Sound wave signal while drilling receiving device

The technology of an acoustic signal and a receiving device is applied in the field of wireless measurement while drilling, which can solve the problems of inability to measure high-frequency and weak acoustic signals, interference between acoustic signal measurement and reception, and influence on signal fidelity and reliability. Achieve the effect of improving sound wave receiving efficiency, improving receiving rate, improving flexibility and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

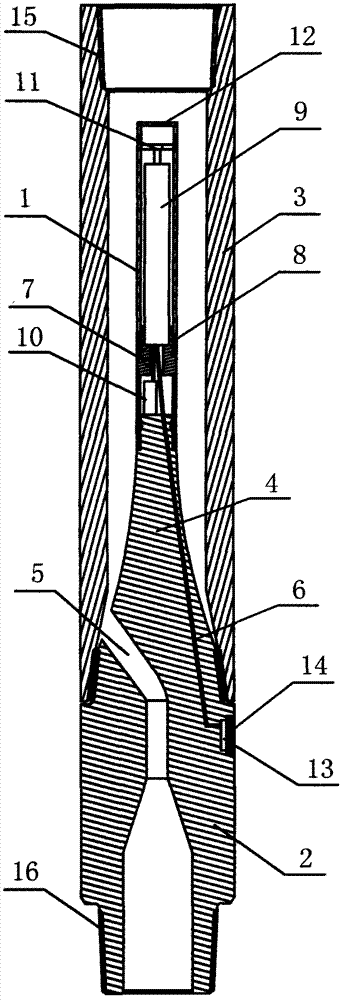

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] A while-drilling acoustic signal receiving device, the device includes an acoustic signal receiving equipment cylinder 1 and a lower joint 2, and an external protective sleeve 3 is sheathed on the exterior of the acoustic wave signal receiving equipment cylinder 1. The lower part of the lower joint 2 is set as a hollow structure, and the upper part is set as a horn structure 4. The sound wave signal receiving equipment cylinder 1 is connected to the upper end of the horn structure 4, and the outer protective sleeve 3 is connected to the lower end of the horn structure 4. Root connection. A slot 13 is slotted on the middle outer wall of the lower joint 2, and wireless communication equipment is placed in the slot 13, and a non-metallic cover 14 is provided on the slot 13. The lower part of the lower joint 2 is provided with an external thread 16, and the lower joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com