Temperature control valve made of shape memory alloy material

A technology of valves and valve plates, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as valve closure, and achieve the effects of simple structure, obvious shape changes, excellent stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

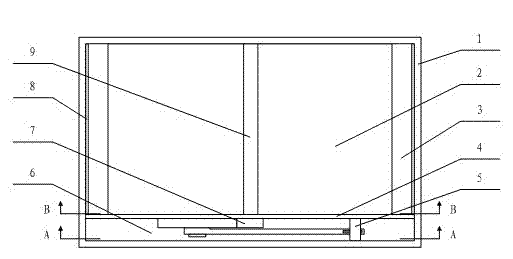

[0014] figure 1 It is a top view of the overall structure of the present invention, showing the open state of the valve, communicating with the inside and outside.

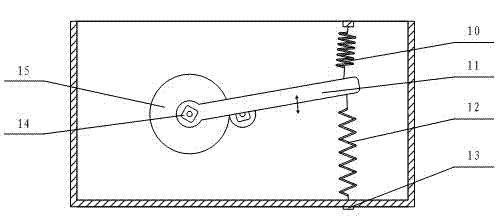

[0015] figure 2 for figure 1 The A-A sectional view shows the working condition of the control room when the valve is open, the SMA spring is contracted and tightened, and the return spring is stretched and stressed.

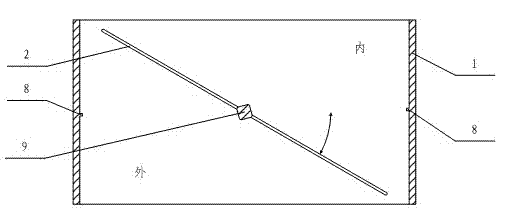

[0016] image 3 for figure 1 The B-B sectional view of the valve shows the working condition of the valve chamber when the valve is open. The valve plate is rotated and opened under the force of the SMA spring, and the inside and outside are connected to realize heat exchange. The word "inside" marked in the figure is connected with the controlled area, and the word "outside" marked is connected with the external environment.

[0017] Such as Figure 1-3 As shown, the present invention regulates and controls the temperature valve, which includes a case shell 1, a valve plate 2, a partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com