Compensation process of high furnace iron-making air blast system

A technology of blast furnace ironmaking and compensation method, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as unbalanced furnace conditions, material collapse, and less active tuyere, to achieve stable furnace conditions, optimize technical and economic indicators, The effect of improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

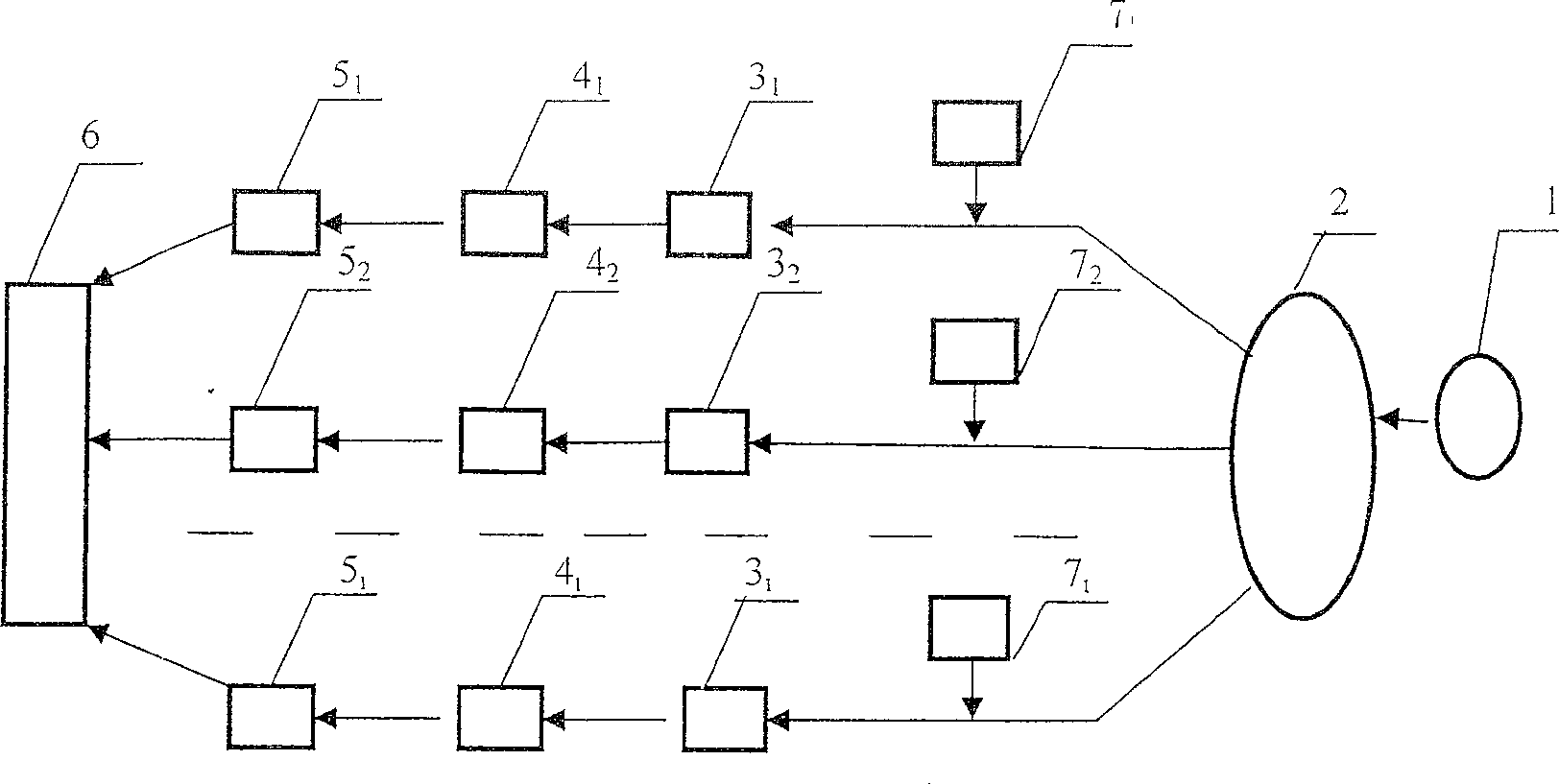

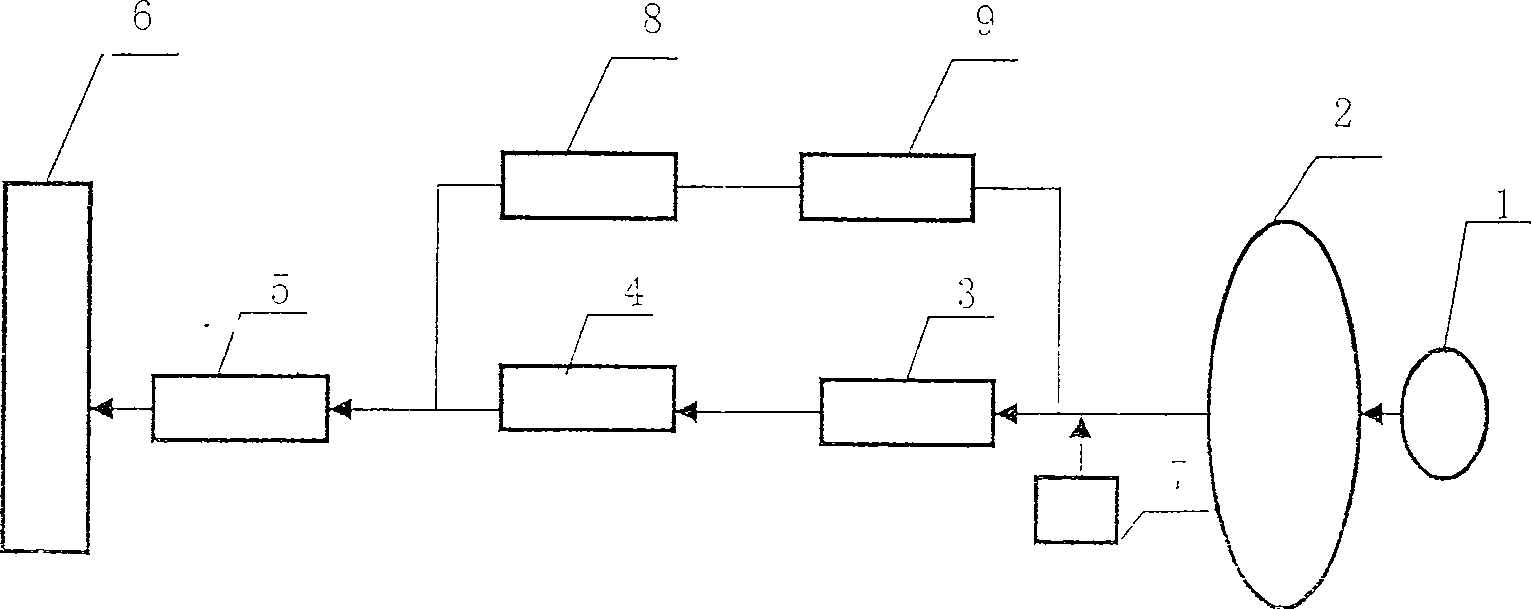

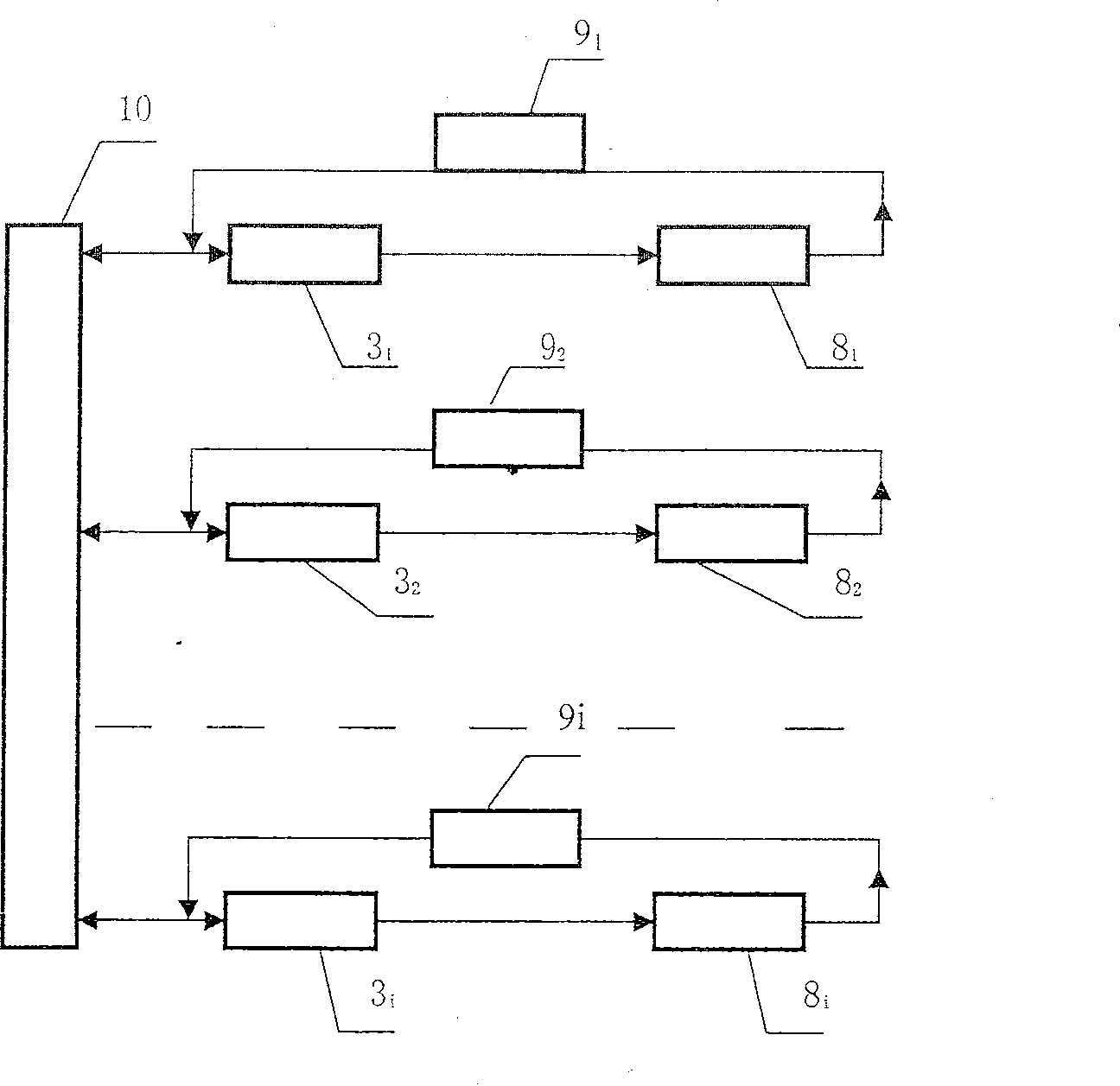

[0018] Depend on figure 1 , figure 2 , image 3 It can be seen that the compensation method for the blast furnace ironmaking air supply system includes a booster pump 1, a pressure equalizing tank 2, an electric valve 3, a blast kinetic energy detector 8, a single tuyere processor 9, and a central processing unit 10. Air at normal temperature is pressurized by booster pump 1, pressure equalized by pressure equalizing tank 2, and industrial pure oxygen 7 is added to form an oxygen-rich air flow. The electric valve 3 is connected to the gradient tube or the Laval tube 4 and the blast kinetic energy detector 8 in sequence, and is connected to the straight blowing tube 5 . The blast kinetic energy detector 8 adopts an elbow flowmeter, and the single tuyere processor 9 is electrically connected with the blast kinetic energy detector 8, the central processing unit 10 and the electric valve 3 respectively. The normal temperature air used for compensation is pressurized by the boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com