Blast oxygen enrichment mixing energy-saving device of blast furnace

A blast furnace blast and energy-saving device technology, applied to blast furnace details, blast furnaces, blast furnace parts, etc., can solve the problems of high investment and operating costs of oxygen compressor equipment, and achieve the effects of simple structure, convenient maintenance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

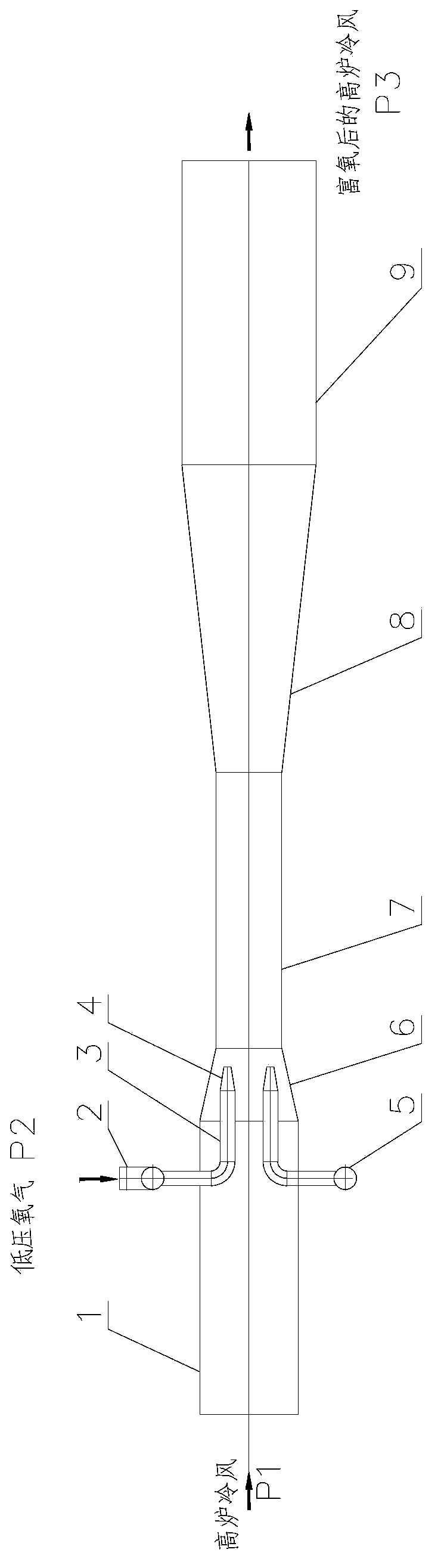

[0010] Such as figure 1 As shown, a blast furnace blast and oxygen-enriched mixing energy-saving device includes a cold air pipe 1, a receiving chamber 6, a mixing chamber 7, and an expansion chamber 8, which are sequentially connected from front to back. The distribution loop 5 passes through a branch pipe 3 with a nozzle 4 from The cold air duct 1 is inserted into the receiving chamber 6, the oxygen duct 2 is connected to the inlet of the distribution loop 5, and the cold air blown by the blast furnace blower enters from the rear of the cold air duct 1. The gas pressure P1 of the blast furnace blast is greater than the oxygen pressure P2. The blast furnace blast pressure P1 is greater than 0.15MPa, and the oxygen pressure is less than 0.1MPa. The blast furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com