Bearing structure and motor with same

A technology for bearings and outer rings of bearings, applied in the field of bearing structures and motors with them, can solve problems such as rotor scraping, increased ball wear of bearing structures, affecting motor shaft noise, life expectancy, etc., to prevent bearing lockup and sweeping and boring Failure, reduce the effect of stress wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

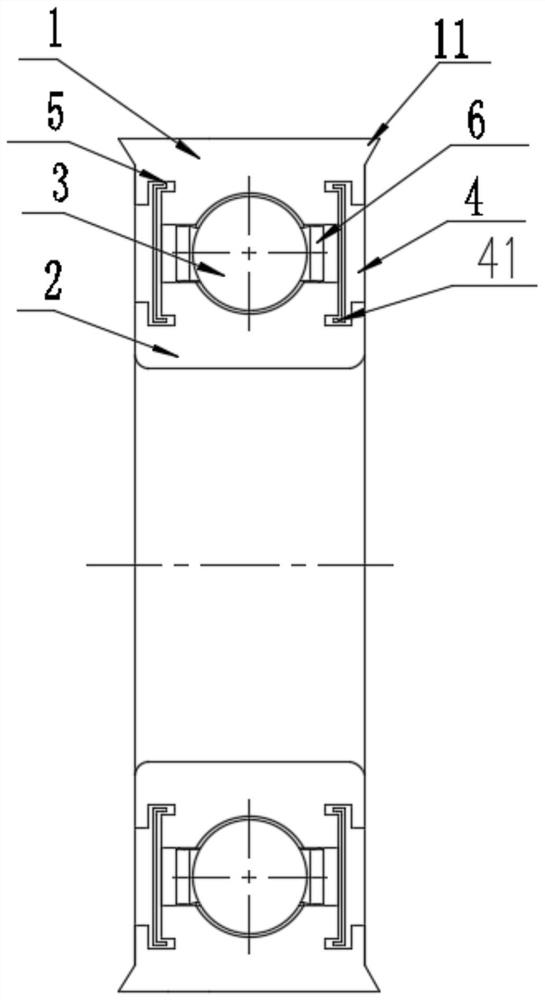

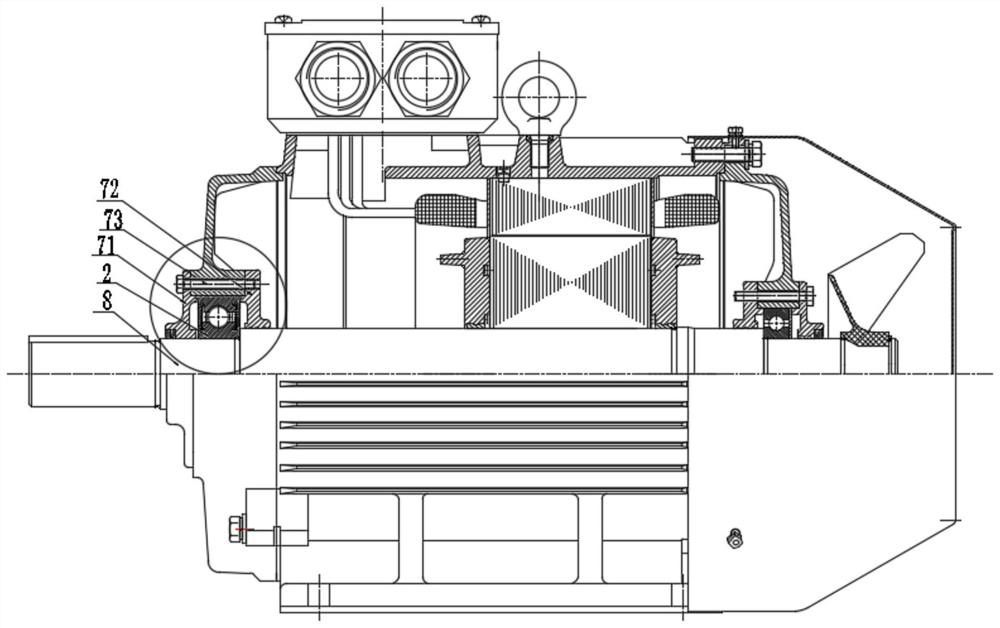

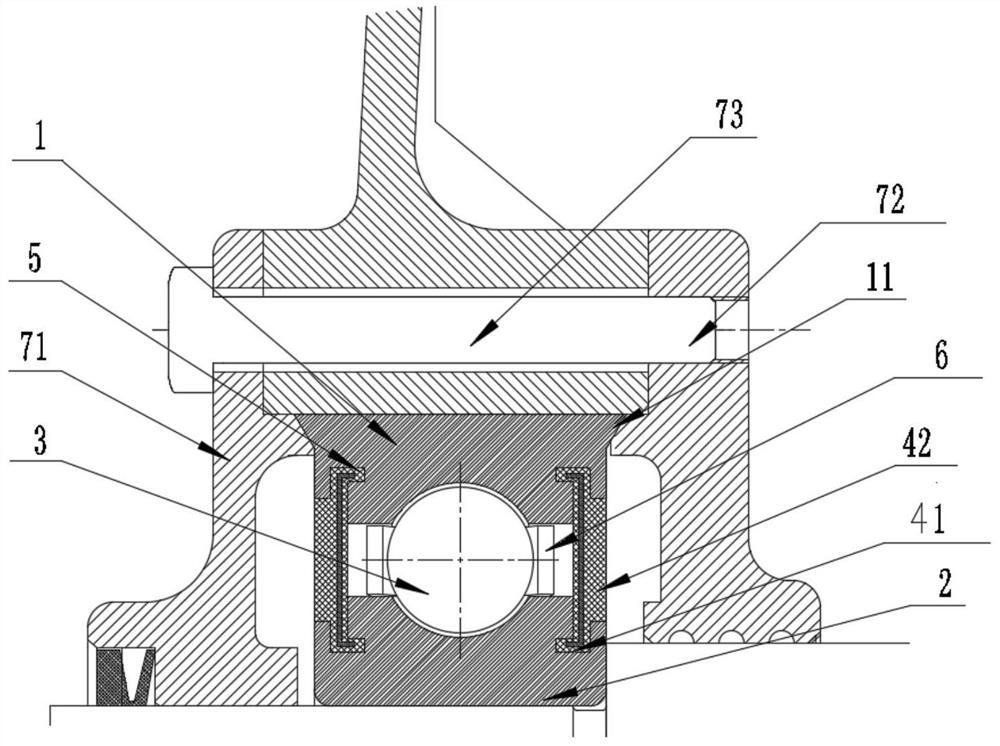

[0027] see in conjunction Figure 1-4 As shown, a bearing structure includes a bearing inner ring 2, a bearing outer ring 1, a rotating structure 3 and a supporting structure 4, and the rotating structure 3 is arranged between the bearing inner ring 2 and the bearing outer ring 1; the supporting structure 4 can support the bearing The outer ring 1 is supported so that the gap between the bearing outer ring 1 and the rotating structure 3 is within the first preset gap range; the application uses the support structure 4 to support the bearing outer ring 1, even if the external force of the bearing is uneven Or when the rotating structure 3 is deformed, the gap range between the bearing outer ring 1 and the rotating structure 3 can also be guaranteed. When running in the limit range, the force on the rotating structure 3 can be avoided or reduced, and the supporting force can be provided to reduce the force on the rotating structure 3 wear, improve the life of the bearing, and au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com