Performance test bench for reaction torque device of helicopter

An anti-torque and helicopter technology, applied in the field of test benches, can solve the problems of inability to simulate test research, affect the development or pre-research progress of helicopter models, and have no special test platform, and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

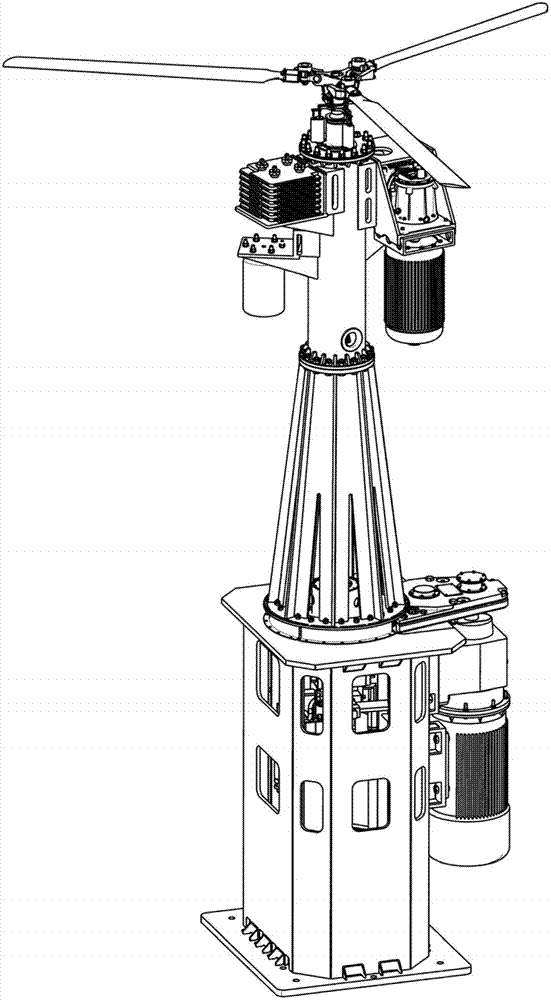

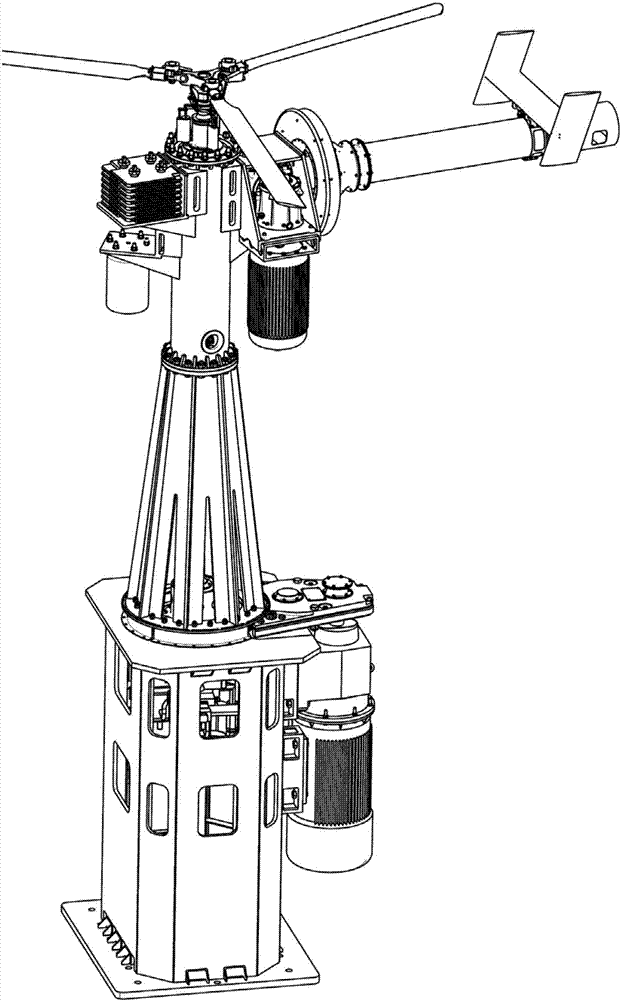

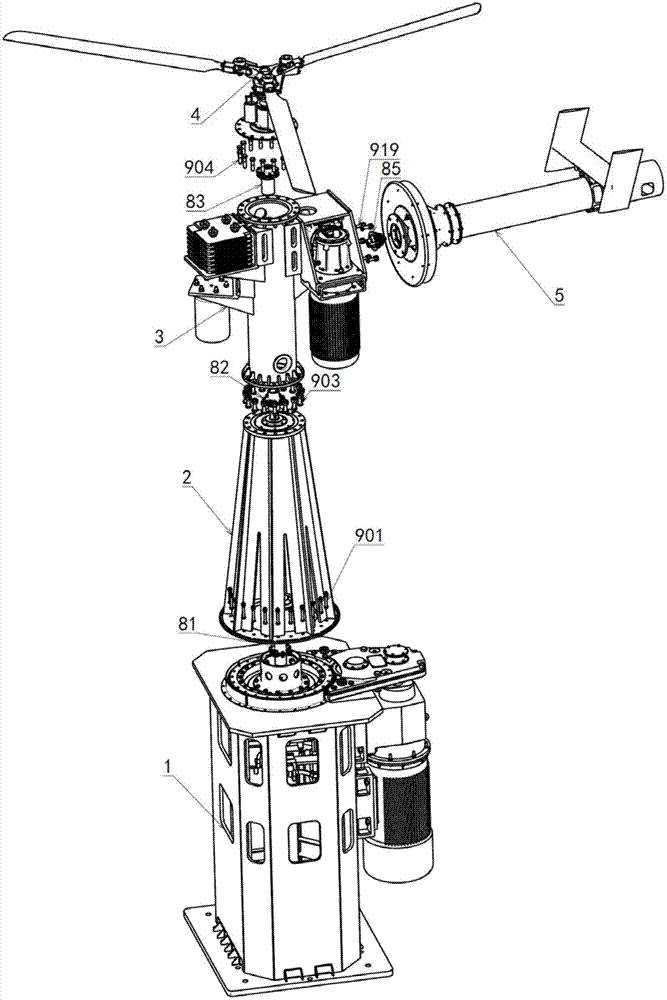

[0038] exist figure 1 In , the configuration of the entire anti-torque device test rig is shown, excluding the anti-torque device test piece. From bottom to top are the lower platform assembly 1, the middle platform assembly 2, the upper platform assembly 3 and the rotor system 4. figure 2 A schematic diagram of the simulation test of the entire anti-torque device test bench is shown, and the test piece 5 in the figure is a non-tail rotor anti-torque system.

[0039] image 3A component-level exploded view of the test rig containing the test piece is shown. Between the lower platform assembly 1 and the middle platform assembly 2, between the middle platform assembly 2 and the upper plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com