Self-cooling type multi-stage evaporation and refrigeration system and refrigeration method thereof

A self-cooling, stage evaporation technology, applied in the fields of air conditioning, energy saving and environmental protection, can solve the problem of lowering the temperature of the supply air, achieve the effect of improving the efficiency of evaporative cooling and avoiding a large number of humidification problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

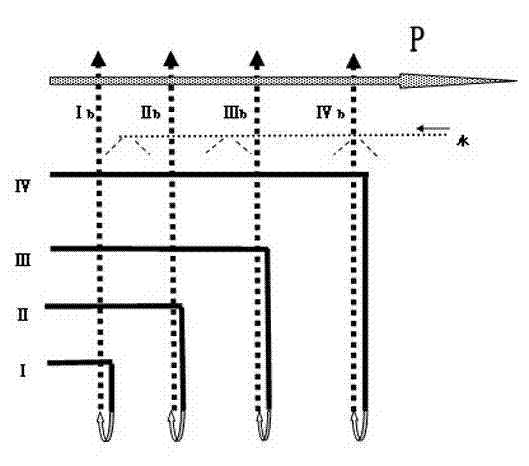

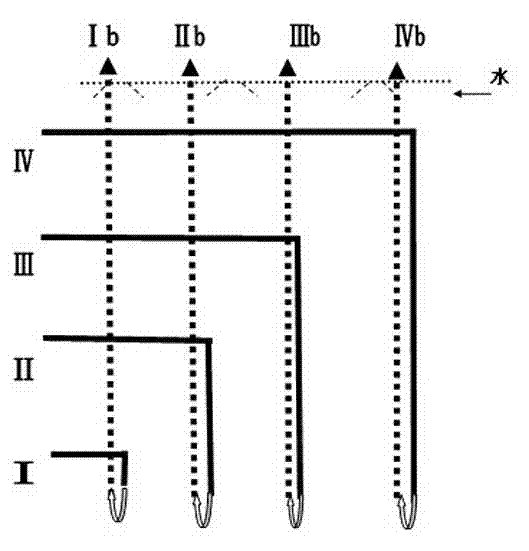

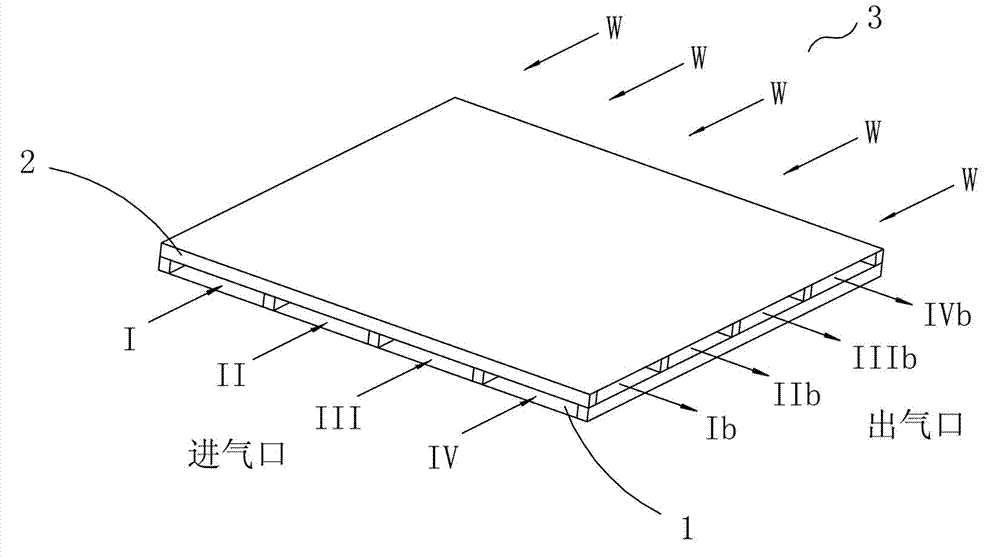

[0030] see Figure 1 to Figure 4 , is the system principle and structural diagram of the self-cooling multi-stage evaporative refrigeration described in the present invention, including a multi-stage indirect evaporator 1, a multi-stage direct evaporator 2 and a refrigerant evaporation heat-absorbing device 3, the multi-stage indirect evaporator 1 is composed of more than two stages of indirect evaporation dry channels 11, the multi-stage direct evaporator 1 is composed of wet channels 21 corresponding to the number of indirect evaporation dry channels 11, and the dry channels 11 and wet channels 21 are connected by joints The flow holes 12 are connected, and the multi-stage indirect evaporation dry passages 11 are arranged in sequence, and the dry passages of the next stage are adjacent to and crossed with the flow direction of all the wet passages of the previous stages.

[0031] Described dry channel 11 and wet channel 21 are made up of multi-layer partition wall 13 and gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com