Roll crusher

A roll crusher and frame technology, which is applied in the direction of grain processing, can solve the problems of crushing and crushing damage, failure to achieve the crushing effect, and difficulty in cleaning the crushing roller, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

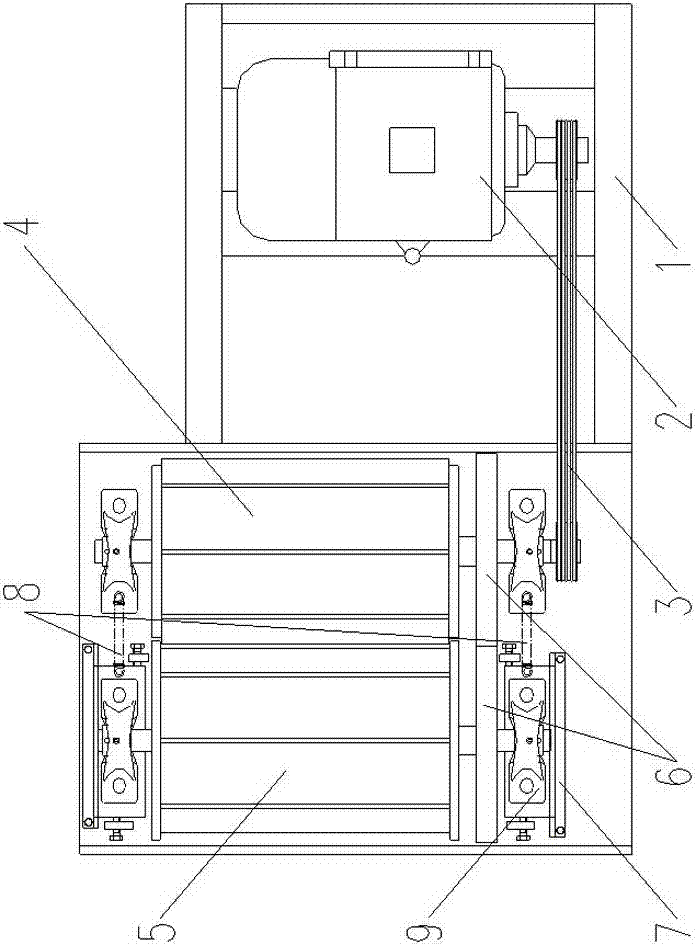

[0011] Embodiment 1: As shown in the drawings, a roller crusher includes a frame 1, a drive motor 2, a transmission belt 3, a driving roller 4 and a driven roller 5, a transmission gear pair 6, a guide rail 7, and a spring 8. The driving roller 4 and the driven roller 5 rotate in opposite directions. The driving roller 5 is fixedly installed on the frame 1 and connected to the driving motor 2 through the transmission belt 3. The driving motor 2 drives the driving roller 5 to rotate counterclockwise, and the driven roller 5 The transmission gear pair 6 is connected with the driving roller 5 and is driven by the driving roller 5 to rotate clockwise. The material falls between the two rollers from above the driving roller 4 and the driven roller 5. 5. The bottom discharge, which constitutes the main working structure of the crusher. At the same time, the bearing blocks 9 at both ends of the driven roller 5 are respectively connected to the guide rail 7, the guide rail 7 is fixed ...

Embodiment 2

[0013] Embodiment 2: basically the same as Embodiment 1, the difference is that the guide rail 7 is vertically perpendicular to the driving roller 5, and the spring 8 drives the driven roller 5 to move up and down along the guide rail 7, automatically adjusting the driving roller 4 and the driven roller 5 broken gap between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com