High-voltage transformer with epoxy shielding barrel and manufacturing method thereof

A technology of high-voltage transformers and shielding cylinders, which is applied in the direction of transformer/inductor cores, inductors/transformers/magnets, transformers, etc., and can solve the problems of high production costs of voltage transformers, long-term storage of products, and few transformer applications, etc. problems, to achieve the effect of optimizing electric field distribution, convenient storage, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

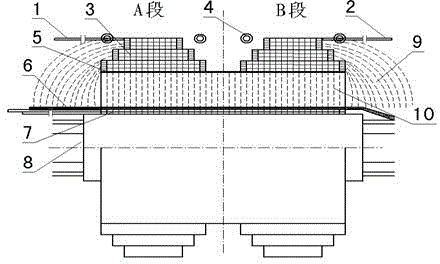

[0015] Such as figure 1 , the primary winding is divided into two sections A and B, and there are high-voltage incoming terminal A-terminal 1 and high-voltage outgoing terminal B-terminal 2 respectively on them. The electric field distribution inside the entire transformer is uneven, and similar shielding measures must be taken. For example, adding a voltage equalizing ring 4 to improve the electric field at the end of the transformer, etc., and the only thing that can approximate a parallel electric field inside the transformer is the electric field 10 between the epoxy shielding tube 5 of the primary winding and the shielding paper 6 of the secondary winding. The shielding cylinder 5 can effectively make the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com