Manufacturing method for glass film and manufacturing device therefor

A technology of glass film and manufacturing method, applied in glass manufacturing equipment, glass cutting device, glass forming and other directions, can solve the problems of glass film belt breakage, breakage, futileness, etc., and achieve the effect of no bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

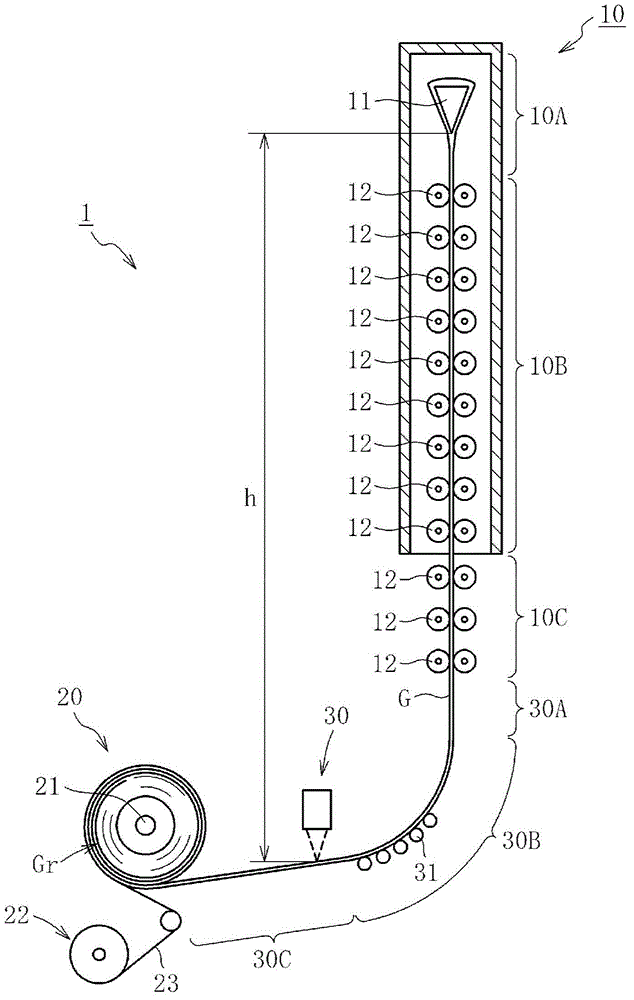

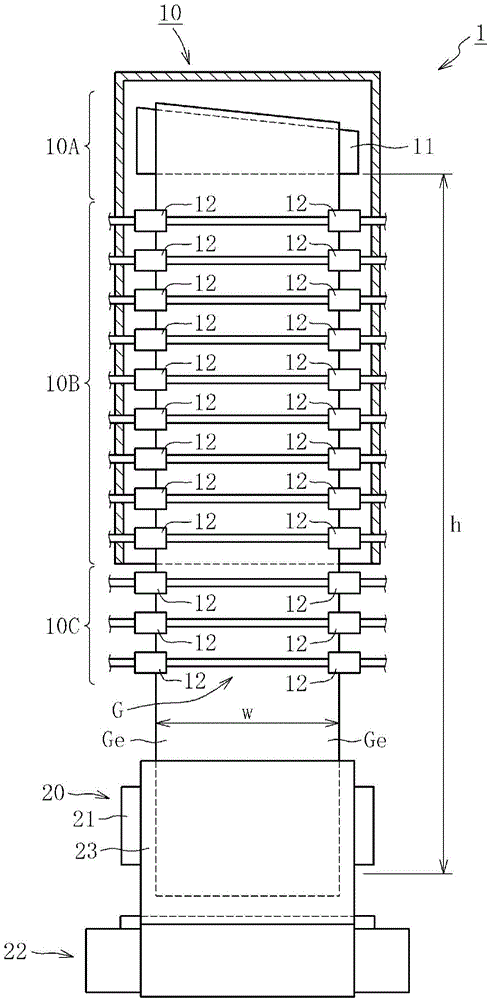

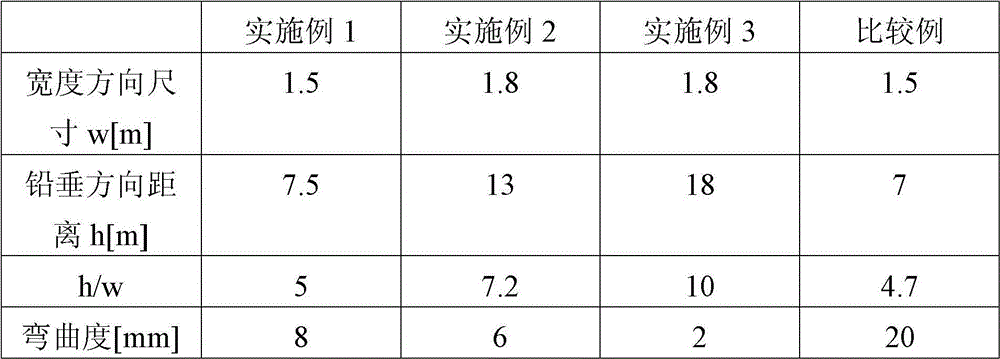

[0032] Below, based on figure 1 and figure 2 An embodiment of the present invention will be described.

[0033] figure 1 It is a side view of the glass film manufacturing apparatus 1 according to an embodiment of the present invention. As shown in the figure, the manufacturing apparatus 1 includes a forming apparatus 10 that forms a glass film ribbon G from molten glass by the so-called overflow down-draw method, and winds the glass film ribbon G drawn downward as it cools. The roll-shaped winding device 20 cuts the glass film ribbon G drawn downward in the width direction through the width direction cutting device 30 arranged on the upstream side of the winding device 20, thereby obtaining a predetermined The glass film roll body Gr of the roll thickness.

[0034] In detail, a molded body 11 having a wedge-shaped cross-sectional outer surface shape is arranged inside the molding device 10, and glass (melted glass) melted in a furnace (not shown) is supplied to the molded body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com