Electrode active material, preparation method thereof, and electrode and lithium battery containing the same

An electrode active material, electrode technology, applied in the direction of lithium batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve problems such as battery performance deterioration, and achieve the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

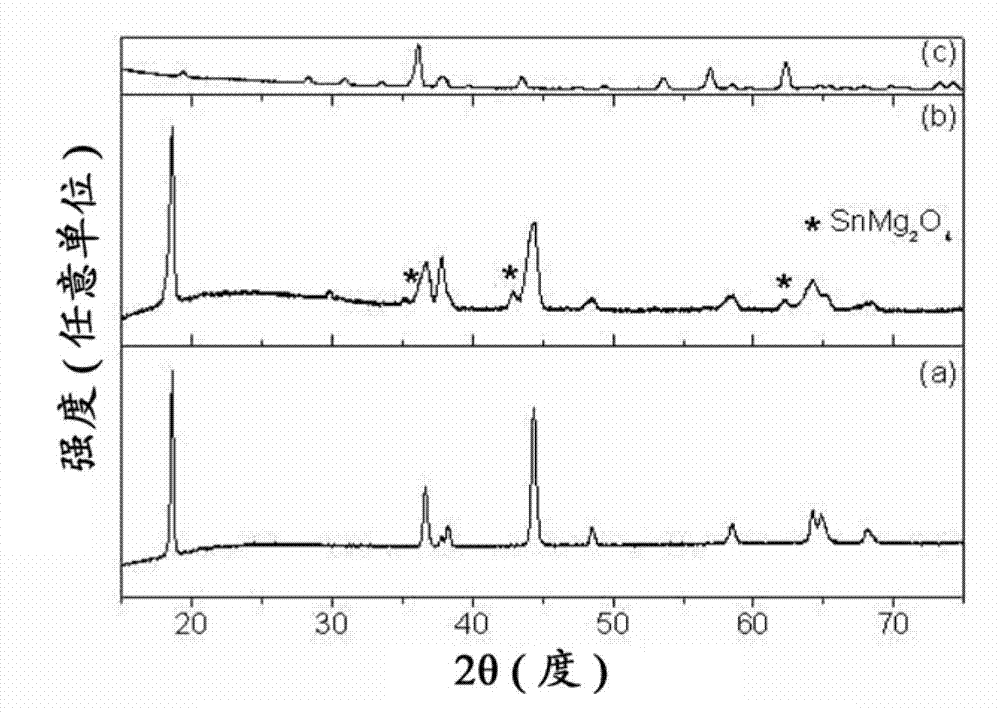

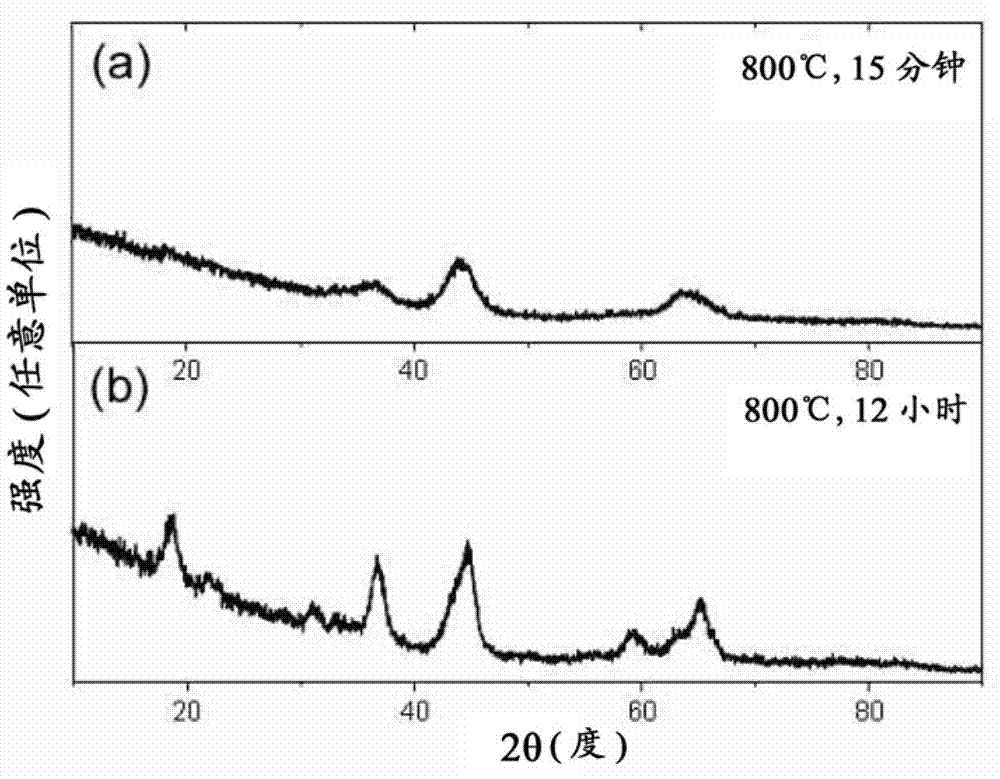

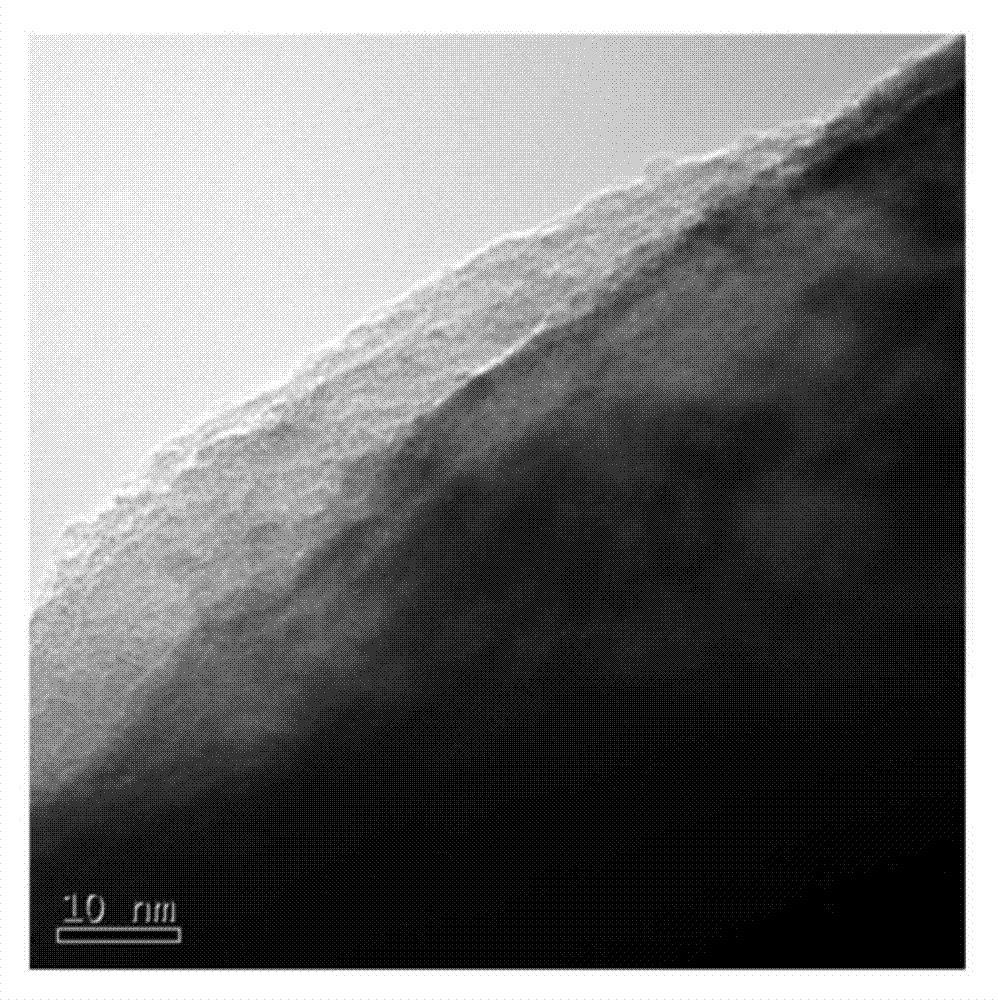

[0123] The stannous chloride (SnCl 2 ) and magnesium nitrate (Mg(NO 3 ) 2 ) were mixed at a molar ratio of about 1:2, and then water was added to the mixture to make a lithium-free oxide precursor slurry. Li with an average particle size of about 15 μm 1.1 Ni 0.35 mn 0.41 co 0.14 o 2 Added to and mixed with the lithium-free oxide precursor slurry. The mixture is baked at a temperature of about 850° C. in an oxygen atmosphere for about 12 hours to produce a compound including SnMg formed on its surface. 2 o 4 Li of the surface treatment layer 1.1 Ni 0.35 mn 0.41 co 0.14 o 2 core positive electrode active material.

[0124] The content of the precursor of the lithium-free oxide used is about 3% by weight, based on the precursor of the lithium-free oxide and Li 1.1 Ni 0.35 mn 0.41 co 0.14 o 2 of the total weight.

Embodiment 2

[0126] The positive electrode active material was fabricated using the same method as in Example 1, except that SnCl was used 2 and zinc acetate (Zn(O 2 CCH 3 ) 2 ) as a precursor to lithium-free oxides to form including SnZn 2 o 4 surface treatment layer.

Embodiment 3

[0128] The positive electrode active material was fabricated using the same method as in Example 1, except that Mg(NO 3 ) 2 and aluminum nitrate (Al(NO 3 ) 3 ) as a precursor to lithium-free oxides to form 2 o 4 surface treatment layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com