Method for determining blast furnace proper wind opening diameter

A tuyere and blast furnace technology, applied in the direction of the tuyere, etc., can solve the problem that the diameter of the tuyere does not match the smelting conditions or the diameter of the hearth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

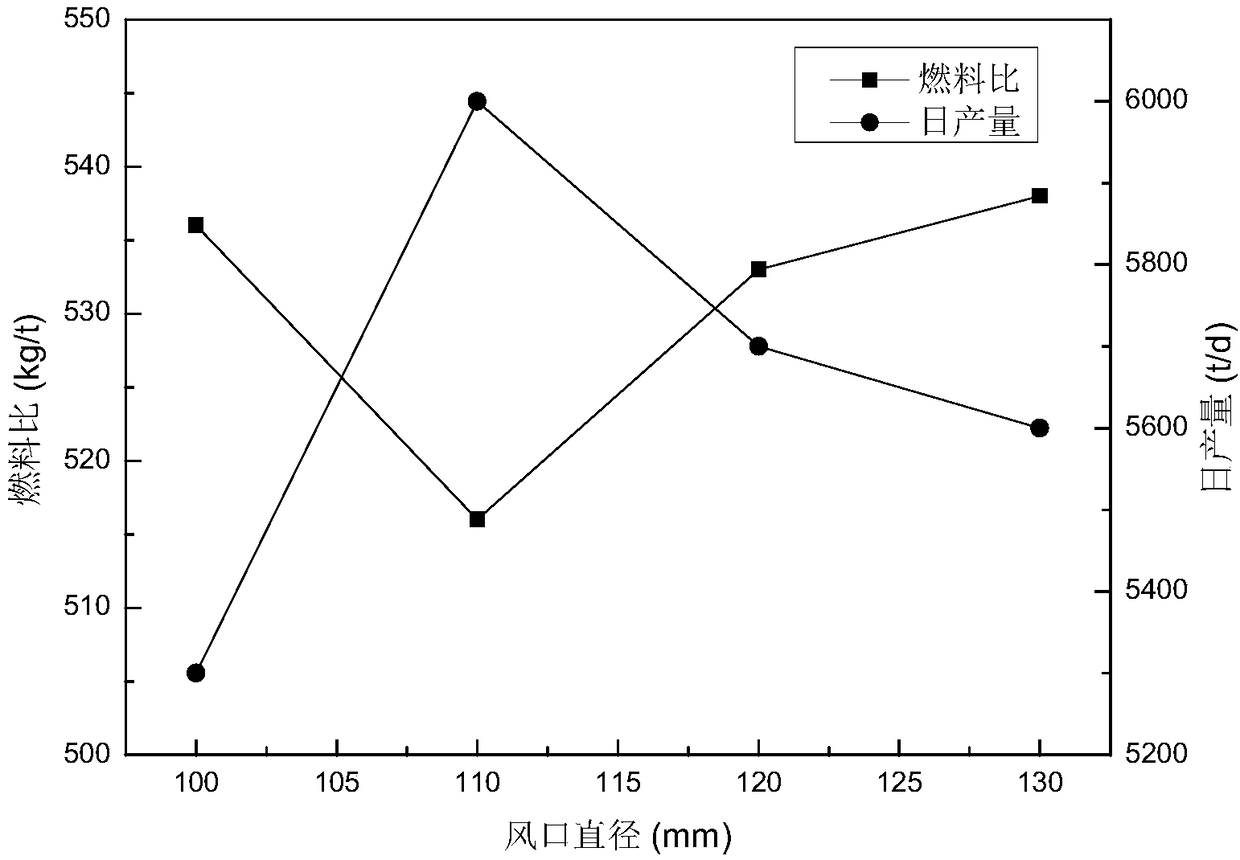

[0072] A certain 3200m 3 Blast furnace, hearth diameter D is 12.4m, equipped with 32 tuyeres, wind pressure p is 370kPa, air volume Q is 5500m 3 / min, wind temperature t w It is 1200°C.

