Combined driving device for performing rotational motion and reciprocating linear motion and linear motor with reduced inertia

A technology of reciprocating linear motion and linear motor, applied in electromechanical devices, electric components, magnetic circuit rotating parts, etc., can solve the problems of inflexible drive devices, etc., and achieve the effect of saving weight and small inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The examples described in detail below are preferred embodiments of the invention.

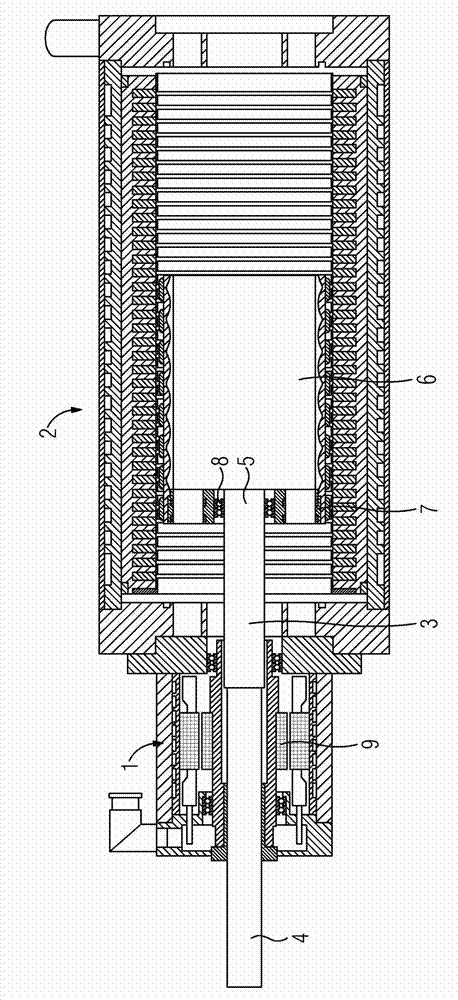

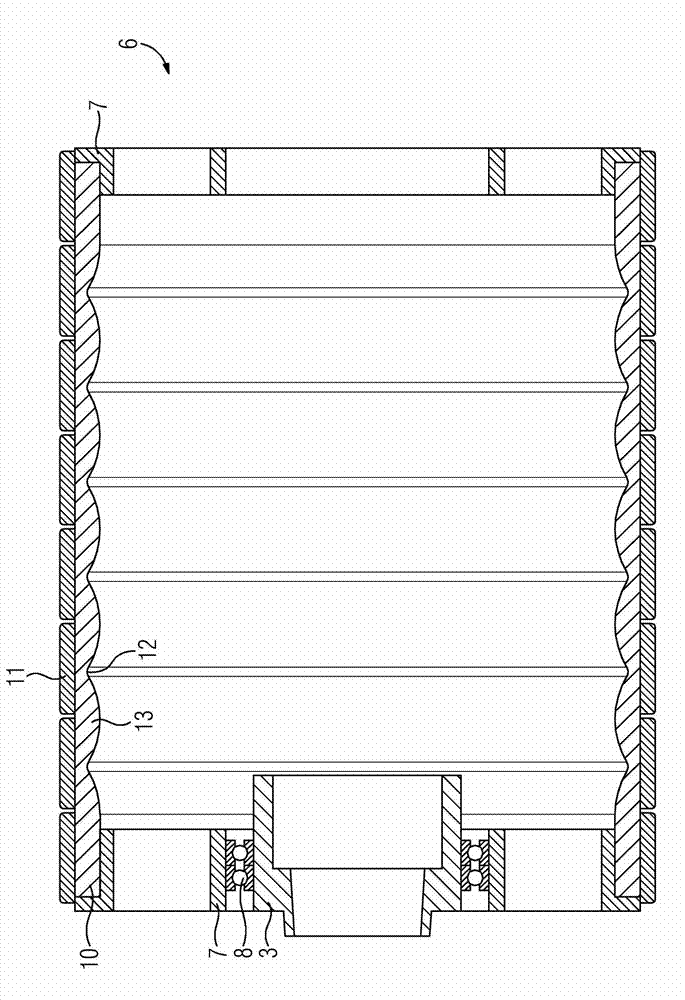

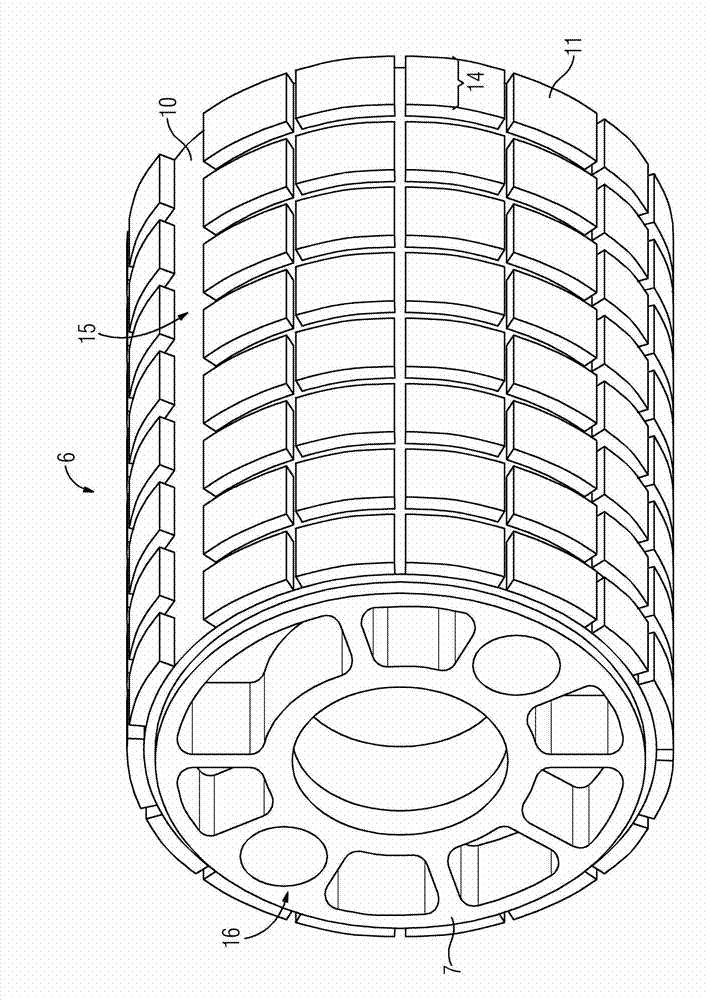

[0047] figure 1 The combined drive for rotary and reciprocating linear movements shown in can be used, for example, in machine tools or robots. It has a rotary motor 1 and a linear motor 2 . Both drive the working axis 3 .

[0048] The combined drive has an output, via which the active power is supplied. exist figure 1 In the embodiment of , the output device is on the left, and the corresponding active power is provided by the working shaft 3 . Accordingly, the working shaft 3 has an output side 4 and a drive side 5 .

[0049] The rotary motor 1 (electric motor for performing a rotary movement or rotary motor) is located closer to the output of the combined drive than the linear motor 2 . However, this also means that the rotary motor 1 is located closer to the output side 4 of the working shaft 3 than the linear motor 2 .

[0050] The working shaft 3 here passes completely thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com