Paper feeding method of slot machine

A paper feeding and paper machine technology, applied in the field of servo paper feeding slot machines, can solve problems such as poor product pressure resistance, affecting product quality, equipment obstacles, etc., to improve product quality, ensure product quality, and reduce failure rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

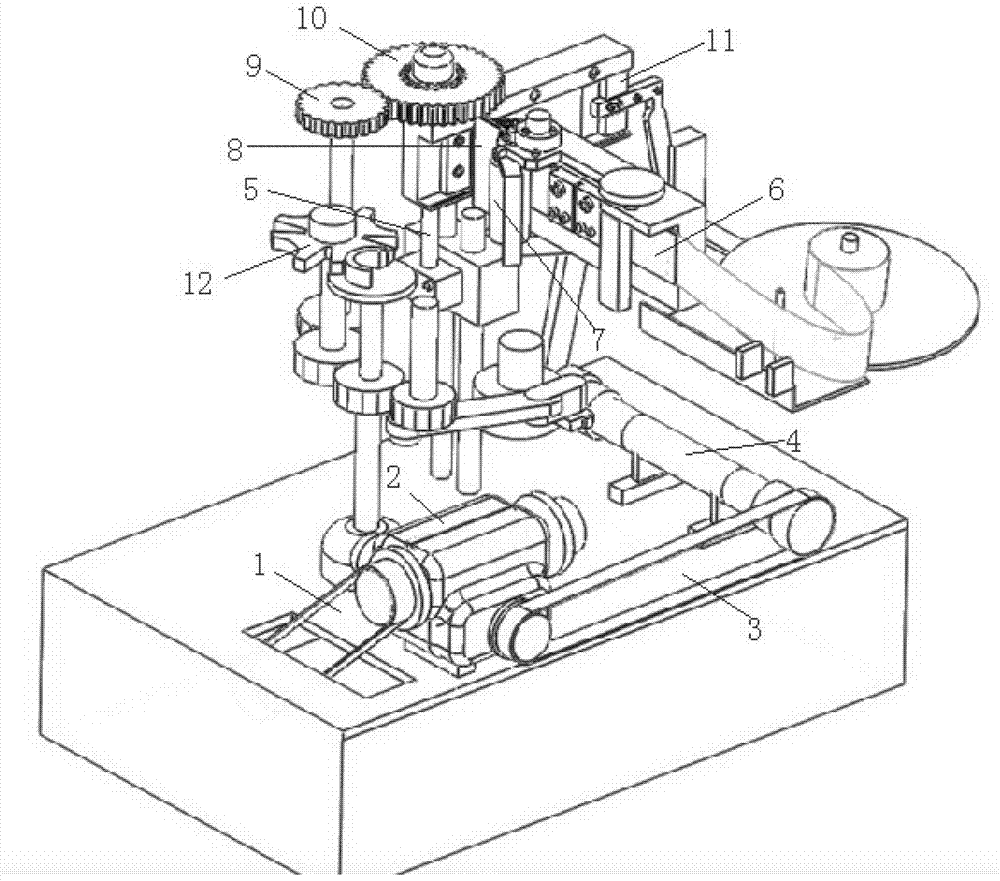

[0012] In order to better understand the present invention, the working principle of the existing servo paper feeding slot paper machine will be described below.

[0013] Referring to the accompanying drawings, a kind of servo paper feed slot paper machine, its motor power is transmitted to the reducer 2 through the belt 1, and the reducer 2 passes a part of the power through the synchronous belt 3 and the transmission shaft 4 to control the cutter 11 to cut the slot paper and The ejector rod 5 pushes the cut paper pieces into the stator core; the other part of the power of the speed reducer passes through the indexer 12, the gears 9, 10 to control the number of grooves of the paper in the stator core. The stator core is designed with large and small slots. When the large slot is feeding paper and the small slot is not, the paper in the small slot will swing with the paper guide plate 8.

[0014] In combination with the above-mentioned grooved paper machine, a paper feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com