Drive motor for an electric vehicle

A technology for electric vehicles and electric motors, applied to electric vehicles, motors, vehicle components, etc., can solve problems such as reducing the centrifugal strength of motor rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

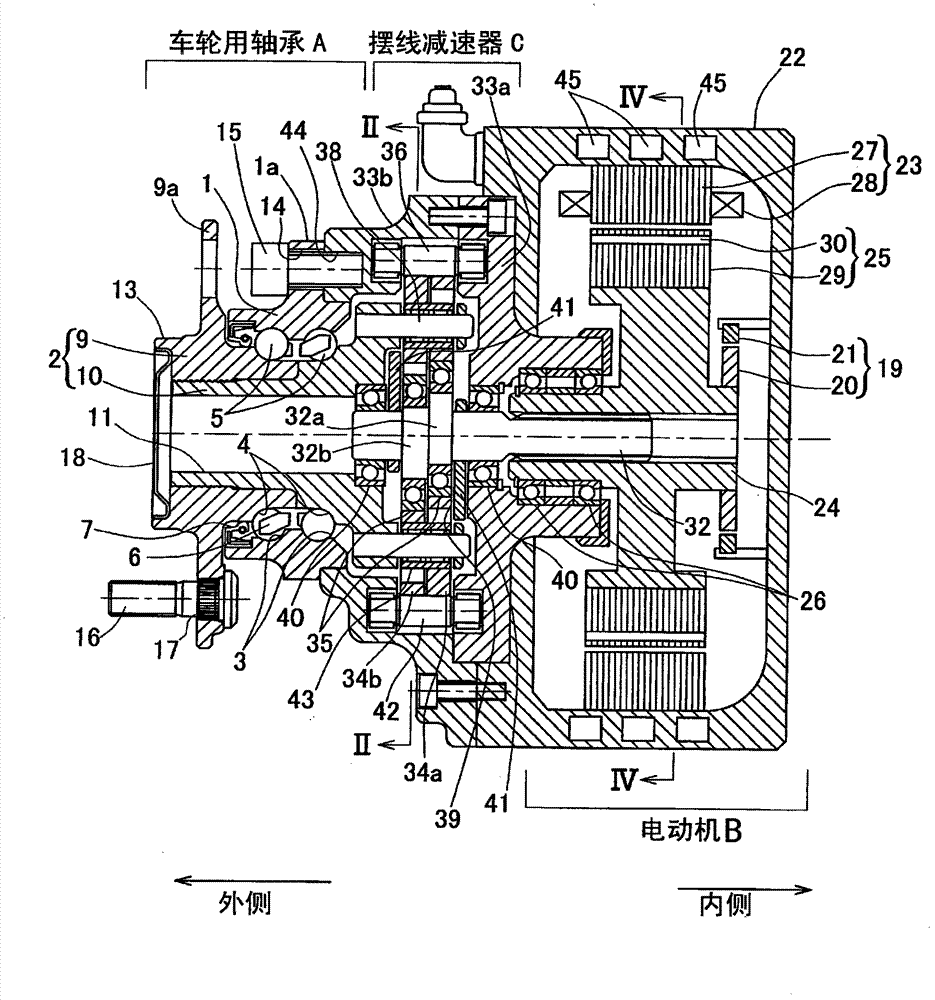

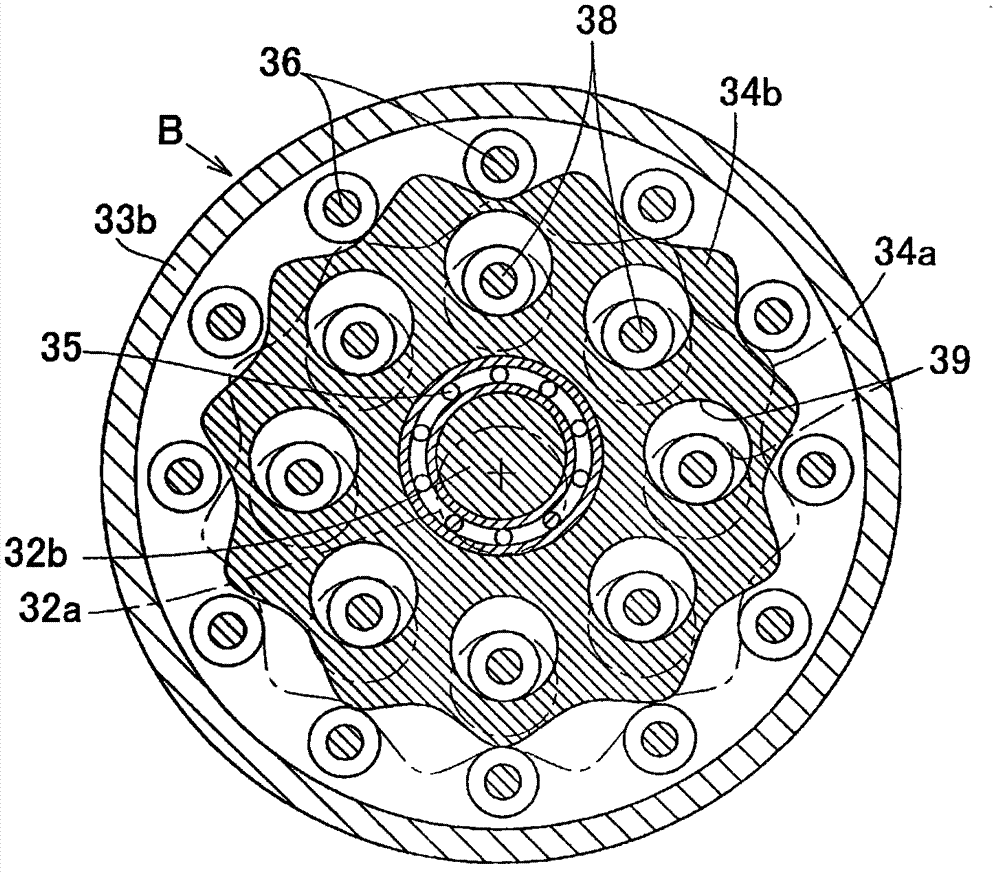

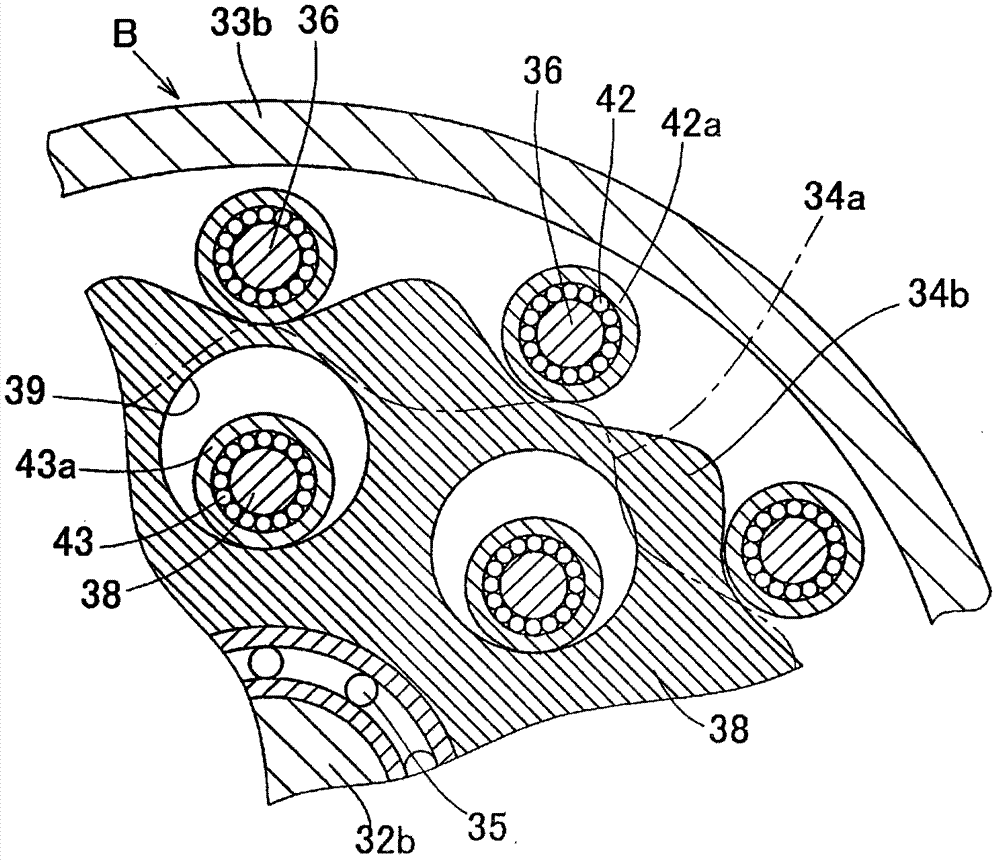

[0029] Figure 1 to Figure 4 The first embodiment of the present invention is shown. figure 1 It is a longitudinal cross-sectional view showing a wheel bearing device equipped with a driving motor of an electric vehicle according to this embodiment. This wheel bearing device is an inner wheel type motor built-in wheel bearing device, in which a speed reducer C is interposed between the wheel bearing A of the vehicle and the driving motor B of this embodiment, and is supported by the wheel bearing A. The hub of the driving wheel and the rotation output shaft 24 of the driving motor B are connected on the same axis. The speed reducer C is a cycloid speed reducer, which has a structure in which eccentric portions 32a, 32b are formed on the rotation input shaft 32 coaxially connected to the rotation output shaft 24 of the drive motor B, and Curved plates 34a, 34b are attached to the portions 32a, 32b via bearings 35, respectively, and the eccentric motion of the curved plates 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com