A construction device and method for super-long pipe curtain jacking without intermediate space

The technology of a construction device and construction method is applied in shaft equipment, earthwork drilling, wellbore lining, etc., and can solve problems such as increased construction cost, large deviation of jacking precision, and large soil settlement, and achieves convenient operation and control, and eliminates Unfavorable factors, the effect of high construction precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

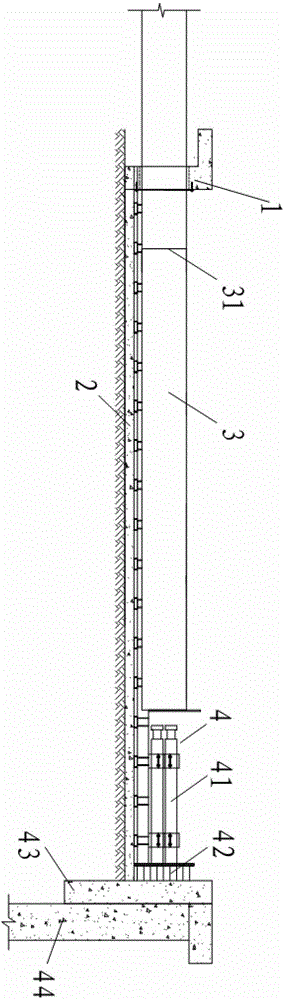

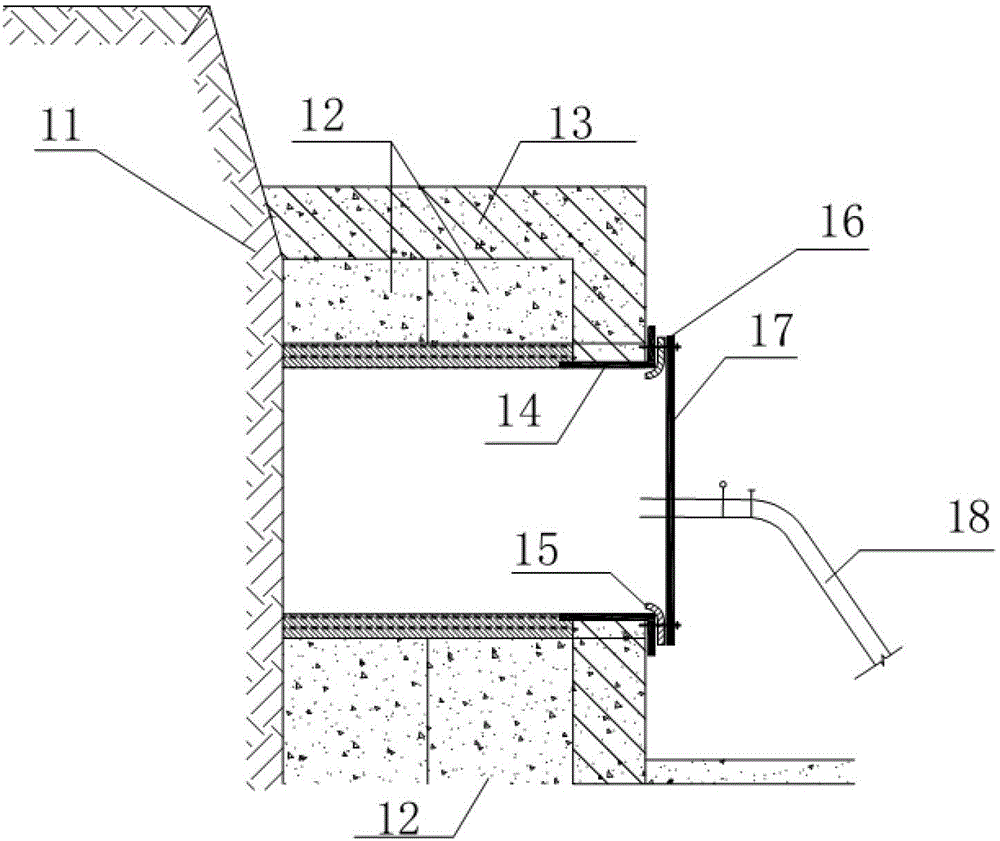

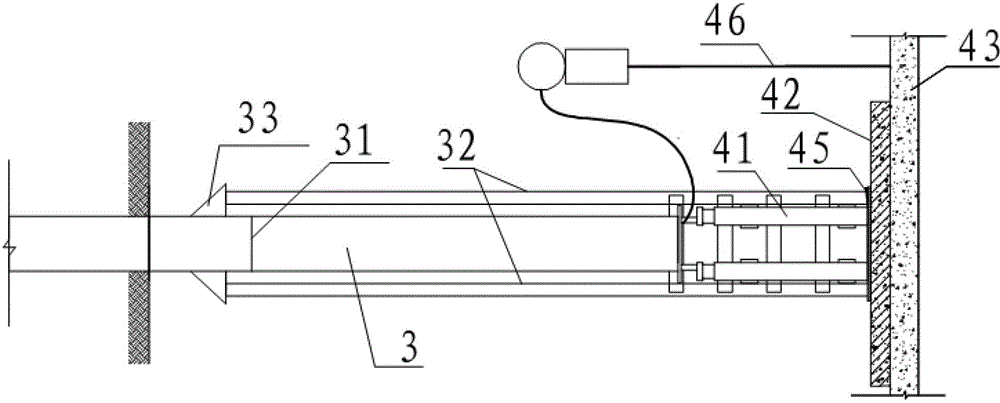

[0031] Such as Figure 1-3 As shown, a super-long pipe-curtain jacking construction device without relays in an embodiment of the present invention includes a portal 1 and a pipe-curtain steel pipe 3, the portal 1 is provided with a sealing mechanism, and the pipe-curtain steel pipe 3. The end is provided with an anti-rebound device 4. The anti-rebound device 4 includes a top pick 41 and a distribution beam 42 located at the rear end of the top pick 41. The rear end of the distribution beam 42 is provided with a back beam 43 connected to the back Pile 44, the top pick 41 is connected with the distribution beam 42 through a steel wedge 45, and the back pile 44 is provided with a mud inlet and discharge pipe leading to the outside of the pipe curtain steel pipe 3; the sealing mechanism includes the soil body 11, located on The rotary grouting pile 12 and the grouting pipe 18 on the outside of the soil, the water stop wall 13 is arranged above the rotary grouting pile 12, the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com