Method for replacing the ropes of an elevator, and an elevator

A rope and elevator technology, applied in the field of elevator rope replacement and elevator, can solve problems such as discomfort, separate hoist and other auxiliary devices, and achieve the effect of saving logistics, shortening replacement time, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

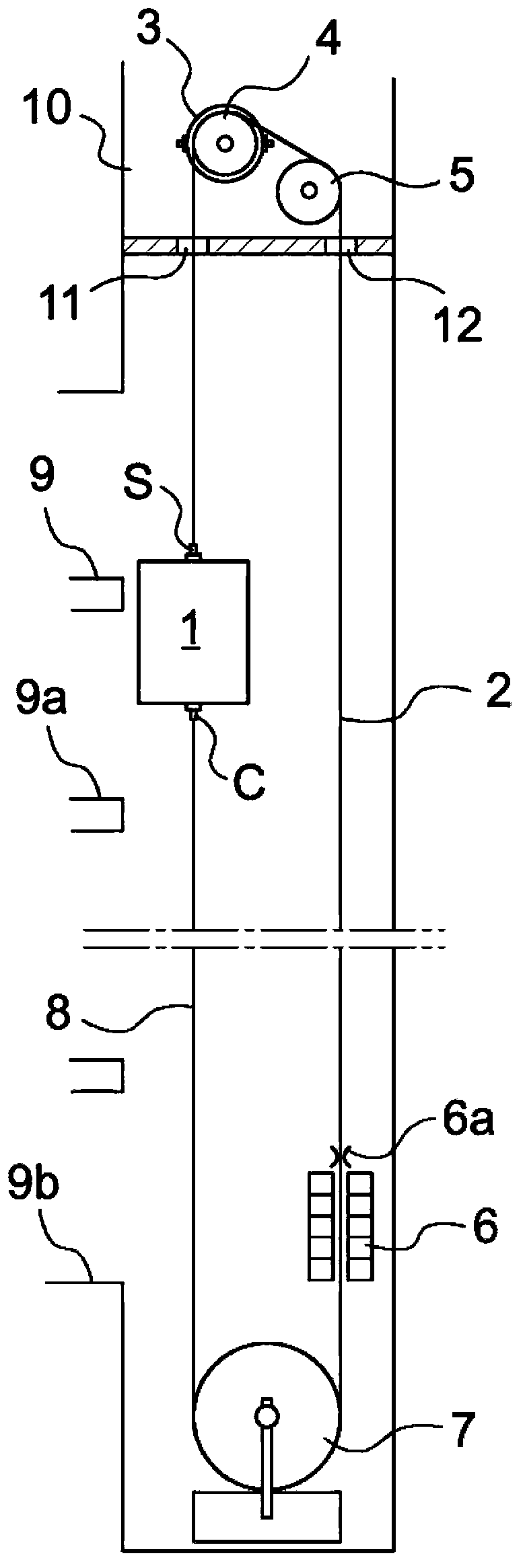

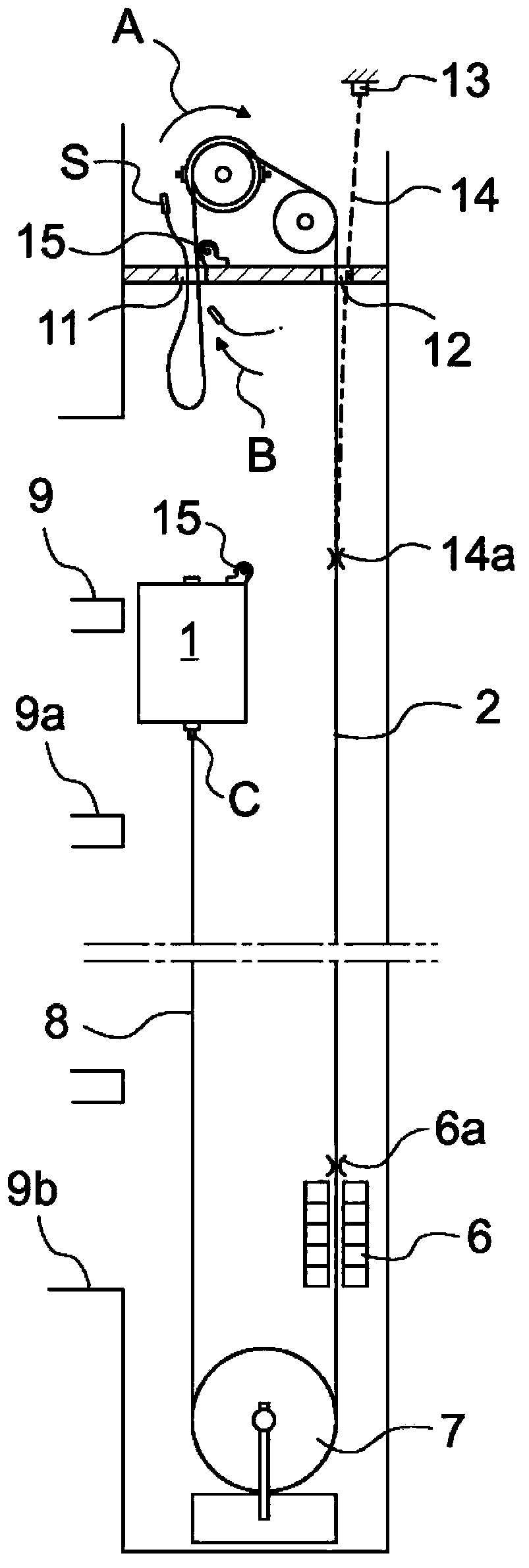

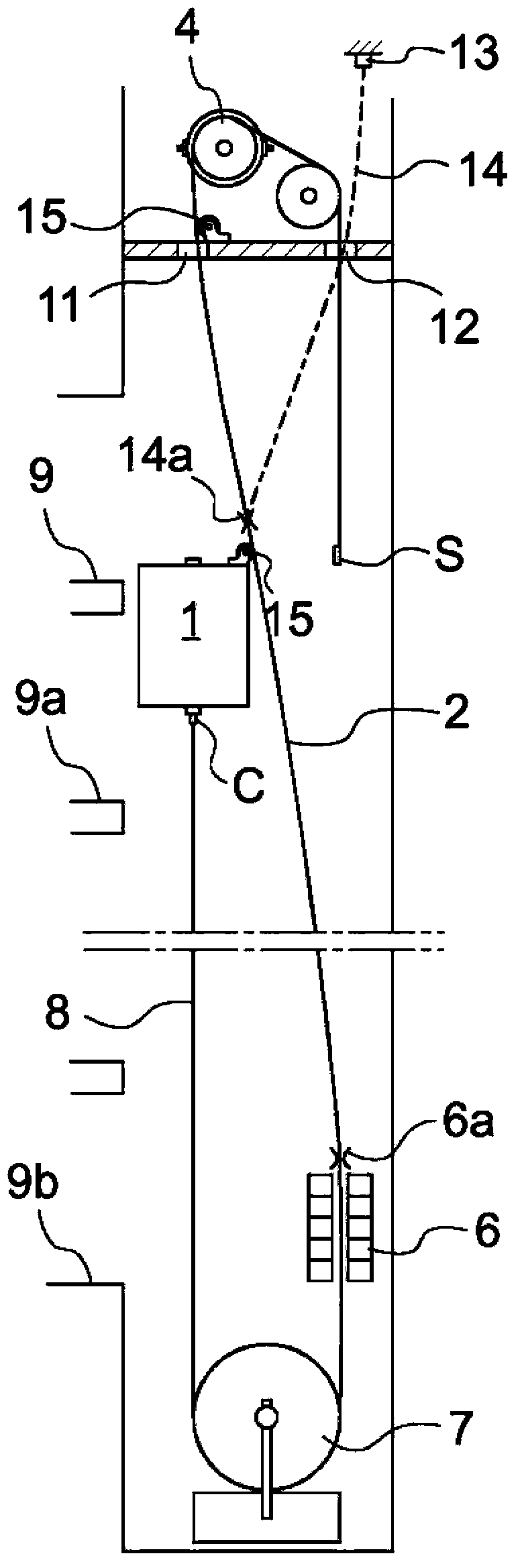

[0019] For clarity, the trailing cables are not drawn as visible in these figures. The following equations apply between the unit masses expressed in kg / m for hoisting ropes, trailing cables and compensating ropes of elevators:

[0020] m S = M C +0.25×M TC

[0021] where M S = unit mass of hoisting rope

[0022] m C = Unit mass of compensation rope

[0023] m TC = unit mass of the trailing cable

[0024] In the case represented by the above equation, the compensation of the rope is exactly 100%. In practice, however, there is sufficient accuracy when the compensation is, for example, between 97-102%.

[0025] Correspondingly, with the aid of the unit mass of the hoisting ropes and the trailing cable, the limit value A of the unit mass of the hoisting ropes for different numbers n of ropes can be calculated. The following equations are valid for calculations:

[0026] ((n-1)×M S +0.25×M TC ) / n×M S =A=0.97–1.02

[0027] From the above it follows that:

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com