Slider structure

A sliding block and inclined plane technology is applied in the field of sliding block structure of stamping and bending dies, which can solve the problems of increasing mold manufacturing cost, complicated chute processing, and high mold manufacturing cost, and achieves improved mold repairing efficiency, simple structure, and reduced manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

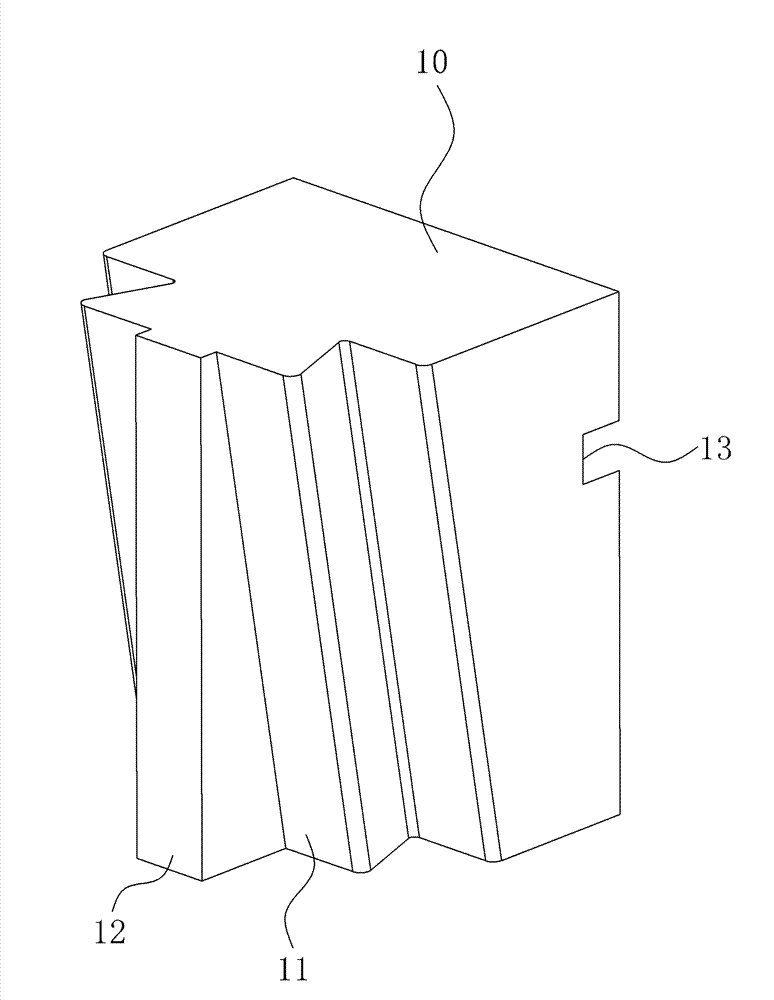

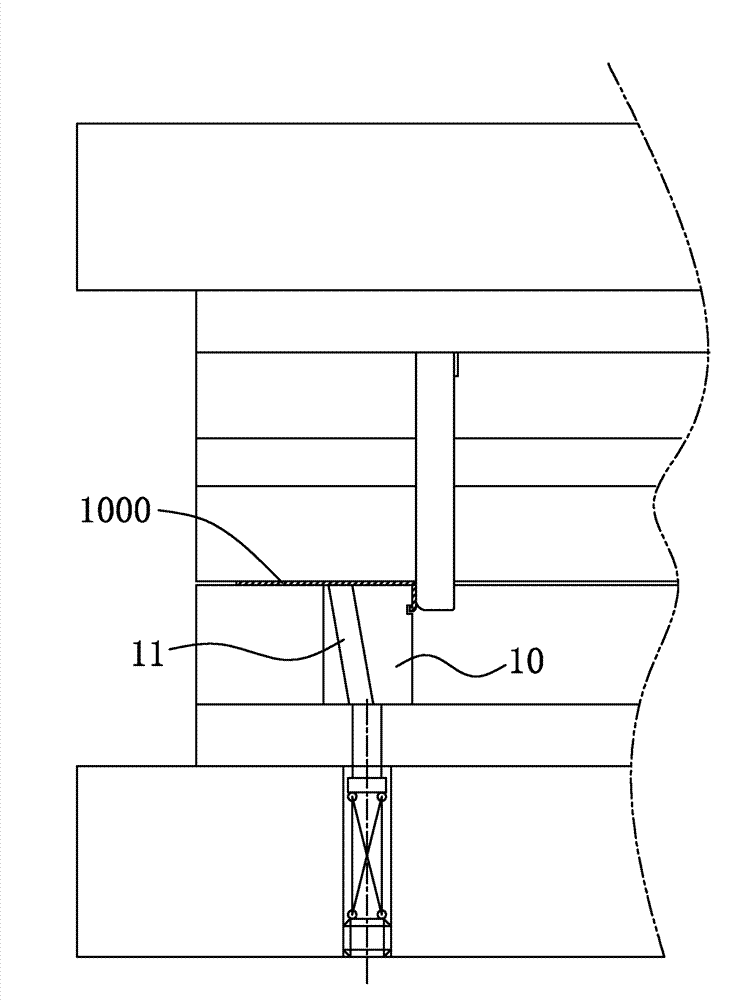

[0024] Please refer to Figure 3 to Figure 7 , a preferred embodiment of the slider structure of the present invention is applied to a stamping die to form a product 1000 with inner hooks and bends. The plate 400, the