Polypropylene molded article, sheet-like polypropylene molded article, and method for production of polypropylene thermally molded article

A manufacturing method and technology of polypropylene, applied in the direction of flat products, applications, household appliances, etc., can solve the problems of difficulty in satisfying rigidity and transparency, difficulty in obtaining molded products, and high dimensional accuracy, and achieve transparency, cost reduction, and thickness The effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、4、5、7、8、9

[0208] Examples 1, 4, 5, 7, 8, 9 (based on the melt extrusion flow rapid cooling condition A of the test machine)

[0209] Specifically, under the conditions described below, an extrusion step using a screw-type single-screw extruder was implemented.

[0210] ·Screw: Full thread type, compression ratio of 3.5, 65mmФ

[0211] ·Screw speed: 70rpm (the discharge rate is about 45kg / hour constant)

[0212] ·T mold: coat hanger type (width 800mm, mold lip opening 1.5mm)

[0213] ·Extrusion temperature: 240℃

[0214] ·Extrusion speed (V 0 ): 0.57m per minute

[0215] ·Air gap (La): 150mm

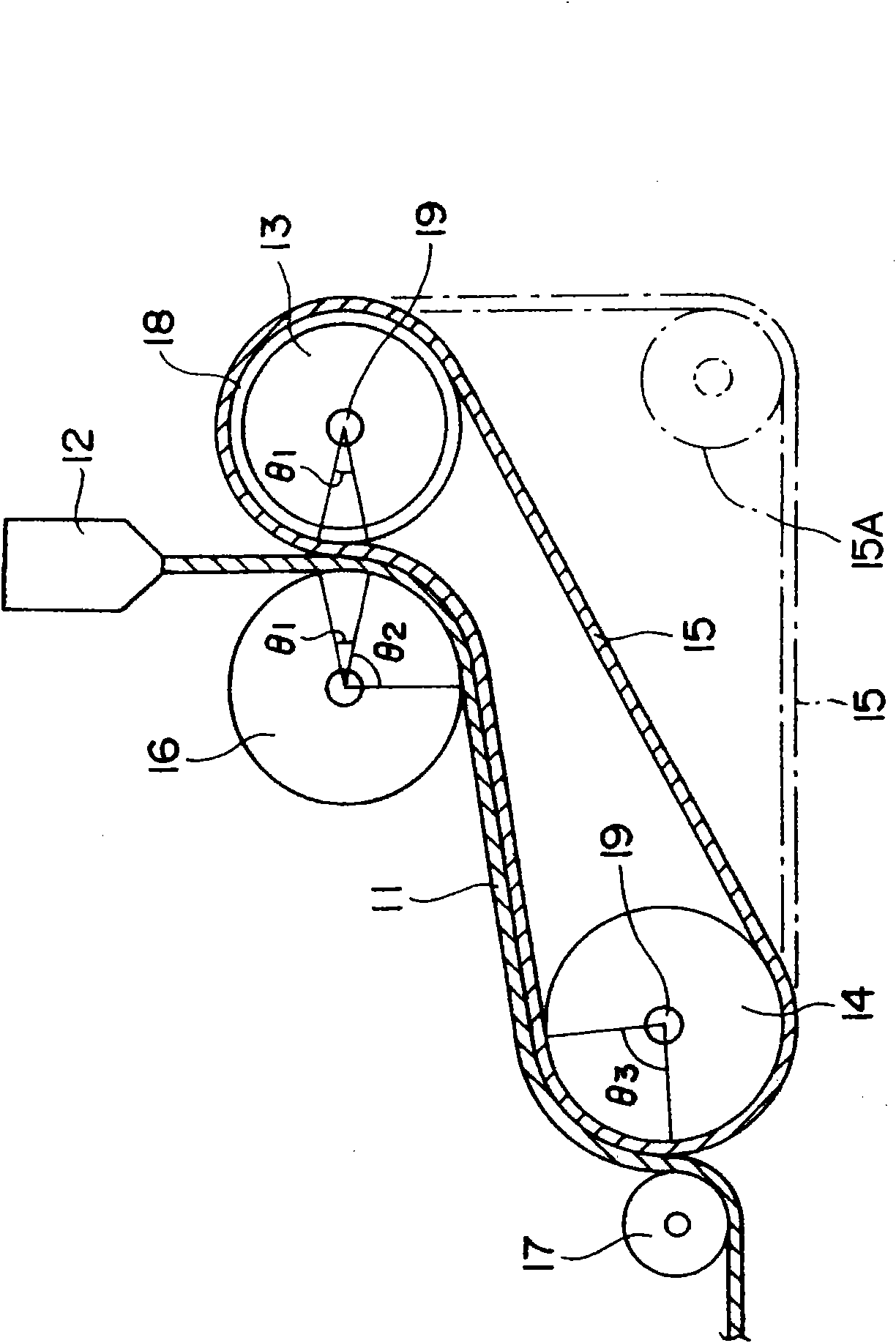

[0216] The cooling process including the metal belt and the metal roll is the conditions described below.

[0217] ·Temperature: 20℃

[0218] ·Roller diameter: 270mmФ

[0219] ·Roll angle with contact part: 50°

[0220] Here, the angle of the roller with contact part is based on Japanese Patent Laid-Open No. 9-136346 figure 1 The sum of θ1 and θ2 disclosed in.

[0221] ·Pulling speed (V): (1.2 / t)m / min

[0222] Here, ...

Embodiment 2、3、6、10、11、14、15、16

[0226] Examples 2, 3, 6, 10, 11, 14, 15, 16 (using the melt extrusion flow rapid cooling condition B of the testing machine)

[0227] Specifically, under the conditions described below, an extrusion step using a screw-type single-screw extruder was implemented.

