body 21 with a thickness of 0.60 mm.

Embodiment 3

[0084] From the structure of Example 1, the glass fiber prepreg of the outermost layer is changed from a unidirectional material to a fabric material, and the joining positions other than the outermost layer are changed, thereby obtaining Figure 5 Such a fiber-reinforced composite material molded body 31 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com