Cage raised pigeon automatic feeding device

A feeding device and a technology for raising meat pigeons, which are applied in the poultry industry, application, animal husbandry, etc., can solve the problems of reduced feed intake, large investment in feeding pigeons, difficulty in increasing the feeding scale, etc., and achieve a short feeding process time , Less labor input, good breeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

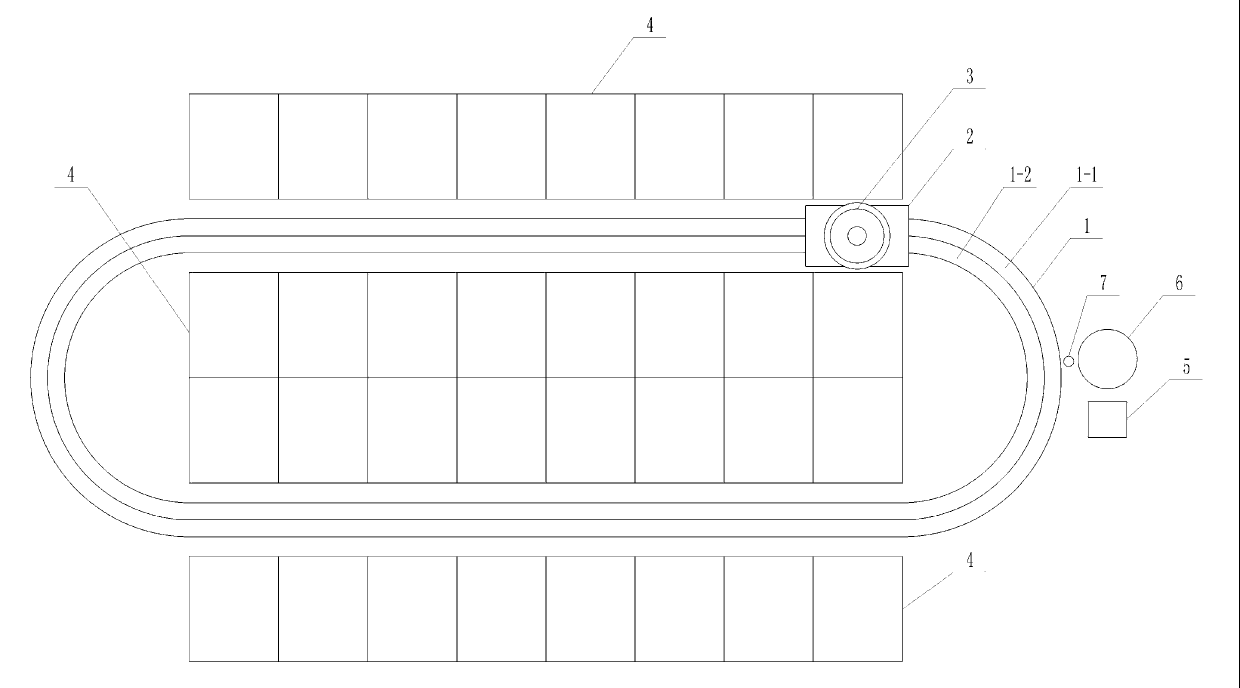

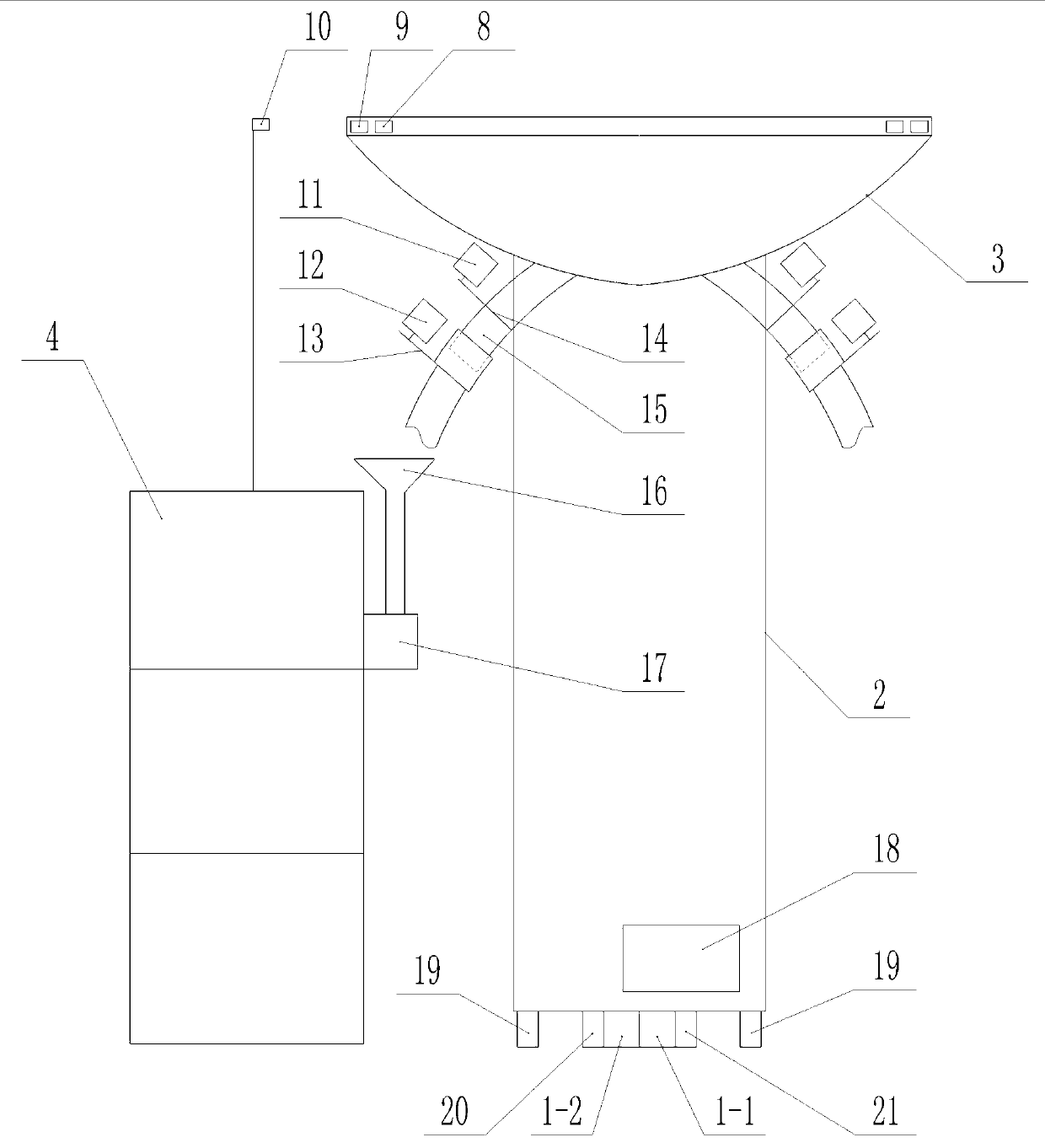

[0029] refer to Figure 1-Figure 4 , an automatic feeding device for caged meat pigeons, comprising

[0030] The feeding cart 2 and the driving guide rail 1 matched with it, the feeding cart 2 is provided with an accompanying hopper 3, and a transition chamber 15 is formed between the feeding door 14 and the discharging door 13 of the accompanying hopper 3, and the feeding The material gate 14 is connected with the feed gate electromagnet 11, the discharge gate 13 is connected with the discharge gate electromagnet 12, the feed gate electromagnet 11 is connected with the feed gate proximity switch 9, the discharge gate electromagnet 12 is connected with the discharge gate Proximity switch 8 is connected, feed door 14 and discharge door 13 are provided with reset springs, feed door proximity switch 9, discharge door proximity switch 8, feed door electromagnet 11, discharge door electromagnet 12 and control device connect;

[0031] Food trough, every group of pigeon cages 4 is ...