[0073] The calculation steps are as follows:

[0074] 1. Firstly, according to steps 1 and 2, the suitable blast furnace tuyere convoluted depth is calculated by formula (2) to be 1.815m (M is taken as 0.5);

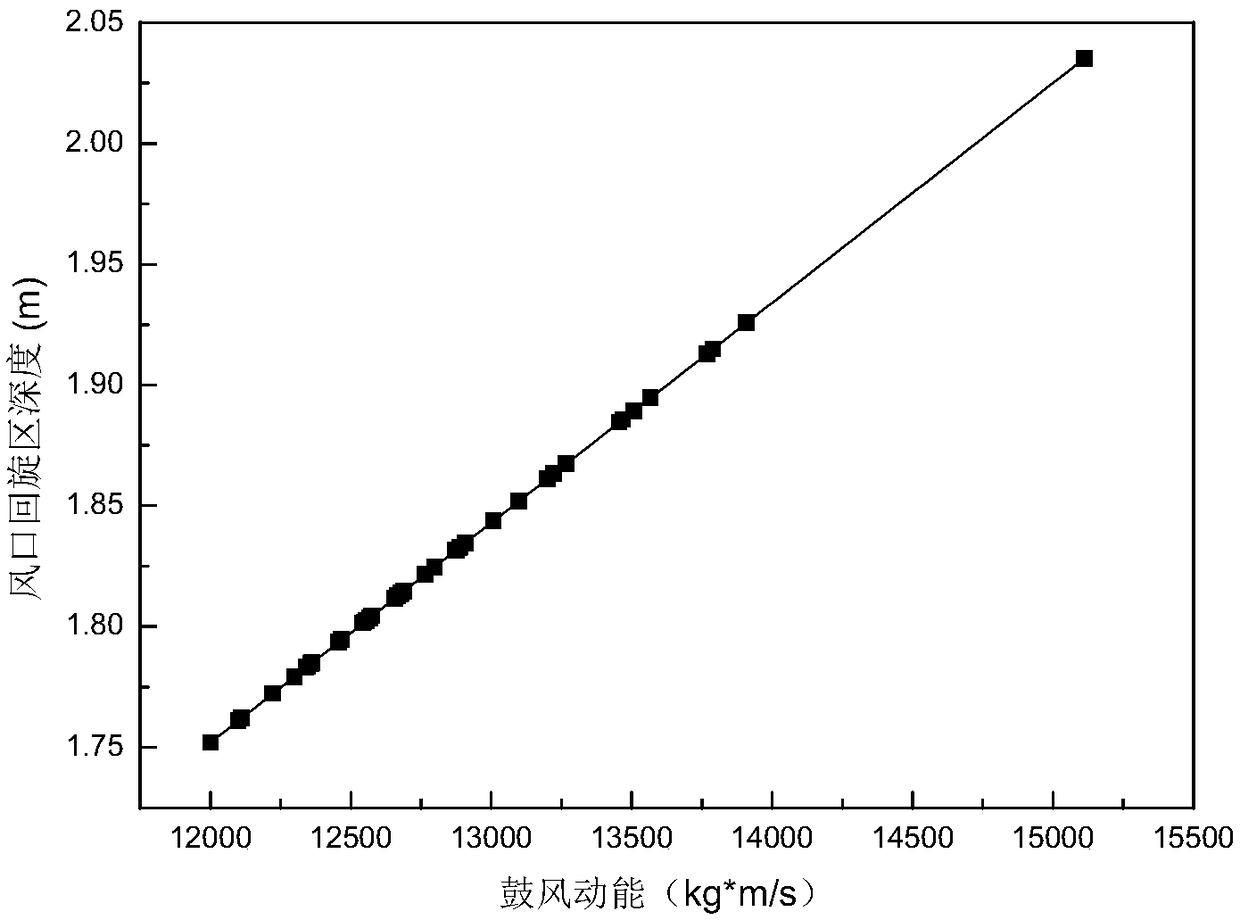

[0075] 2. According to step 3, count the mathematical relationship between L and E, see figure 1 ;

[0076] 3. According to step 4, through the figure 1 The formula (4) obtained by the regression analysis of the relationship graph is specifically:

[0077] L=0.86+0.91×10 -4 E-0.202

[0078] 4. According to steps 5 and 6, the suitable blast kinetic energy of blast furnace calculated by formula (4) is 1.245×10 4 kg m / s;

[0079] Calculated by the formula (5), the total area of the blast outlet is 0.43594m 2 ;

[0080] Calculated by formula (6), the diameter of a single tuyer...

