Ice melting system for overhead contact system of electric railway

A technology for electrified railways and catenaries, applied in the direction of overhead lines, etc., can solve the problems of large device loss, complicated operation, inability to realize online control and dynamic switching, and achieve the effect of increasing force rate and real-time compensation of reactive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

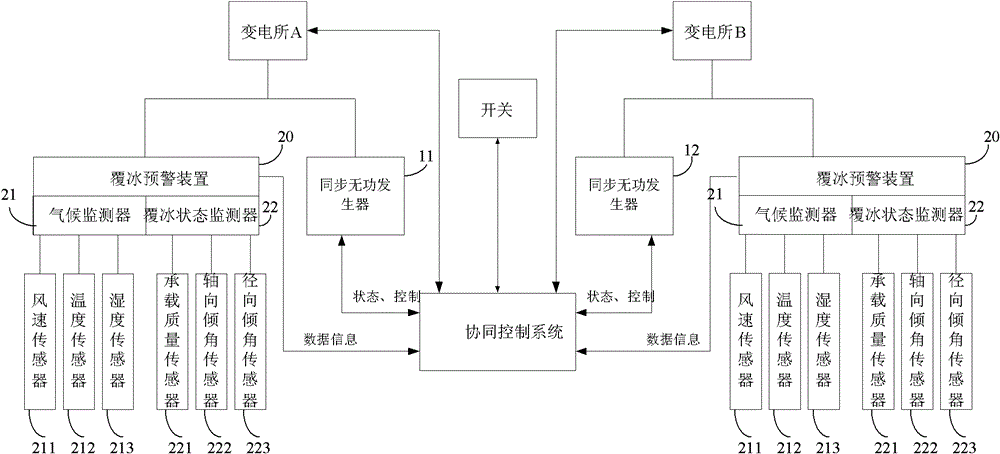

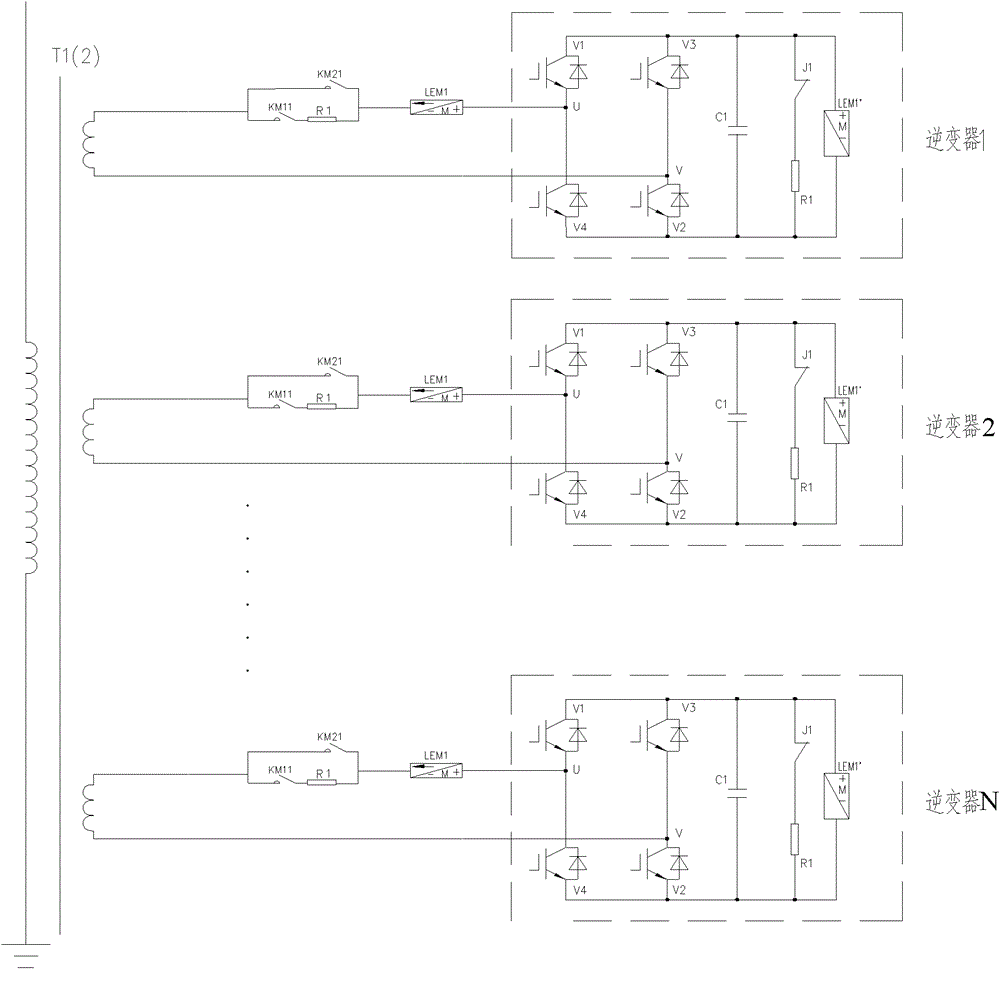

[0023] In the present invention, synchronous var generators (SVG) are respectively arranged on the adjacent power supply arms of the two substations of the contact network. The power generator generates an equal amount of capacitive reactive power-Q, so that reactive current flows from the power supply arm, generating Joule heat to achieve the effect of melting ice.

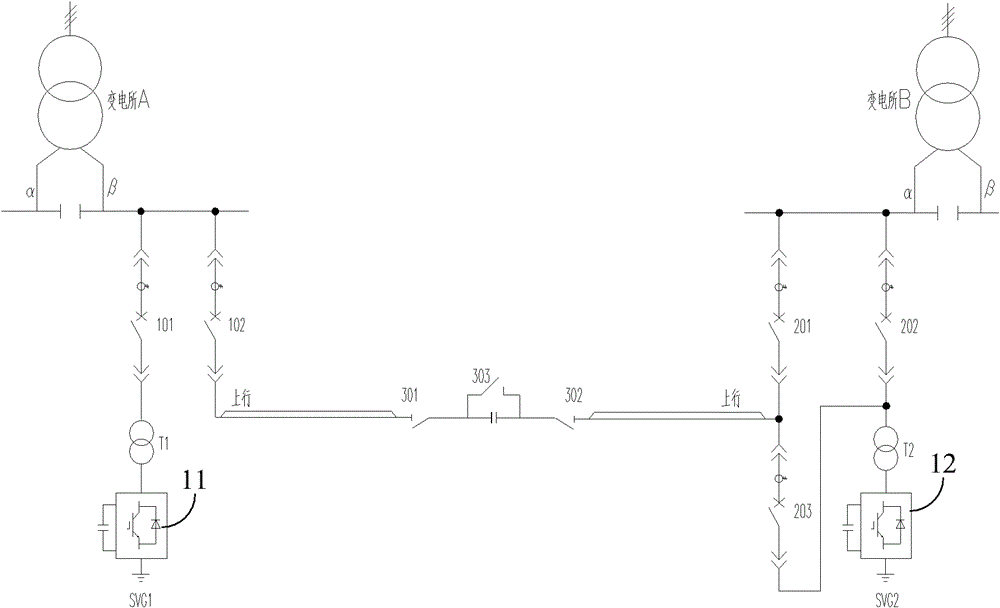

[0024] see figure 1 , showing the structure of the electrified railway catenary ice melting system. A synchronous var generator 11 and a synchronous var generator 12 are respectively installed on the β supply arm of the traction substation A and the α supply arm of the traction substation B. The synchronous var generator 11 is connected to the β power supply arm th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com