Color register process for wheel hub

A wheel hub and color registration technology, which is applied in the direction of electrolytic coating, electrophoretic plating, and the device for coating liquid on the surface, etc., can solve problems such as the inability to make patterns, achieve good promotion and application value, and solve technical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of wheel hub coloring process, comprises the following steps successively,

[0024] (1) Surface treatment: pre-treatment after rough grinding of the hub blank, including degreasing-water-washing-surface conditioning-chromating-water-washing-drying, in the drying step, the temperature is 120°C, and the chain speed is 25 rpm;

[0025] (2) Powder spray body: The thickness of the powder spray body is 100um, the curing temperature is 180°C, and the chain speed is 29 rpm;

[0026] (3) The hub is ground flat, and the place with high powder spraying is ground off;

[0027] (4) Painting: firstly carry out secondary pretreatment, including degreasing-surface conditioning-washing-drying, then spray color paint with a thickness of 40um and a curing temperature of 175℃; and then spray clear paint with a thickness of 15um and a curing temperature of 175°C, the chain speed is 29 rpm;

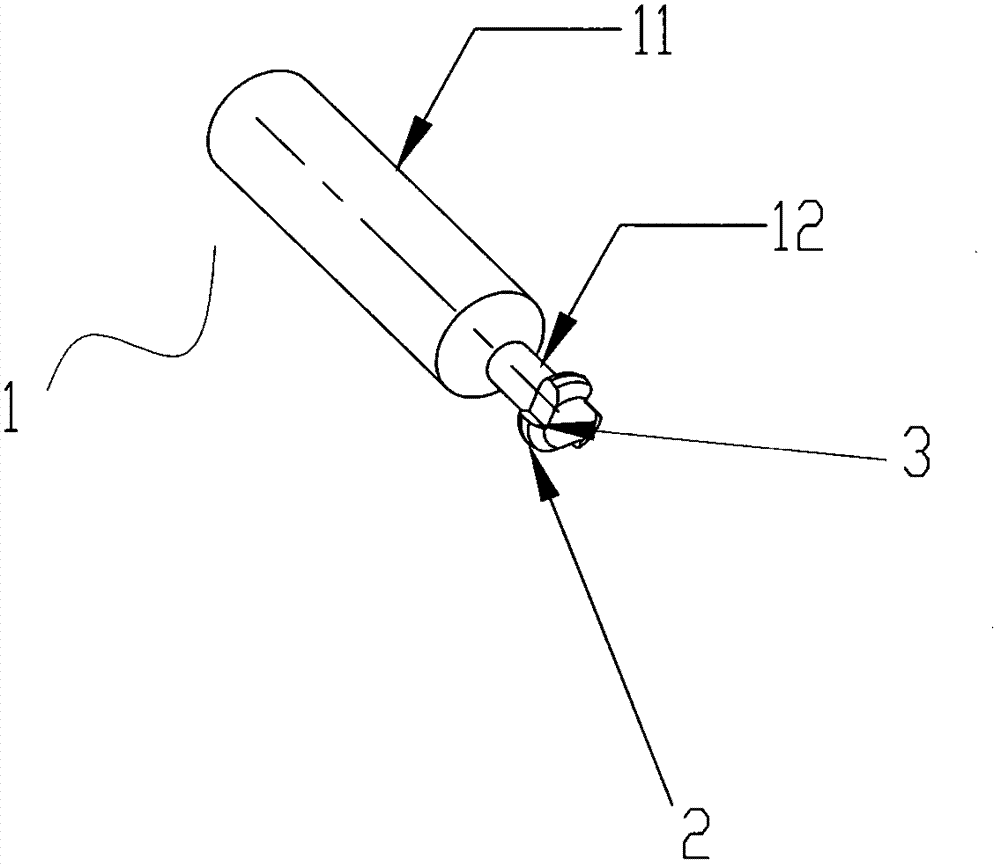

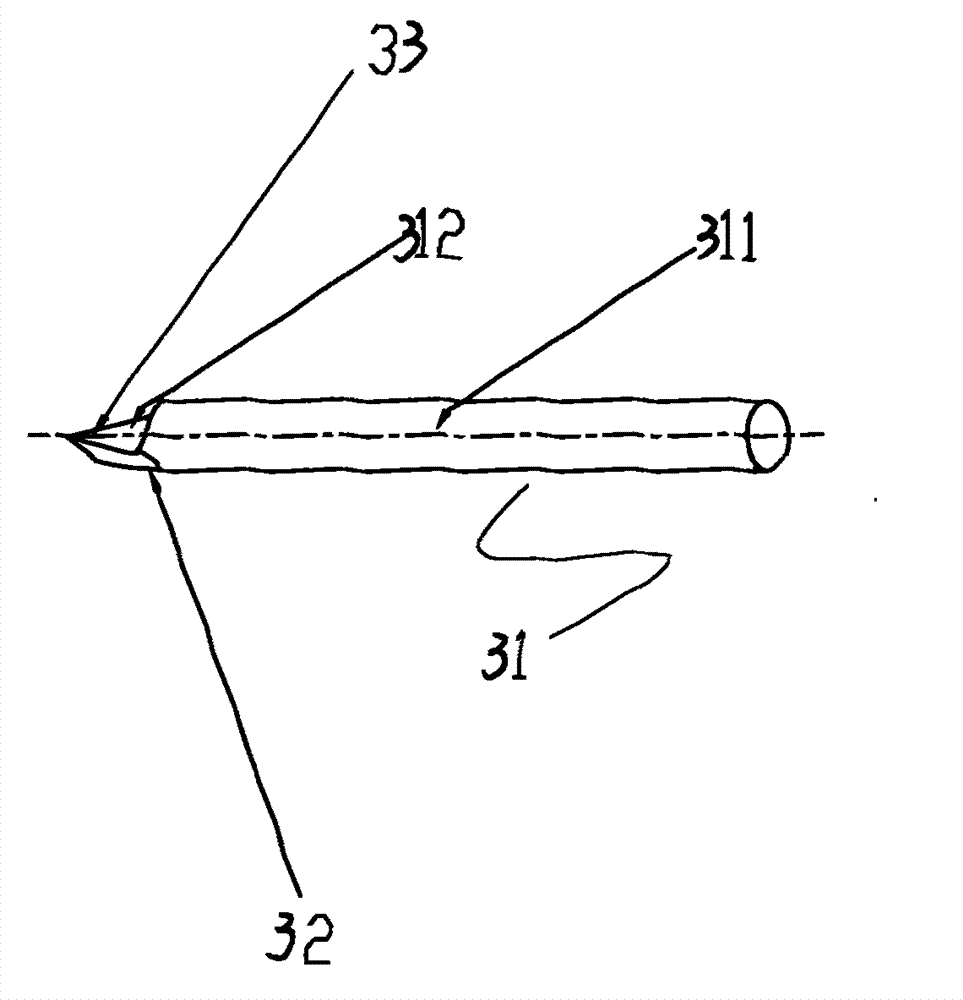

[0028] (5) Tool processing: Use the wheel hub auxiliary processing tool to pr...

Embodiment 2

[0032] A coloring process for wheel hubs comprises the following steps in turn:

[0033] (1) Surface treatment: pre-treatment is performed after rough grinding of the hub blank, including degreasing-water washing-surface conditioning-chromating-water washing-drying. In the drying step, the temperature is 160°C, and the chain speed is 35 rpm;