specific Embodiment 2

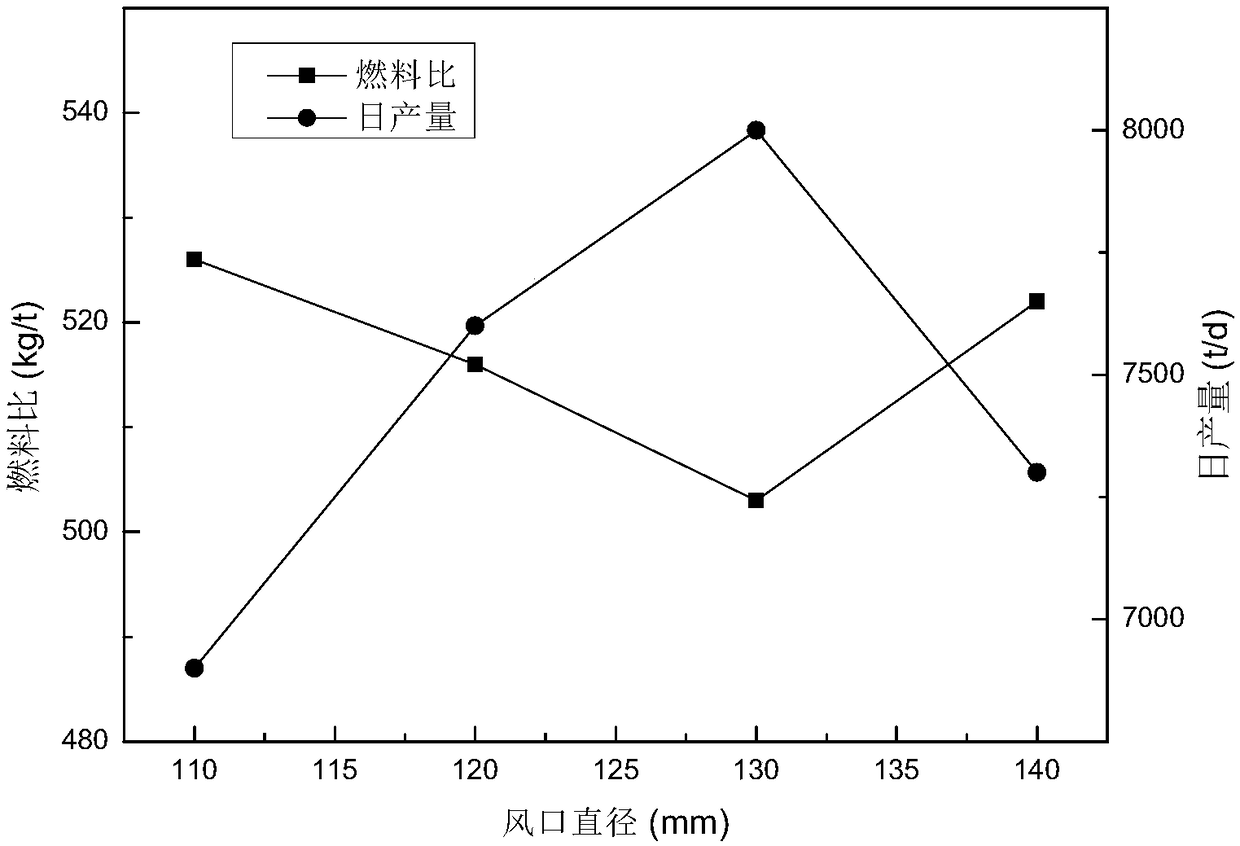

[0082] A 2580m3 blast furnace in China has a hearth diameter of 11.5m, equipped with 30 tuyeres, a coal ratio of 120kg / t, a wind pressure of 350kPa, and an air volume of 3900m 3 / min, wind temperature 1200°C.

[0083] The calculation steps are as follows:

[0084] 1. First, according to steps 1 and 2, the suitable blast furnace tuyere convoluted depth is calculated by formula (2) to be 1.684m (M is taken as 0.5);

[0085] 2. According to step 3, count the mathematical relationship between L and E, see figure 1 ;

[0086] 3. According to step 4, through the figure 1 The formula (4) obtained by the regression analysis of the relationship graph is specifically:

[0087] L=0.86+0.91×10 -4 E-0.202

[0088] 4. According to steps 5 and 6, the suitable blast kinetic energy of blast furnace calculated by formula (4) is 1.027×10 4 kg m / s;

[0089] Calculated by formula (5), the total area of the blast outlet is 0.304m 2;

[0090] Calculated by formula (6), the diameter of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com