Spraying machine and air supply spraying device thereof

A spray device and air supply technology, applied in the field of high-efficiency air supply spray devices, can solve the problems of poor uniformity of wind speed, small wind conveying distance of fans, large loss of air volume, etc. The effect of uniform performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

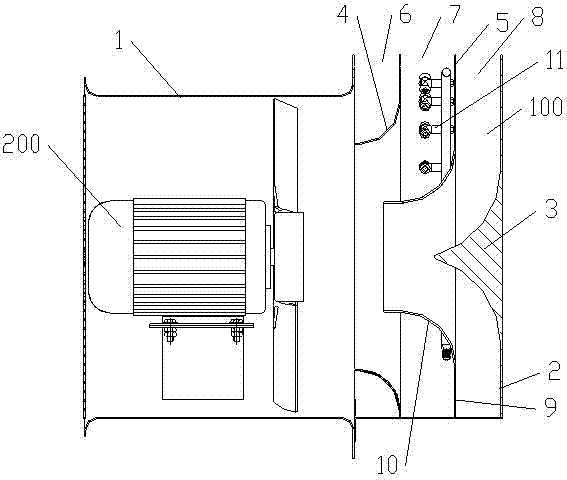

[0022] see figure 1 The sprayer includes a wind spraying device 100 and an axial flow fan 200 arranged in the axial flow cylinder.

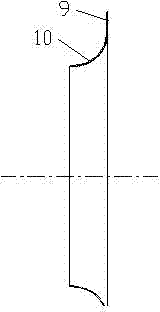

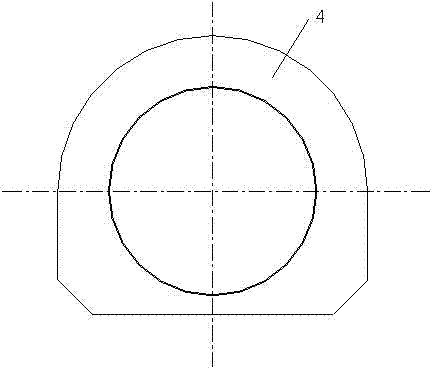

[0023] The air-driven spraying device includes a back plate 2 opposite to the outlet of the axial flow air cylinder 1, and a guide cone 3 coaxial with the axial flow air cylinder is arranged on the back plate. The back plate 2 and the deflector cone 3 are integral to form a windshield. A first flow guide plate 4 and a second flow guide plate 5 are also arranged between the axial fan cylinder and the back plate. 5 and the diversion guide of diversion cone 3 form three parts of radial airflow. The three radial airflows flow out from the first, second and third air outlets 6, 7 and 8 respectively. The first air outlet 6 is formed between the housing of the axial fan cylinder and the first diversion guide plate; the second air outlet 7 is formed between the first diversion guide plate and the second diversion guide plate, and the second diversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com