Thrust valve device

A valve device and thrust technology, applied in the direction of valve device, sliding valve, engine components, etc., can solve the problems of reducing sealing torque and valve stem operating torque, assembly difficulties, etc., to reduce pressure, prolong the life of parts, and reduce operation The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

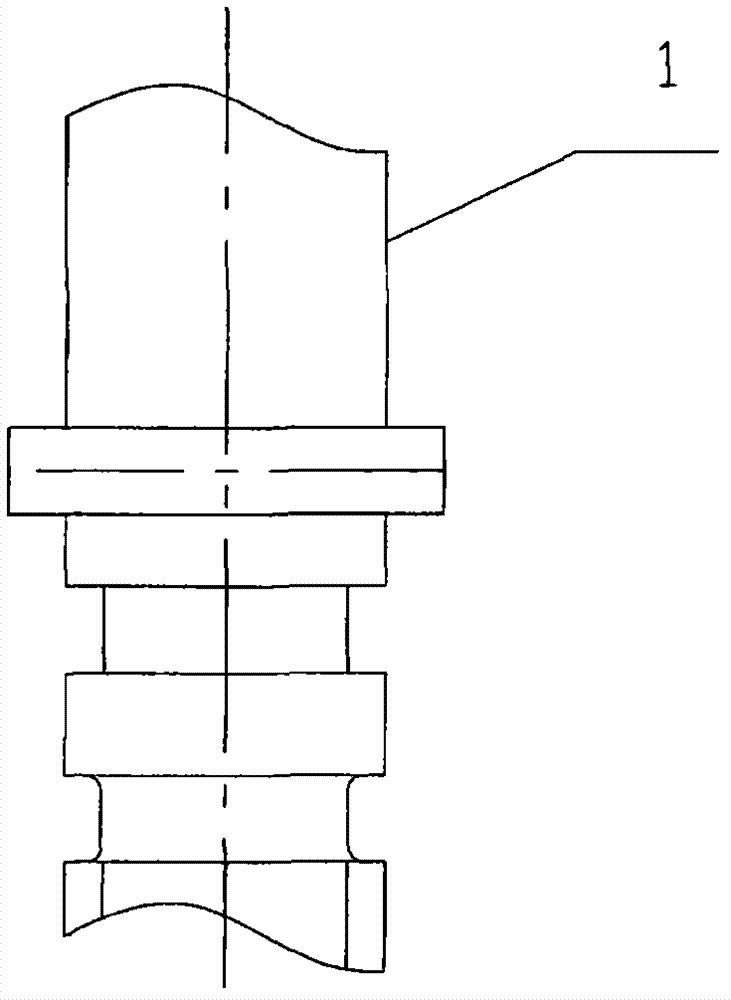

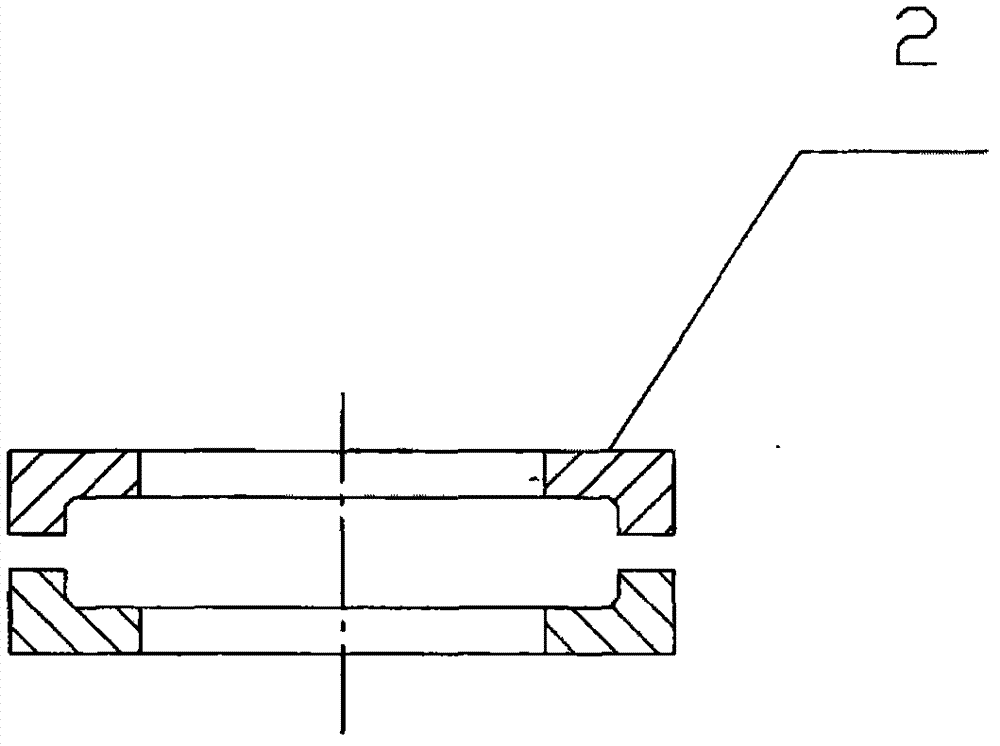

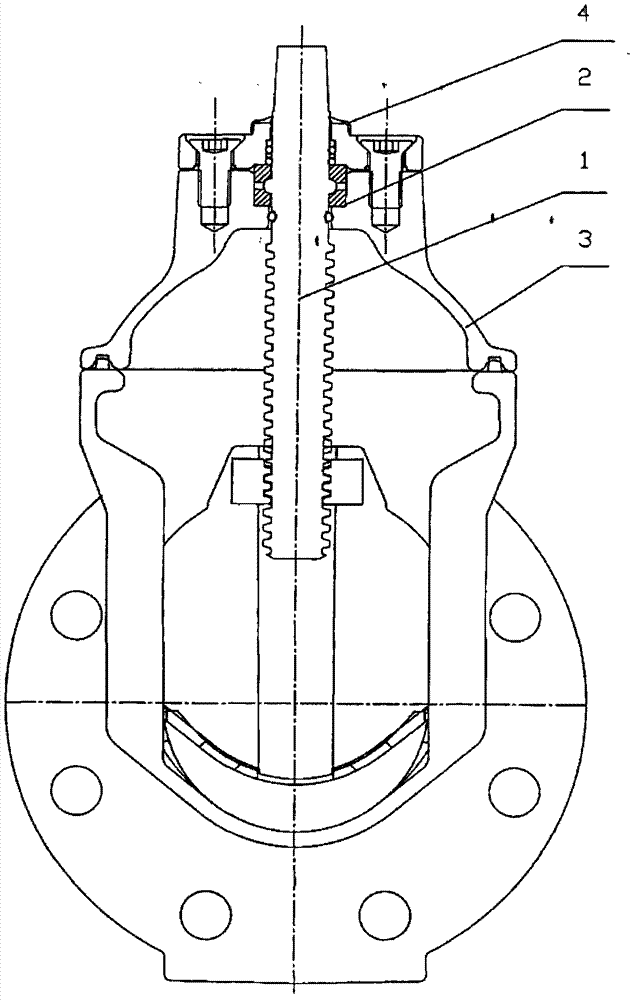

[0018] figure 1 and figure 2 Shown is the valve stem and thrust ring in the existing thrust valve device mentioned in the previous background technology section, from which it can be seen that the thrust protrusion on the valve stem 1 and the thrust concave on the thrust ring 2 The cross-section of the groove is rectangular, and when the two are in matching use, their mutual contact is surface contact, the friction force is large, the torque to operate the valve stem 1 is large, and the wear of the parts affects the service life; because the cross-section is rectangular, it is difficult to install .

[0019] In the present invention, in order to reduce the operating torque of the valve stem 1, the contact friction between the thrust protrusion and the thrust groove is reduced, such as Figure 5 and Figure 6 As shown, the upper outer peripheral surface of the valve stem 1 is radially provided with a thrust protrusion whose cross-section is an arc of R angle; Arc thrust gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com