Manual inner wall holding device and method of thin wall cylindrical component

A clamping device and a thin-walled cylinder technology, which is applied to the field of manual clamping devices for the inner wall of thin-walled cylindrical parts, can solve problems such as easily damaged parts and cannot meet the requirements of precision assembly, and achieve the effect of ensuring non-destructive clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

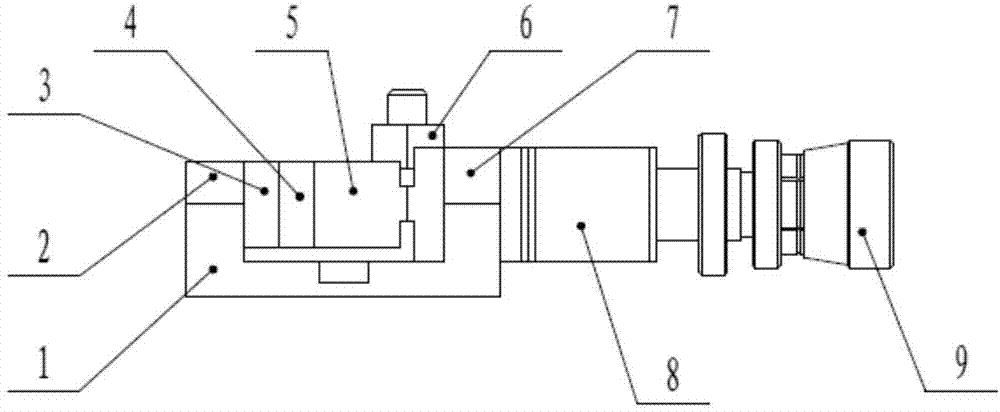

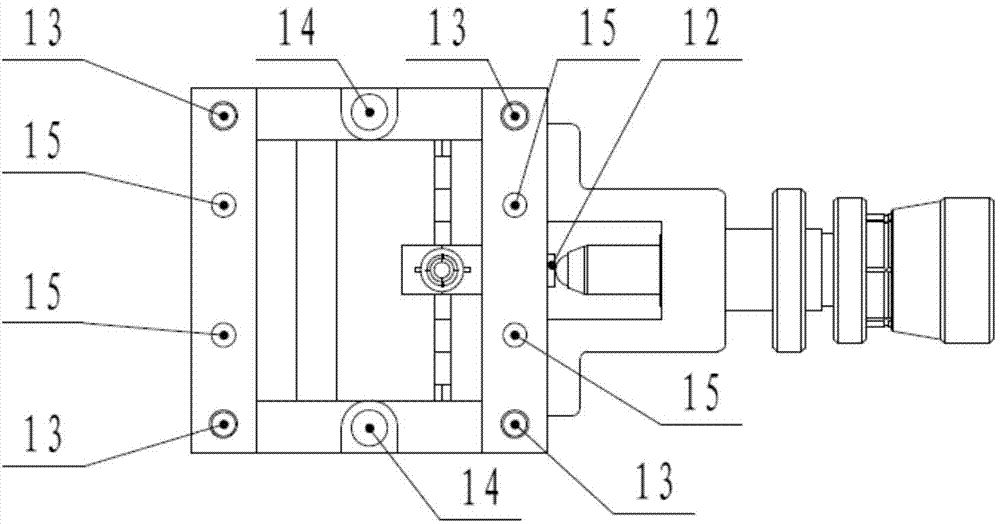

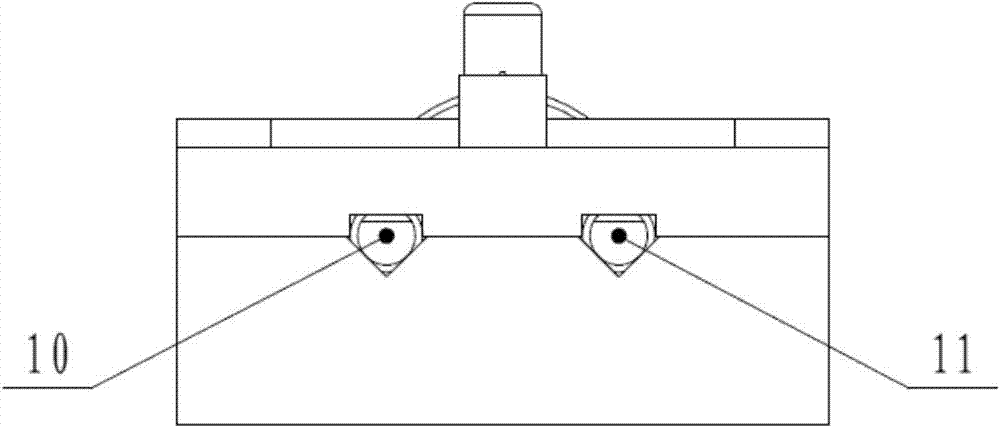

[0026] figure 1 It is the front view of the clamping device for the inner wall of the thin-walled cylindrical part of the present invention, figure 2 It is a top view of the clamping device for the inner wall of the thin-walled cylindrical part of the present invention, as figure 1 , 2 As shown, the clamping device of the present invention mainly includes: a base 1, a left fixed seat 2, a silica gel pad 3, a micro force sensor 4, a moving clamping end 5, a fixed clamping end 6, a right fixing base 7, and a differential micrometer head Fixing seat 8, differential micrometer head 9, support shaft A10, support shaft B11, top column 12, screws 13, 14, top screw 15, shaft sleeve A16, shaft sleeve B18, shaft sleeve C22, shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com