Embodiment 2

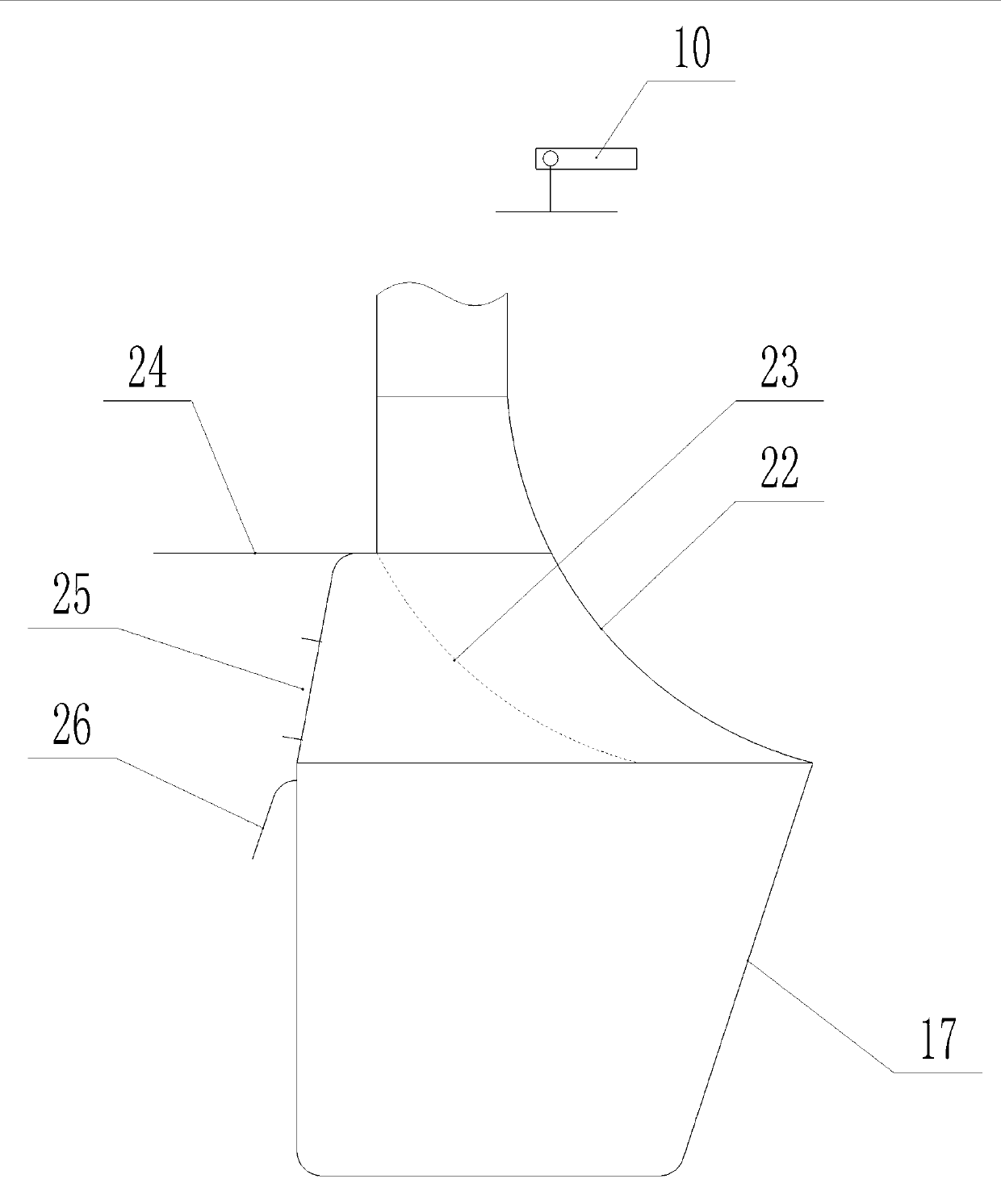

[0054] refer to Figure 5 , the food trough comprises a tank seat 27 and a tank body 17, the tank base 27 is rotatably connected with the tank body 17, the back of the tank body 17 is provided with a feeding port 25, and the feed port 25 and the feeding port of the tank body 17 are provided with There is a buffer baffle 23, and an antifouling baffle 24 is provided above the feeding port of the tank body 17. The tank base 27 is rotatably connected to the tank body 17 through a rotating shaft 29, and the tank body 17 is provided with a return spring 28 to connect with the tank base 27 , when the trough is empty, under the action of the return spring, the feeding port of the trough is upturned, which can be detected by the proximity switch. When the feeding cart 2 passes by, it will automatically discharge; when there is feed in the trough , the feeding port of the food trough descends and cannot be detected by the proximity switch. When the feeding cart 2 passes by, it will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com