Connecting joint of upright column and crossbeam of curtain wall

A technology for connecting nodes and columns, which is applied in the field of connecting nodes between columns and beams of curtain walls, can solve the problems affecting the stability of the connection between beams and columns, the fixed installation method cannot be flexibly adjusted, and the operating space is limited, so as to achieve convenient and simple assembly, The effect of stable force and large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

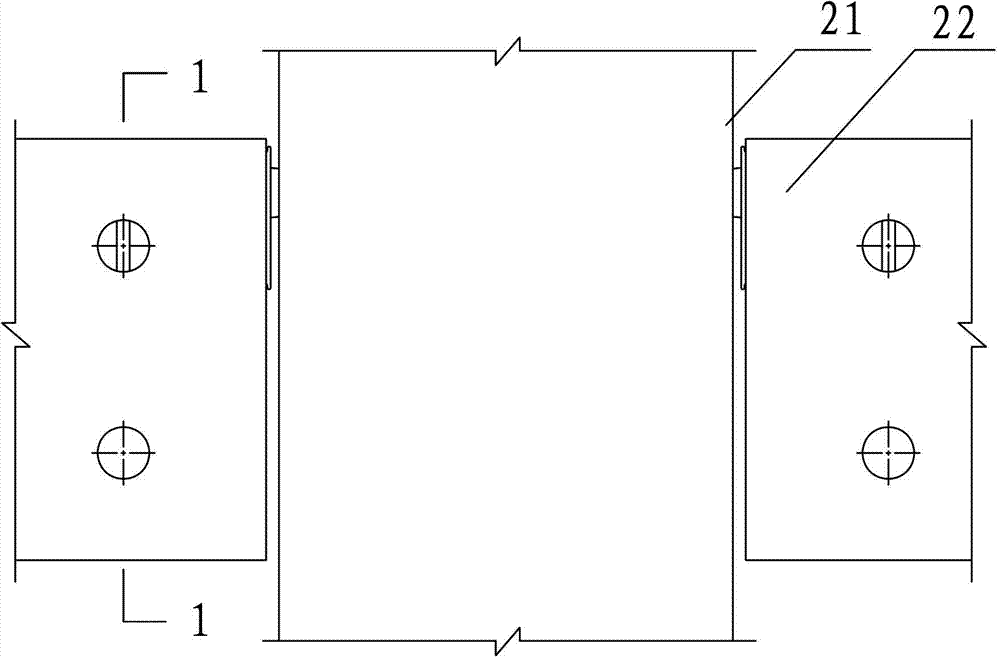

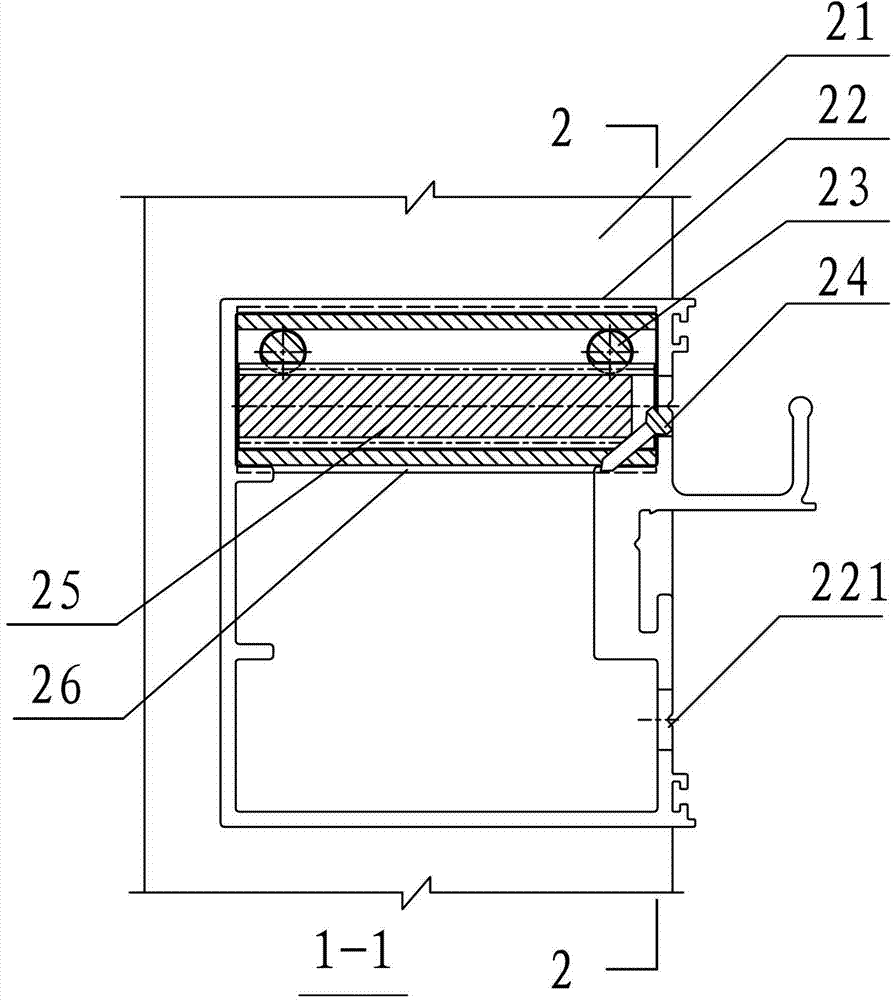

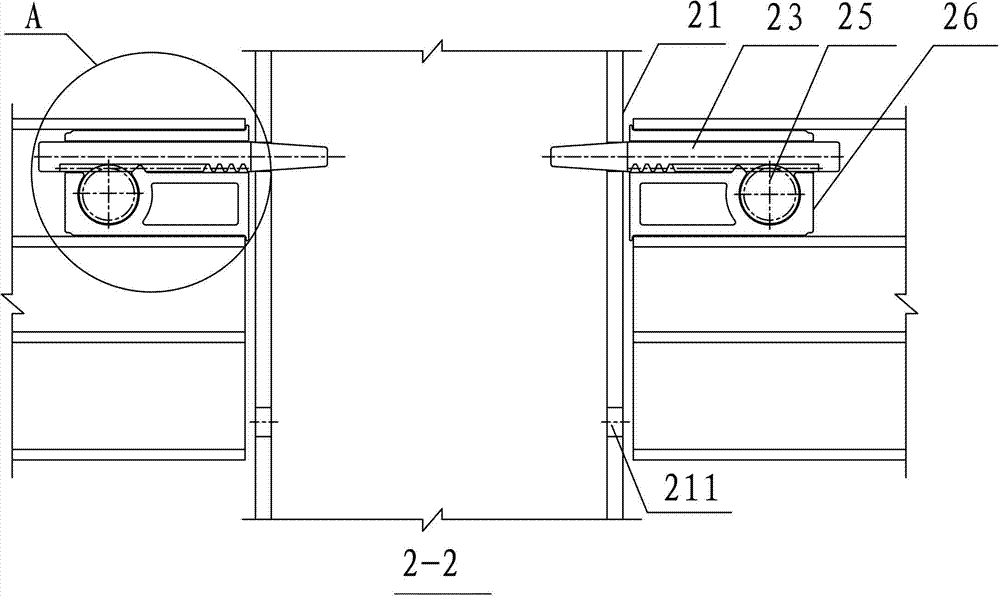

[0032] The present invention mainly connects the column 21 and the crossbeam 22, and mainly includes a toothed pin 23, a fastening screw 24, a spur gear 25, and a sleeve core 26.

[0033] The crossbeam 22 can be designed as a complete closed cavity to improve the compressive bending strength and torsional strength of the crossbeam 22 . In the cavity of the crossbeam 22, a space that can be inserted into the sleeve core 26 is designed, and the sleeve core 26 can be cut or customized according to the cross-sectional size of the crossbeam 22.

[0034] A circular cavity is provided inside the sleeve core 26 as a gear hole 262 for installing the spur gear 25 , and one end of the spur gear is provided with a slot 251 . On the gear hole 262 direction perpendicular to the sleeve core 26, drill two pin bolt holes 261 on the sleeve core accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com