[0228] ·Screw: Full thread type, compression ratio of 3.5, 65mmФ

[0229] ·Screw speed: 125rpm (discharge rate: about 80kg / hour)

[0230] ·T mold: clothes hanger type (width 800mm, mold lip opening 2.0mm)

[0231] ·Extrusion temperature; 240℃

[0232] ·Extrusion speed (V 0 ): 1.2m per minute

[0233] ·Air gap (La): 150mm

[0234] The cooling process including the metal belt and the opposing metal roll is the conditions described below.

[0235] ·Temperature: 20℃

[0236] ·Roller diameter: 270mmФ

[0237] ·Roll angle with contact part: 50°

[0238] ·Pulling speed (V): (2.1 / t)m / min

[0239] Here, t represents the sheet thickness (mm).

[0240] ·Cooling time: 0.68[sec]×t / 0.1

[0241] Here, the cooling time is obtained by dividing the circum...

Embodiment 12、13

[0242] Example 12, 13 (Using the melt extrusion flow rapid cooling condition C of commercial equipment)

[0243] Specifically, under the conditions described below, an extrusion step using a screw-type single-screw extruder was implemented.

[0244] ·Screw: Full thread type, compression ratio of 3.5, 65mmФ

[0245] ·Screw speed: 86rpm (about 540kg / hour)

[0246] ·T mold: clothes hanger type (width 1100mm, mold lip opening 1.5mm)

[0247] ·Extrusion temperature: 240℃

[0248] ·Extrusion speed (V 0 ): 6.1m per minute

[0249] ·Air gap (La): 150mm

[0250] The cooling process including the metal belt and the opposing metal roll is the conditions described below.

[0251] ·Temperature: 18℃

[0252] ·Roller diameter: 600mmФ

[0253] ·Roll angle with contact part: 50°

[0254] ·Average pulling speed: (9.0 / t)m / min

[0255] Here, t represents the sheet thickness (mm).

[0256] ·Cooling time: 0.367[sec]×t / 0.1

[0257] Here, t represents the sheet thickness (mm).

[0258] (Heat treatment process)

[0259] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com