Pressure sensor

A pressure sensor and pressure technology, which is applied in the direction of fluid pressure measurement using piezoelectric devices, can solve problems such as damage to seals, and achieve the effects of increasing strength, improving fragility, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

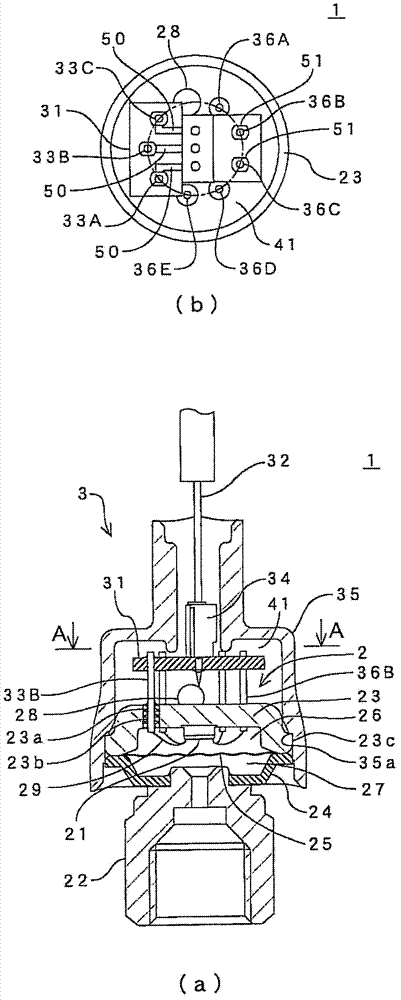

[0042] Hereinafter, modes for carrying out the present invention will be described in detail with reference to the accompanying drawings.

[0043] figure 1 Showing one embodiment of the pressure sensor of the present invention, the pressure sensor 1 includes: a pressure detection part 2 having a pressure detection element 21 inside and connected to a fluid inflow part 22; and a joint connection part 3 of the joint The connection portion 3 surrounds the pressure detection portion 2 and accommodates a wiring board (hereinafter referred to as a “substrate”) 31 to be connected to the pressure detection element 21 and an external output lead wire 32 .

[0044] The pressure detection unit 2 includes: a pressure detection element 21 ; a base 23 ; a carrier member 24 arranged opposite to the base 23 ; Liquid (oil) is sealed in the pressure-receiving space 26 between the base 23 and the diaphragm 25 . The pressure detection element 21 is fixed to the base 23 inside the pressure-recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com