Touch screen laminating method and glue coating device thereof

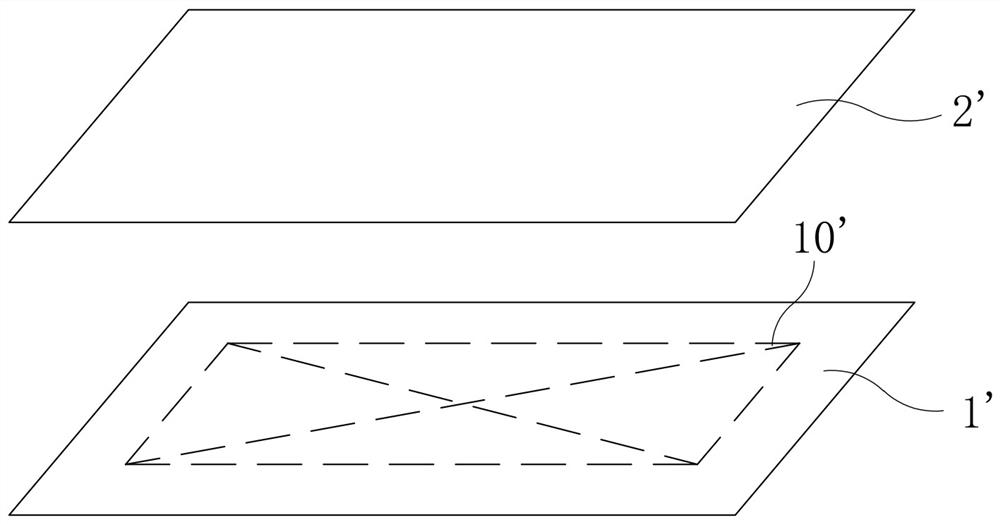

A coating device, touch screen technology, applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, can solve the problems of uneven thickness of glue 10', incomplete removal of bubbles, uneven thickness of glue, etc., Achieve the effect of fast lamination, complete removal of air bubbles, and poor fluidity of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

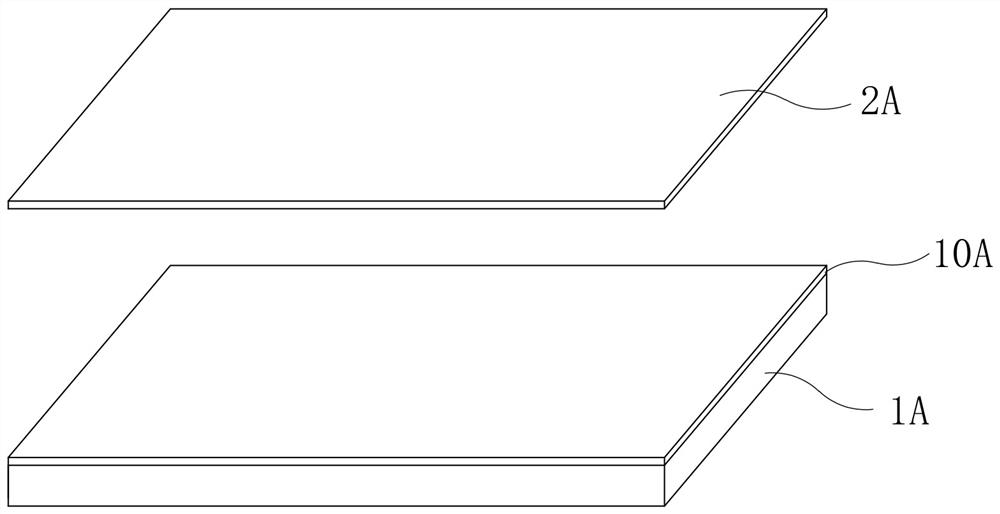

[0027] Such as figure 2 As shown, the present invention is a touch screen bonding method, comprising the following steps:

[0028] 1. Use a coating knife to coat the glue 10A on the entire surface of the cover plate 1A. The glue 10A is in a planar shape. The glue 10A used in this embodiment is: two-component UV glue; the two-component UV glue Composed of UV glue and curing agent, the ratio of UV glue and curing agent is 10:1; UV glue and curing agent are mixed and coated on the entire surface of the cover plate 1A by a coating knife.

[0029] 2. Use a UV lamp to irradiate the cover plate 1A coated with glue 10A to activate the glue. After it solidifies, it becomes jelly-like and not easy to flow. The irradiation time is 1-20 seconds, and the irradiation power of the UV lamp is 0.5-5 watts;

[0030] 3. In a vacuum environment, attach the display screen 2A to the cover plate 1A to avoid air bubbles.

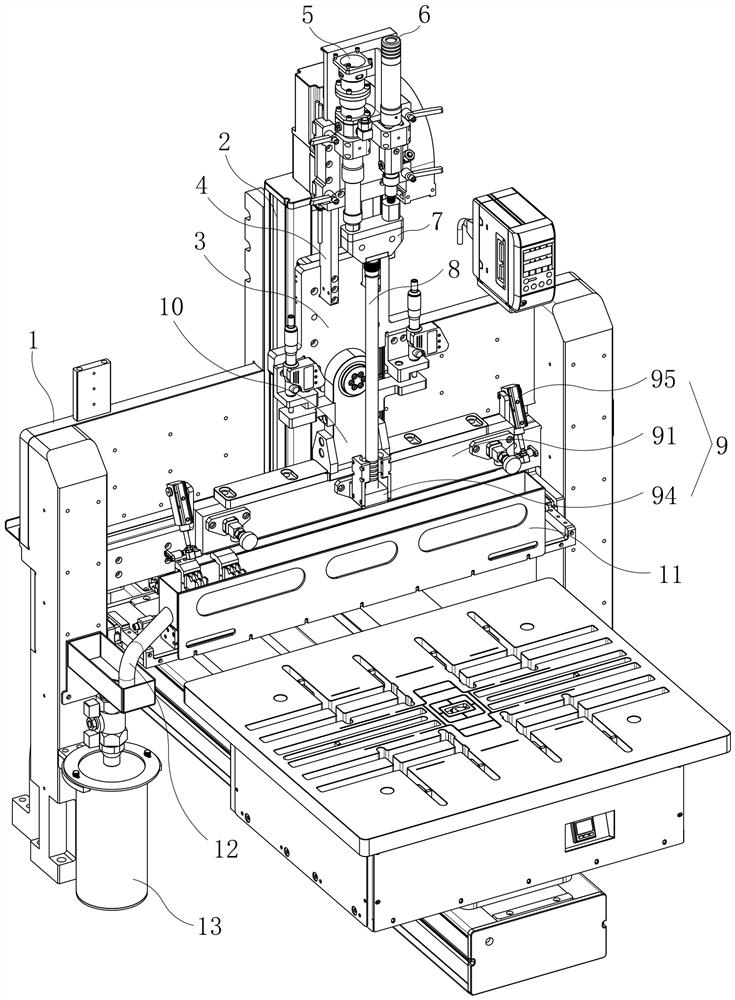

[0031] Such as image 3 As shown, the present invention is a glue coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com