Main steam temperature predictive control method of ultra supercritical unit of thermal power plant

A technology for ultra-supercritical units and thermal power plants, which is applied in control systems, adaptive control, general control systems, etc., and can solve problems such as difficulty in understanding the meaning of advanced control algorithms and lack of correlation between system characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below through embodiments in conjunction with the accompanying drawings.

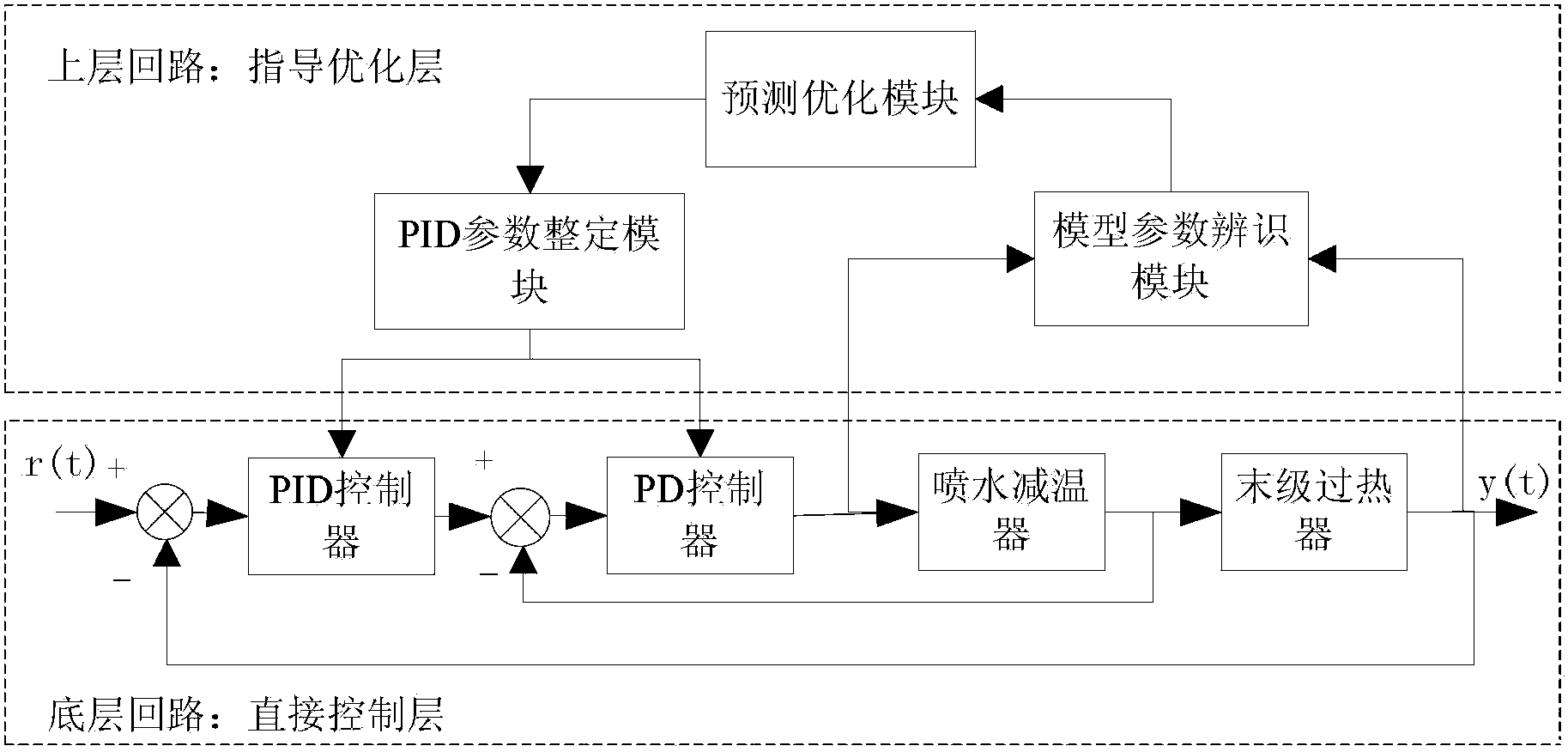

[0047] The invention has a layered control structure, which is composed of two loop controls, the direct control at the bottom layer and the direct optimization at the upper layer. The upper layer is the guidance optimization layer, including model parameter identification module, prediction optimization module and PID parameter tuning module, respectively realizing model parameter identification, prediction optimization and PID parameter tuning functions.

[0048] The direct control loop at the bottom layer is a cascade system structure, and the bottom layer includes two loop controls, the main loop and the secondary loop. The PID controller for the DCS system is still used.

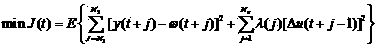

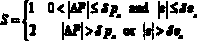

[0049] The underlying direct control loop control introduces a generalized control algorithm, and the performance index at time t is the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com