Device for automatically adjusting gap between lead screw nut and movable crossbeam of planer type milling and boring machine

A technology for moving beams and screw nuts, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems affecting product processing quality, unstable transmission, damage to machine tools, etc., to achieve long service life and stable operation. , to eliminate the sinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

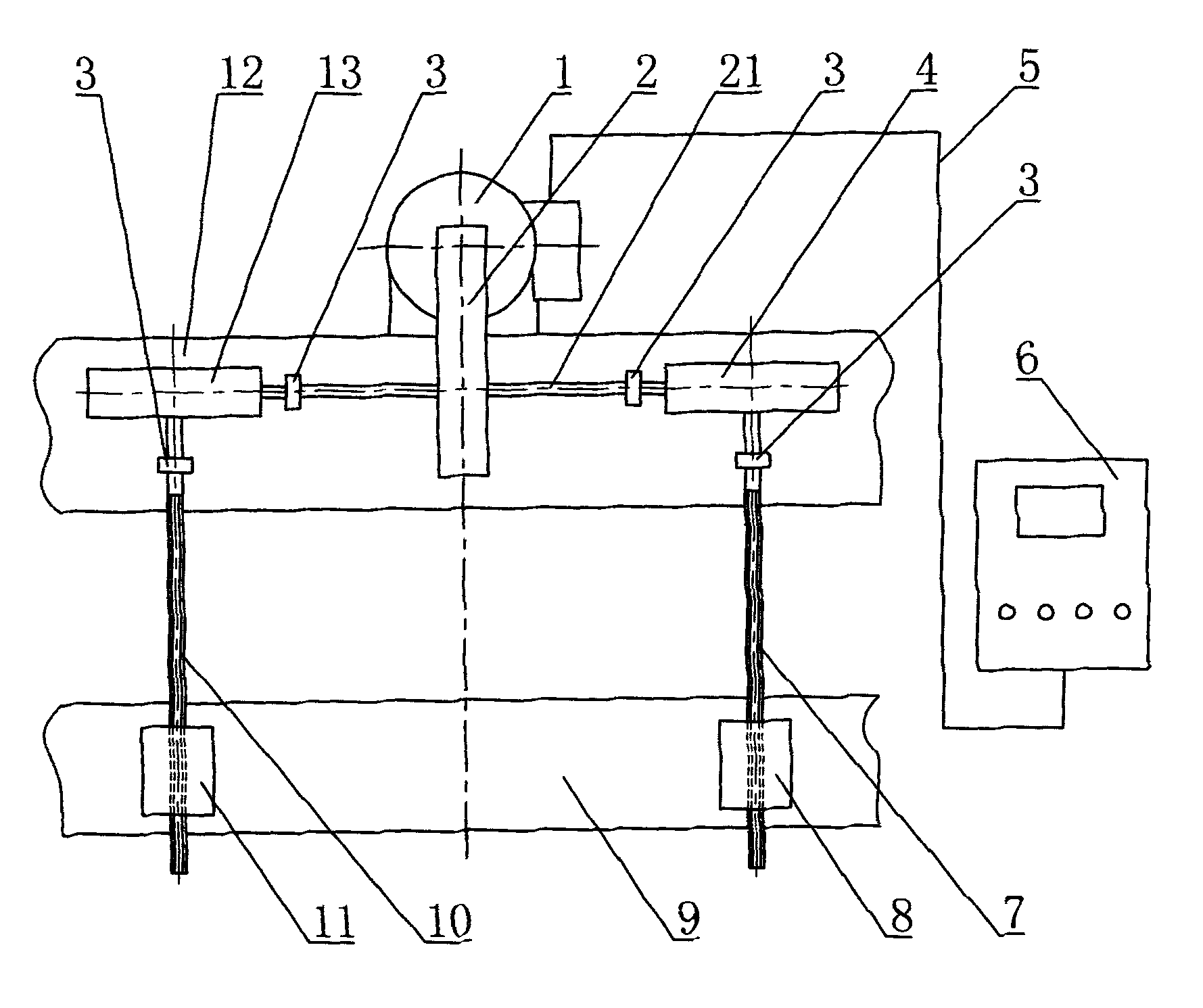

[0007] see figure 1 , the automatic gap adjustment device of the gantry milling and boring machine for moving the beam screw nut of the present invention includes a motor 1, a double output shaft worm gear reducer 2, four couplings 3, a right output shaft worm gear reducer 4, a right screw 7, a right Nut 8, left leading screw 10, left nut 11 and left output shaft worm gear reducer 13 also include electric control box 6, and described electric control box 6 is connected with motor 1 by lead 5, and is installed in described electric control box 6 There is a PLC, the motor 1 is connected to the worm shaft of the double output shaft worm gear reducer 2, and the two ends of the double output shaft 21 of the double output shaft worm reducer 2 are respectively connected to the left output shaft through the coupling 3 The worm shaft of the worm gear reducer 13 and the worm shaft of the right output shaft worm reducer 4 are connected, and the left output shaft worm reducer 13 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com