Method for monitoring dynamic fractures of underground mining working face

A working face and fracture technology, which is applied in the field of monitoring dynamic fractures at the front end of the well mining working face in the sandstorm area, can solve the problems of high fluidity, inability to obtain the life cycle of front end fractures, and difficulty in identifying and selecting observation objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

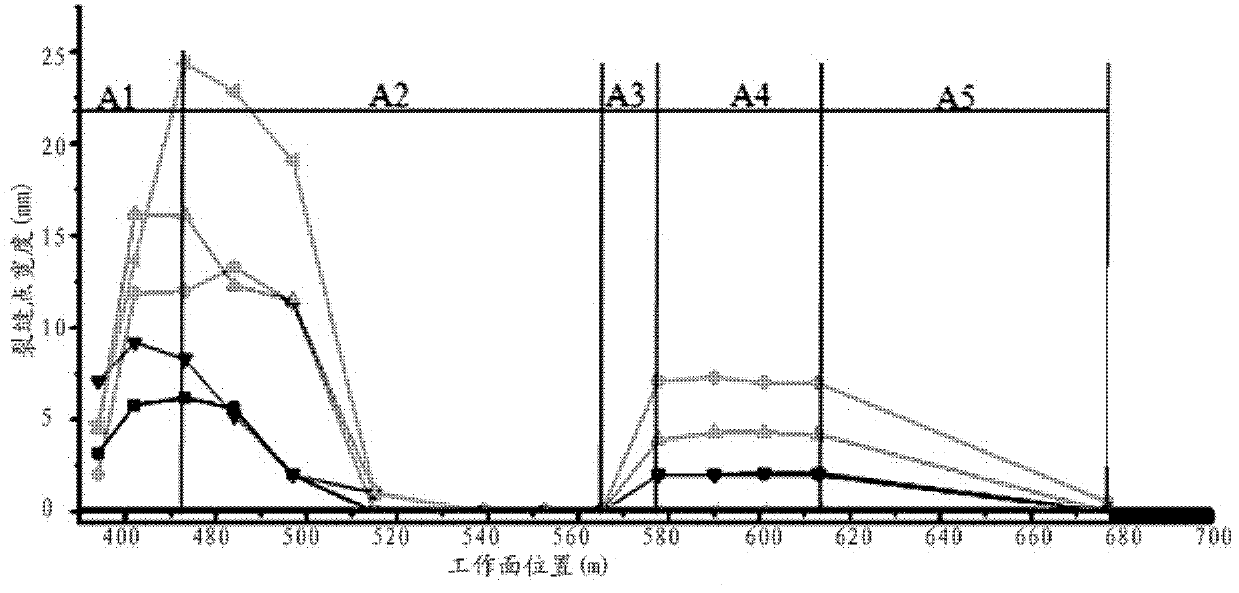

[0050] Embodiment: Aiming at the monitoring of mining cracks in a certain mining area, the crack width information obtained by the above method is used to draw a trend diagram of the crack width advancing with the working face, as shown in image 3 As shown, there are 5 observation points on the crack, where ■ represents 1#, ● represents 2#, ▲ represents 3#, Represents 4# and Represents 5#.

[0051] When the front working face is 454m away from the cutting hole, the crack appears first, 7m ahead of the working face; when the working face advances 19m, the crack shows the largest sign, and the 5# information collection point increases from 3.3mm to about 25mm, The change speed is about 1.158mm / m. This area corresponds to the A1 stage. In this stage, the fracture widths of the four information collection points #1, #2, #3, and #4 are all increasing, which belongs to the fracture development stage.

[0052] When the working face continued to move forward for 42m, the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com