Limestone slagging steelmaking lance position control method for basic oxygen furnaces

A technology of oxygen top blowing and control method, applied in the direction of manufacturing converters, etc., can solve the problems of increasing the danger and workload of furnace work, unable to further improve dephosphorization efficiency, waste of useful slag, etc. The effect of increasing the CO ratio and suppressing slag spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

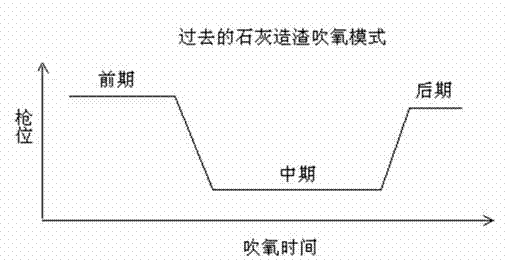

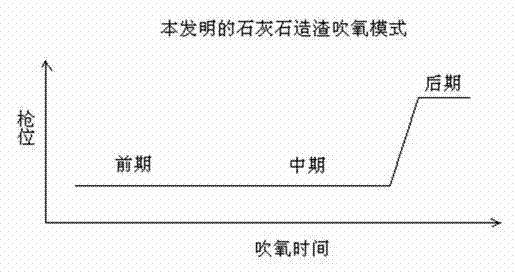

Method used

Image

Examples

Embodiment 1

[0019] On a converter with a steel tapping capacity of 60 tons, all limestone and all molten iron are used for steelmaking. The temperature of molten iron entering the furnace is 1296°C. Limestone is added in an amount of 90kg / t steel. Blow oxygen at the hard blowing position in the carbon stage, and then adjust the gun position up and down appropriately according to the splashing situation. The oxygen gun position is within the range of H=(24-30)d. After 13 minutes of oxygen blowing, lower the gun to the end of blowing At the lowest position, continue to blow oxygen for 20 seconds, then turn the furnace back to measure the temperature and take samples. The temperature reaches 1654°C. The carbon, phosphorus, and sulfur meet the composition requirements, and then the steel is tapped.

Embodiment 2

[0021] On a converter with a tapping capacity of 60 tons, the slagging material is all limestone, and the metal material is 95% molten iron + 5% scrap steel. At the beginning, lower the oxygen lance to the hard blowing position in the decarburization period for oxygen blowing, and then adjust the lance position up and down appropriately according to the splashing situation. The oxygen lance position is within the range of H=(22-28)d, blowing After 10.5 minutes of oxygen, lift the lance to the soft blowing position in the later stage of blowing, continue blowing oxygen for 1 minute and lower the oxygen lance to the lowest position for 15 seconds before the end point, then turn the furnace back to measure the temperature and take samples. The temperature reaches 1642 °C, carbon, phosphorus, sulfur Meet the composition requirements, and then tap the steel.

Embodiment 3

[0023] On a converter with a tapping capacity of 60 tons, 50% of the slagging material is lime, and the rest is added with limestone according to the CaO requirement. The metal material is 85% molten iron + 15% pig iron block. The equivalent lime is added according to the amount of 50kg / t steel. From the beginning of blowing, the oxygen lance is lowered to the hard blowing position in the decarburization period for oxygen blowing, and then the position of the lance is adjusted up and down according to the situation of splashing. Lance position H=(26~32)d range, after blowing oxygen for 10 minutes, lift the gun to the soft blowing position in the later stage of blowing, continue to blow oxygen for 1 minute and lower the oxygen gun to the lowest position for 20 seconds before the end point, then turn down the furnace Temperature measurement and sampling, the temperature reaches 1638°C, carbon, phosphorus and sulfur meet the composition requirements, and then the steel is tapped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com