lower template 500, the lower backing plate 600, the punch 700 and the ejector pin 800 are characterized in that the slider structure of the present invention includes the slider body 20, the first input block 30 and the second input block 40.

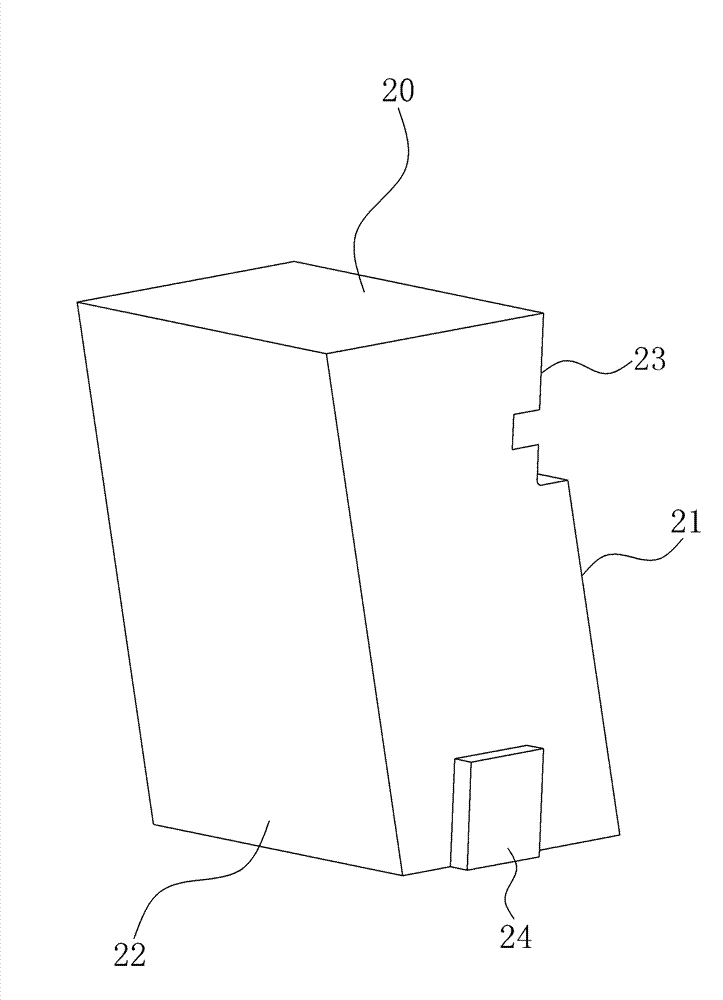

[0025] The slider body 20 has a first inclined surface 21 and a second inclined surface 22 parallel to each other, wherein the first inclined surface 21 participating in forming is provided with a bending forming structure 23 . Preferably, in this embodiment, the two sides of the slider body 20 are respectively provided with a lifting lug 24, which is used to limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com