Square cabin, manufacturing method of square cabin and generator set using square cabin

A manufacturing method and shelter technology, applied in the direction of engine components, machines/engines, supporting machines, etc., can solve problems such as loud noise, noise pollution, and reduced working efficiency of generator sets, and achieve the effect of reducing weight and noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

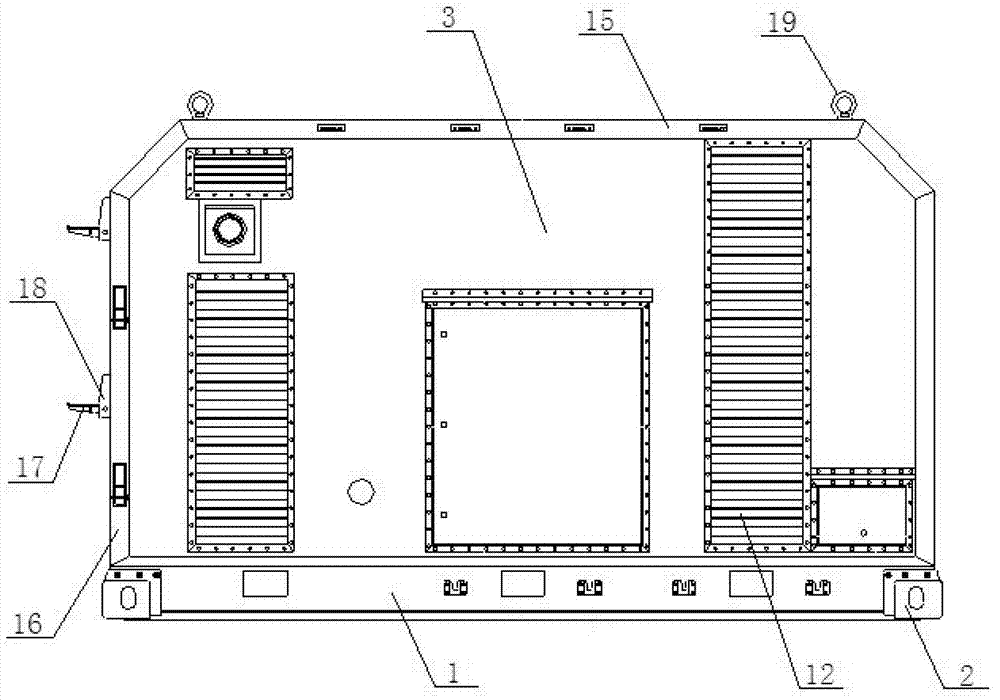

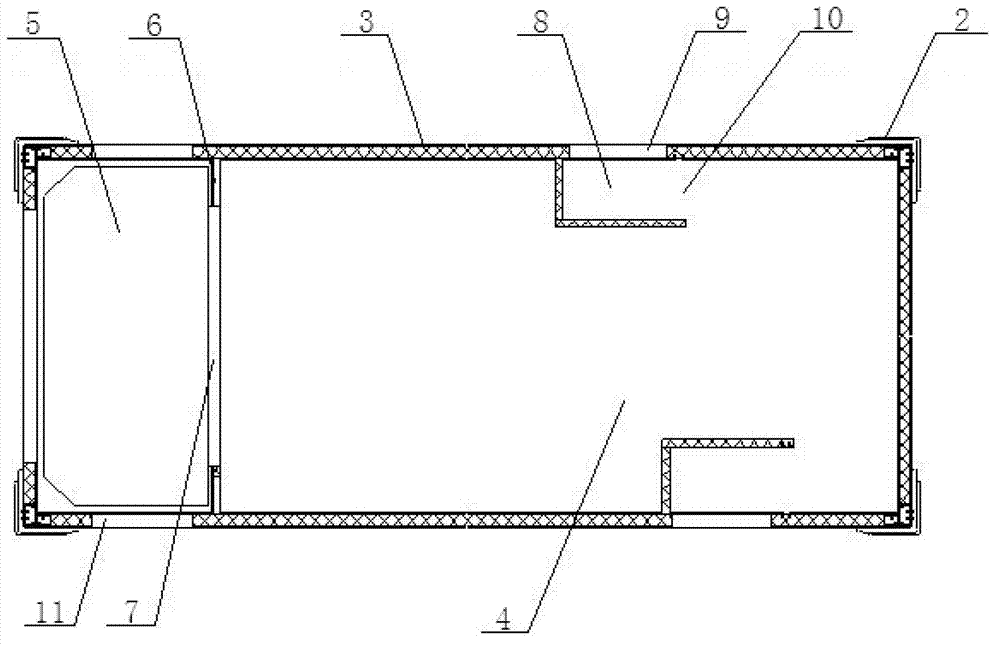

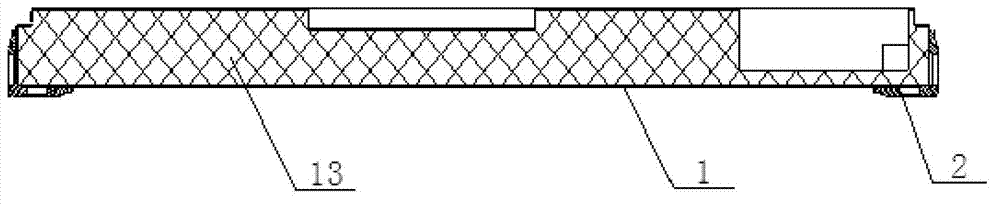

[0069] like Figures 1 to 4 As shown, the shelter includes a base 1 and a frame; the frame is arranged on the base 1; a top plate and a plurality of side plates 3 are embedded in the frame; the shelter is jointly surrounded by the base 1, the top plate, side plates 3 and the frame; the shelter Divided into the equipment compartment 4 and the air outlet compartment 5, the equipment compartment 4 and the air outlet compartment 5 are separated by a partition 6; the partition 6 is provided with an air guide port 7; the inner side of the side plate 3 is provided with a porous metal plate; The inner side of the side plate of the equipment compartment 4 is connected with a detour air duct 8; the air inlet 9 of the detour air duct 8 is located on the side panel 3 connected thereto; and at least one turn is included between the air inlet 9 and the air outlet 10 of the detour air duct 8 The side plate 3 that constitutes the air outlet chamber 5 is provided with an air outlet 11; the air...

specific Embodiment 2

[0074] like Figure 5 Shown, the manufacture method of shelter, comprises the following steps:

[0075] 201) Make frame;

[0076] 202) The step of bonding the side plate and the porous metal plate together by pressing is specifically: laying the surface metal plate, the glass fiber cotton plate and the porous metal plate together sequentially, and pressing them into shape;

[0077] 203) Embedding the top plate and the side plate attached to the porous metal plate in the frame, and setting a circuitous air duct, a partition, and an air exhaust port;

[0078] 204) Making a base with a cavity inside;

[0079] 205) filling the cavity with a foaming agent;

[0080] 206) Foaming the blowing agent to form a foam that fills the entire cavity;

[0081] 207) Connect the frame and the base as a whole.

[0082] Wherein, steps 201 to 203 and steps 204 to 206 can be performed simultaneously, or steps 204 to 206 can be performed first, and then steps 201 to 203 can be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com