[0034] (2) Powder spray body: The thickness of the powder spray body is 200um, the curing temperature is 200°C, and the chain speed is 39 rpm;

[0035] (3) The hub is ground flat, and the place with high powder spraying is ground off;

[0036] (4) Spray painting: firstly carry out secondary pretreatment, including degreasing-surface conditioning-water washing-drying, then spray color paint with a thickness of 60um and a curing temperature of 195℃; and then spray clear paint with a thickness of 25um and a curing temperature of 195℃, the chain speed is 39 rpm;

[0037] (5) Tool processing: Use the wheel hub auxiliary processing tool to p...

Embodiment 3

[0041] A coloring process for wheel hubs comprises the following steps in turn:

[0042] (1) Surface treatment: pre-treatment is performed after rough grinding of the hub blank, including degreasing-water washing-surface conditioning-chromating-water washing-drying. In the drying step, the temperature is 140°C, and the chain speed is 30 rpm;

[0043] (2) Powder spray body: The thickness of the powder spray body is 150um, the curing temperature is 190°C, and the chain speed is 34 rpm;

[0044] (3) The hub is ground flat, and the place with high powder spraying is ground off;

[0045] (4) Spray painting: firstly carry out secondary pretreatment, including degreasing-surface conditioning-water washing-drying, then spray color paint with a thickness of 50um and a curing temperature of 185℃; and then spray clear paint with a thickness of 20um and a curing temperature of 185°C, the chain speed is 34 rpm;

[0046] (5) Tool processing: Use the wheel hub auxiliary processing tool to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com