Automatic film laminating machine

A laminating machine, automatic technology, applied in the direction of lamination device, control lamination, lamination, etc., can solve the problems of low yield, poor lamination accuracy, low efficiency, etc., to achieve product accuracy and high lamination speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

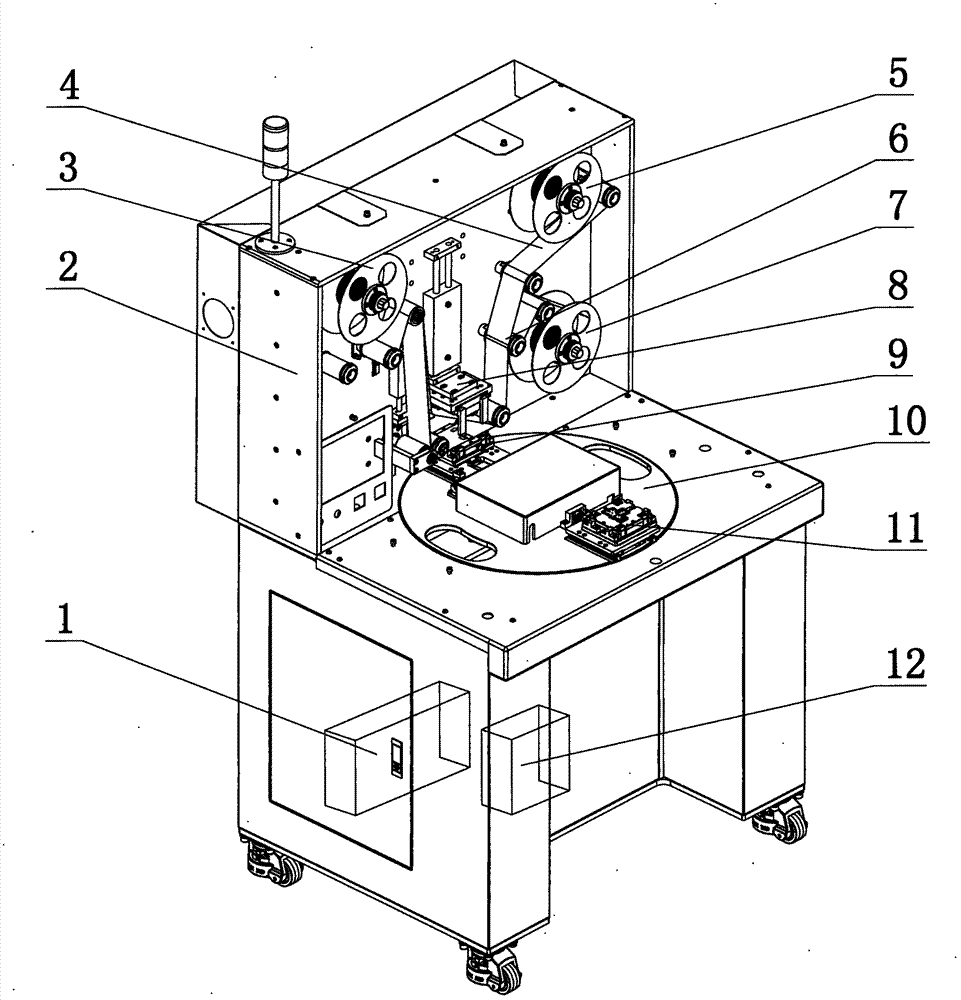

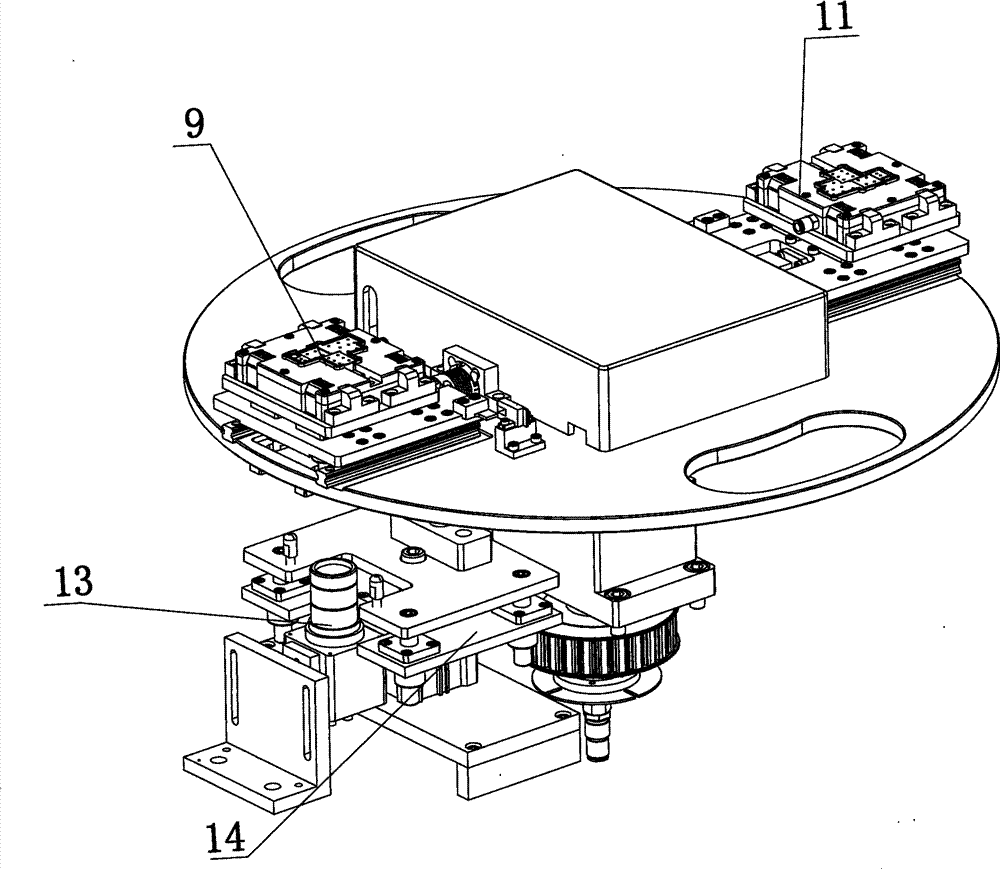

[0019] Such as figure 1 , figure 2 A kind of film automatic laminating machine shown, comprises laminating machine support, is provided with workbench on the laminating machine support, and this workbench side is distributed with machine table shell 2, and its difference is: the present invention The adopted workbench is embedded with a turntable 10, and the first workpiece station 9 and the second workpiece station 11 are correspondingly distributed on the turntable 10, and observation holes are distributed on the turntable 10 at the same time. Looking further, the present invention is provided with an independent upper positioning assembly 14 under the first workpiece station 9 and the second workpiece station 11 . At the same time, an image positioning device is provided on the top positioning assembly 14 . Considering the smooth fitting of parts, a pressure head assembly 8 is arranged above the working end of the turntable 10 . Specifically, a separating roller 6 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com