Multi-curved surface diaphragm protective plate

A technology of sheet protective film and multi-curved surface, applied in the field of multi-curved diaphragm protective film, can solve the problems of reduced displacement accuracy, easy damage of composite diaphragm, etc., to reduce elastic deformation, prolong life, and reduce sliding friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

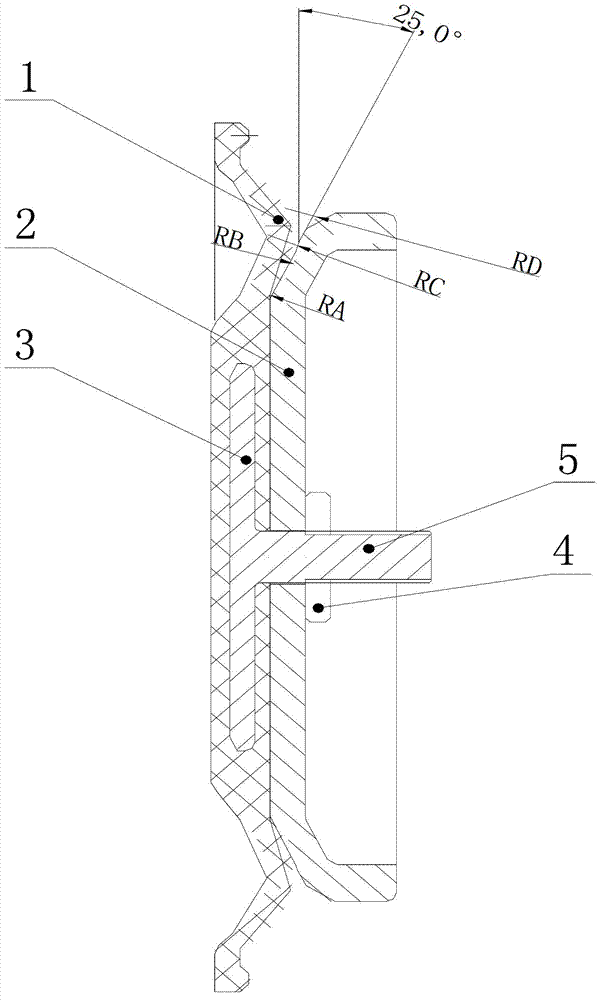

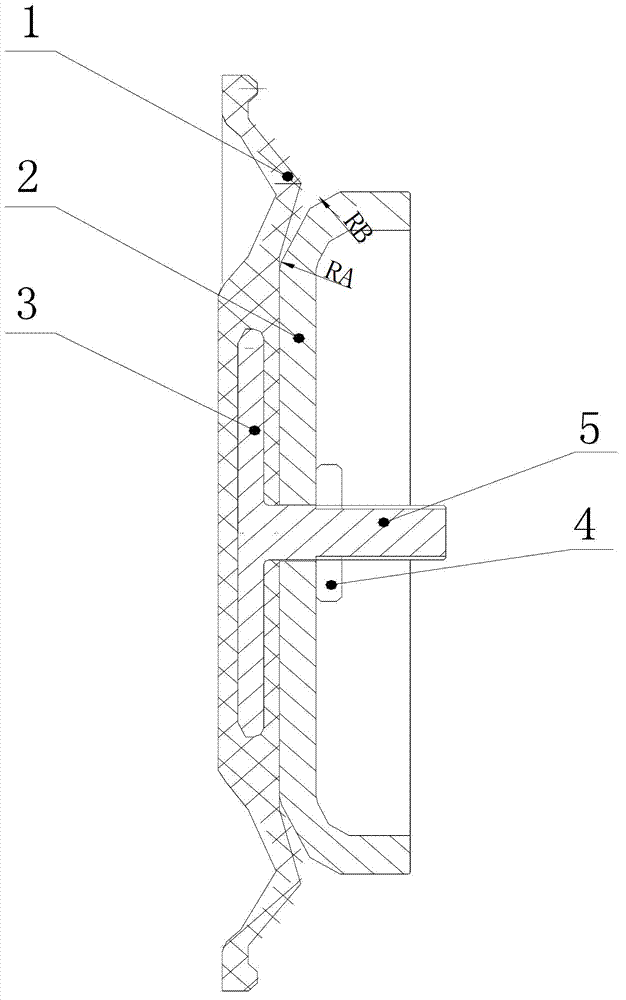

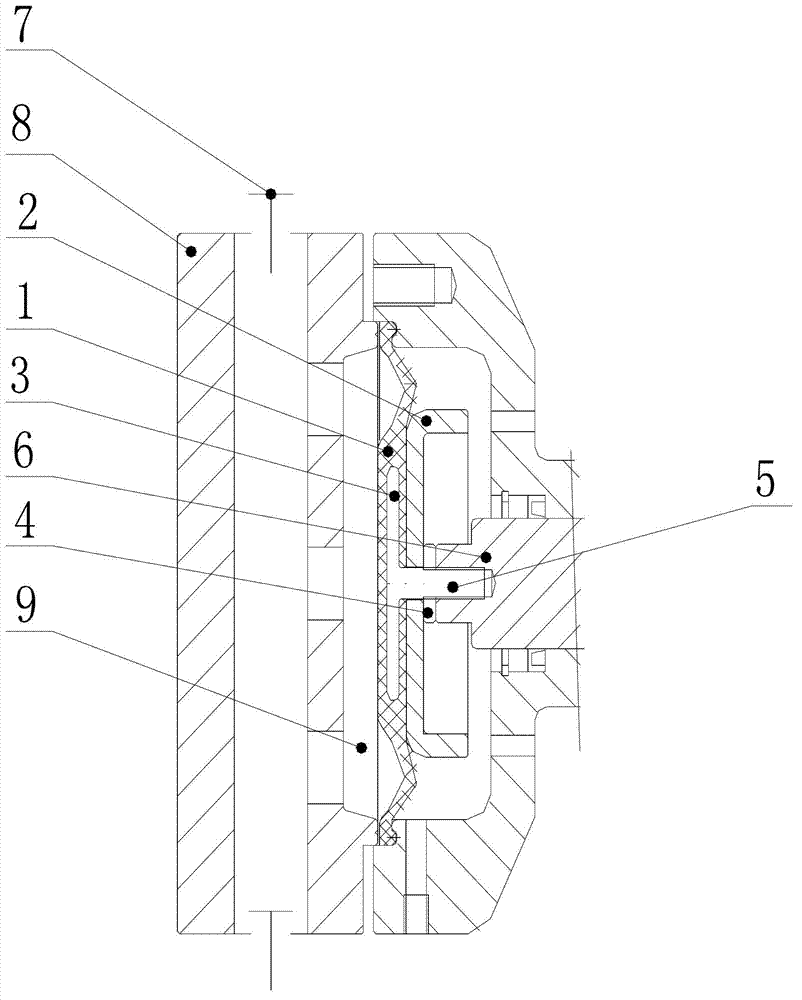

[0024] figure 1 Among them, the multi-curved membrane sheet pellicle plate includes a membrane supporting plate 2 that works in cooperation with the composite membrane 1, and the composite membrane 1 and the membrane supporting plate 2 have opposite planar parts, and the composite membrane 1 is in contact with the membrane There are convex curved surface parts at the junctions of the edges of the film supporting plate 2 , and the edges of the diaphragm supporting plate 2 have a concave curved surface structure matched with the convex curved surface parts of the composite diaphragm 1 . The surface curvature of the concave curved surface structure on the edge of the diaphragm supporting plate 2 is 44° to 47°, and the concave curved surface can effectively reduce the elastic deformation of the composite diaphragm 1, so that the gap between the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com